Washing machine belt: types, selection and troubleshooting

A belt in a washing machine is needed to transfer rotation from the engine to the drum or activator. Sometimes this part fails. We will tell you why the belt flies off the drum of the machine, how to choose it correctly and replace it yourself.

Description

If your washing machine is not equipped with a direct drum drive, a belt drive is used to transmit the rotation from the motor. The peculiarity of her work is that she works like a reducer. The engine develops a speed of 5000–10,000 rpm, while the required operating speed of the drum is 1000–1200 rpm. This imposes certain requirements on the belt: it must be strong, elastic and durable.

During washing, especially with a full load, considerable forces are exerted on the drive elements. In addition, vibration can occur at high speeds. Therefore, the belt serves as a kind of fuse. If it flew off, then the load on the drum is higher than the maximum permissible. And the additional force is not transferred to the motor, and it is completely protected against overload.

The service life of a quality belt is 10 years or more. But it is influenced by the operating conditions of the machine, the frequency of its use, the correct installation and the microclimate in the room itself.

Naturally, drive parts are subject to wear. This is especially true of the belt, because it is not metal, but rubber. Here are a few of the salient features, sorted as they appear:

- squeaking and rubbing sounds;

- uneven rotation of the drum, with jerks and vibration;

- the machine can only wash a small amount of laundry;

- an error code is displayed on the display;

- the engine is running exactly, but the drum is not spinning.

Therefore, sometimes there is a need for replacement.

Anyone who knows how to hold a screwdriver can make such a repair. And it is better not to postpone the work, well, or not to use the machine until the repair. The parts work at high speed, and if the belt breaks and flies off on the go, it will hit a random place with great force. And you’ll be lucky if it’s the back wall.

Before removing the old belt and installing a new one, it is advisable to familiarize yourself with the technical parameters of the machine. The fact is that there are several types of belts, and they are not interchangeable.

Views

All information regarding the belt is painted on its non-working side. But sometimes the inscription is erased and it is impossible to read it. Then you will have to look for information in other sources or bring a sample to the seller. But it is not difficult to determine the required parameters on your own. To do this, you need to use their classification.

Along the transverse profile

They are of several types.

- Flat. They have a rectangular cross-section. They were used only in very old cars, now they are completely superseded by poly-V-ribbed ones.

- Wedge... They have a cross-section in the form of an isosceles trapezoid. Foreign belts are designated 3L, domestic belts - Z and A. Rarely found in modern washing machines.

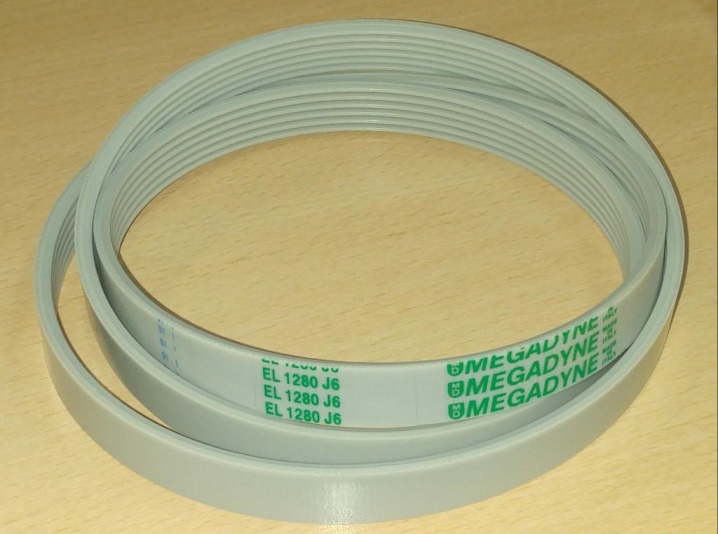

- Poly-V-ribbed. They have several wedges arranged in one row on one common base. This is the most common type.

The latter, in turn, come in two varieties.

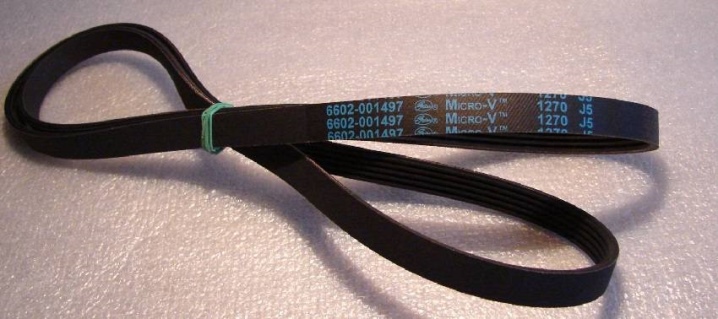

- Type J... The distance between the vertices of two adjacent wedges is 2.34 mm. They are used on large and powerful equipment, they can transfer significant forces.

- H. The distance between the wedges is 1.6 mm. Used in more compact models.

Visually, they differ in the depth of the streams and the width of one wedge. The difference is almost 2 times, so you can't go wrong.

By the number of wedges

Belts can have from 3 to 9 gussets. Their number is displayed on the label. For example, J6 means that it has 6 streams. Quite frankly, this parameter doesn't really matter. If the belt is narrow, you will need to load less laundry. With it, the likelihood of engine overload is minimal. Wide, on the contrary, allows you to fully exploit the potential of the machine. It will slip less than a narrow one. And this will increase the resource of the pulleys.

When choosing, it is better to take the belt for which the machine is designed. This will make it possible to fully realize its capabilities.

By lenght

The length of the belt is indicated by numbers in front of the profile designation. It is not possible to determine the required length using a sample of an old belt. This value is indicated in a stretched, that is, loaded position. It will be larger than the one that you measure from the old sample.

Please note that rubber and polyurethane belts have different elasticity. Rubber is more rigid.

Belts made of different materials are not interchangeable, although they have the same working length. A tougher rubber will simply not fit on the drive elements, or installation will be very difficult. By the way, the pulleys are made of brittle metal and the additional force generated during installation may not be able to withstand.Alternatively, the rubber specimen should be slightly longer. But then slippage is possible. But this is only relevant for old washing machines. New ones are equipped with an elastic polyurethane belt, with the replacement of which there are no problems.

The required length can be determined by putting rope on the pulleys and then measuring it.

For your convenience, we have compiled a small table, which contains examples of belt designations and their decoding.

- 1195 H7 - length 1195 mm, distance between wedges - 1.6 mm, number of streams - 7.

- 1270 J3 - length 1270 mm, distance between wedges - 2.34 mm, number of streams - 3.

Manufacturers usually use the same belt size. This greatly simplifies the choice. The most popular Samsung washing machines are equipped with a belt with the designation 1270 J. For narrow machines they have 3 streams (designation - 1270 J3), for medium and wide - 5 (1270 J5). Most BOSCH washing machines are equipped with a belt marked 1192 J3.

Now that you have this knowledge, you can safely go to the store.

Selection rules

There are many externally similar belts on sale, from which you need to choose the right one. For this, we have provided general advice.

- If the markings remain on the old one, you need to choose a similar one. If it is not there, use the above classification or find the information you need in the machine's passport.

- When choosing, pay attention to quality. The polyurethane belt should stretch well and should not show white streaks when stretched.

- Better buy a belt, which is reinforced with nylon or silk threads. It will be just as easy to dress, but even with heavy wear and tear at speed is unlikely.

- Dimensions play an important role. Even small deviations provoke either slippage or too much tension. All this will shorten the service life of the machine.

- And buy belts only in specialized stores of household appliances... It is impossible to determine the composition of the material at home, and it is possible to calculate a fake only after installation.

If the belt flies constantly, this is a reason to look for the cause in the washing machine itself.

Causes of malfunctions and remedies

There may be several problems with the drive of the machine.

- Normal wear and tear of the product. During operation, the belt stretches, begins to whistle, and then breaks. This is especially evident during spinning, when the drum rotation frequency is highest. Then only a replacement is needed. The simplest malfunction.

- Loose pulley attachment to the drum. With prolonged operation, the fastening of the pulley to the drum or activator may weaken, the connection begins to creak, as a result of which backlash may appear. You can eliminate this malfunction by tightening the fasteners and then filling the bolt or nut with a special sealant. This is necessary to lock the screw, without it, the screw will loosen again.

- Pulley defects... It may have burrs or significant dimensional deviations. Then you need to buy a new part. In this case, it is difficult to repair the machine with your own hands, since a sealant is used to fix the pulley attachment nut.

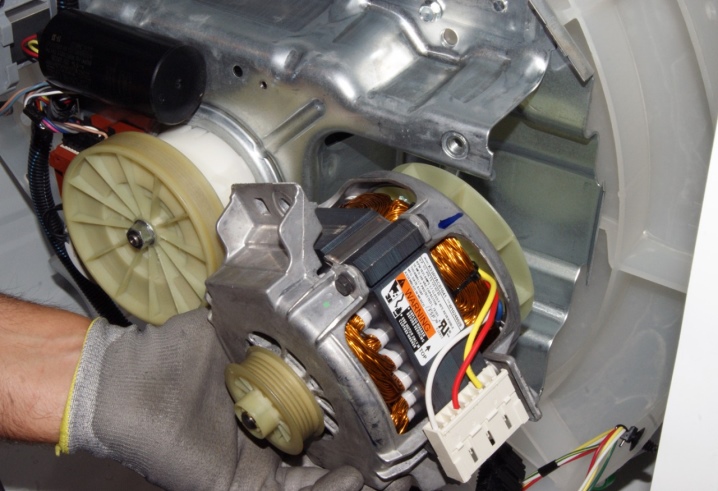

- Defective motor mount. The engine is mounted on rubber shock absorbers that dampen vibrations. Sometimes the mount is loose, and the amplitude reaches a large value. Then the fastening screws need to be tightened. Or, as one of the reasons, the resource of the rubber cushion has developed, it has cracked or hardened. In this case, the shock absorbers are replaced with new ones.

- Deformation of the motor shaft or drum pulley. This can be determined by rolling the questionable knot with your hand. There should be no radial and axial runout. The defective part must be replaced.

- Bearing wear. It causes the drum to skew, causing the belt to slide off. Typical signs are noise during operation and the appearance of backlash in the drive. Then you need to install new bearings and grease them with thick grease. Liquid will not work. It is advisable to invite a specialist for this work.

- Incorrect machine installation. It should be installed strictly according to the level and without distortions. Incorrect installation leads to unbalanced moving parts and uneven wear.

- Microclimate in the room. Too humid air causes the rubber parts to delaminate. Too dry leads to cracking. It is necessary to monitor the humidity of the air using hygrometers.

- Rare use of a typewriter. If it does not work for a long time, the rubber parts dry out and lose elasticity. Then, when you try to turn on, there is a high probability of the belt coming off or breaking. It is recommended to run the washing machine periodically, you do not even need to wash it.

The correct choice can be confirmed by installing the belt on the machine.

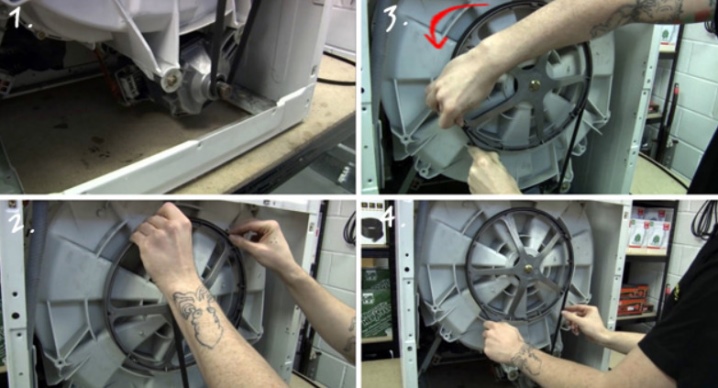

- Remove the rear cover. It is secured with several screws.

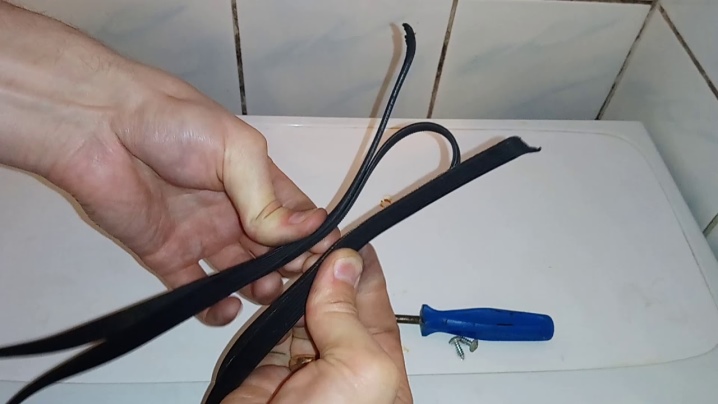

- Remove the old belt (or the remnants of it). To do this, pull it towards you with one hand, and with the other, rotate the pulley counterclockwise. If it does not give way, then the belt is hard - to dismantle it, you need to loosen the engine mount.

- Check the pulley for play. To do this, shake it slightly. There should be no backlash or it should be minimal.

- Inspect the working planes of the pulleys for cracks. If they are, the part needs to be changed: it will not withstand rotation at high speed. To do this, you can use your smartphone in video recording mode.

- The belt is first put on the motor shaft and then on the drum... The operation is the same as putting on the chain on a bicycle. You need to turn the shafts counterclockwise.

- Check the belt tension, it should not be too tight. But sagging is also unacceptable. If so, the new belt will not fit.

- It is difficult to put a hard belt on old washing machines.... To do this, loosen the motor mount, put on the drive and fasten it back. To properly tension the belt, it is necessary to adjust the position of the motor using screws or special shims.

- Track down that the belt is not twisted, and its wedges exactly match the grooves on the motor shaft and drum pulley.

- Try turning one of the pulleys counterclockwise, and slow down the other with your hand, imitating the load. Rotation should be, and slippage is not allowed.

- Put on the back cover and check the machine in operation.

But remember that all actions you perform at your own peril and risk.

Changing the drive belt yourself is not difficult.And if in doubt, you can always seek help from a specialist.

In the next video, you can watch the process of replacing a belt in a washing machine.

The comment was sent successfully.