Why isn't the drum spinning in the washing machine and what should I do?

If the drum of your washing machine has stopped rotating, then the reasons for this breakdown can be very different. The situation in which the wash cycle has started, but cannot be completed to the end, is rather unpleasant, but you should not panic and run after new equipment.

Today we will talk in detail about what to do if the drum has stopped, and what to do to fix the breakdown.

Causes

Everyone knows that any washing machine has a maximum weight of loaded laundry - it is indicated in the operating instructions for the equipment. Usually it is 3.5 kg, as well as 5, 7 or 10 kg. However, few users weigh things before loading, preferring to determine the weight "by eye". If the load is close to the maximum permissible threshold, then the unit collects water, but the drum is spinning too tightly, and this significantly impairs the quality of washing.

If the overload is significant, then the movement of the drum stops altogether: it does not fill in water, does not wash and does not wring out. Usually, in this case, reducing the volume of the laundry helps - just open the hatch door, empty the tub by half, and start the wash again. Most often, this measure is quite enough, and the user can breathe a sigh of relief - this is not a technical malfunction, but a common mistake that is easy and simple to fix.

Before proceeding with the search for the source of the malfunction, you need to prepare the AGR:

- disconnect the device from the power supply - for this, it is not enough to press the shutdown button on the panel, you also need to unplug the cord from the outlet;

- find unnecessary things, rags - they should be laid out near the unit, and then open the filter, you can put a volumetric, but low capacity under it;

- after you have drained all the liquid, you need to get out the loaded laundry and start diagnosing the breakdown.

As a rule, experts conditionally divide all types of breakdowns into two types: common and rare. Stopping the drum of the washing machine belongs to the first category, and the reasons that cause the malfunction are typical, they can be the result of mechanical or technical influences.

If the drum stops rotating during spinning, then the laundry at the outlet will not be soapy, but damp - this indicates a malfunction of the drain pump, water control sensor, CMA control module and programmer.

If the drum hangs during the washing process, then the laundry at the exit will be soapy - most likely, the drum is simply jammed, it is possible that a foreign object has got into it, but there may also be damage to the bearing or drive belt.

All these breakdowns need to be discussed separately.

Foreign object in the tank

The simplest and at the same time common reason why the drum does not move is a stuck object. Sometimes a nail, coin, button or other small object gets stuck between the tank and the drum, which interferes with the technique to work as usual.

In order to find the cause of the malfunction, you should follow a few simple steps:

- pull out the CMA in such a way as to ensure unhindered access to it from all sides;

- unscrew the screws, holding the top cover, and carefully remove it;

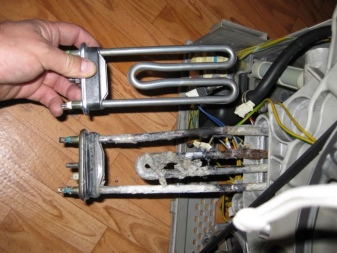

- remove the heating element and disconnect the wires going to it;

- into the resulting hole need to shine a flashlight - if a foreign object is present there, you will definitely see it.

The doors opened

In washing units with a vertical loading type, the tank flaps open from time to time during the spin cycle. Sometimes the cause of a malfunction can be careless handling of equipment - it is possible, that the child reached the typewriter and, with the flaps open, turned the drum by hand. Or maybe an adult user has loaded too much dirty laundry, and a piece of cloth hit the release button.

Such a malfunction is very dangerous, because during intensive spinning, the open blades act like knives for meat grinders, and spoil everything that they meet “on the way”.

When rotating at speed, the flaps can break through the protective barrier, the heating element is the first to suffer, and after it the walls of the drum and tank. If all these three elements fail, then such a repair will cost a pretty penny, and then it will be easier to purchase a new unit.

Rusted bearing seized

Another common cause of the CMA drum stalling can be faulty bearing. The machine jams at this moment, it stops the movement. Usually, in such situations, before the drum hangs, a sharp grinding of metal is heard - having heard it, you should immediately turn off the unit, without waiting for the moment when the element is completely broken.

The bearing can become faulty due to natural wear and tear that occurs with any technique over time.... Excessive humidity in the room where the washing machine is used, as well as the excessive use of descaling agents and plaque on the elements of the machine, can speed up the process many times over.

In addition, a malfunction can cause the oil seals to dry out.

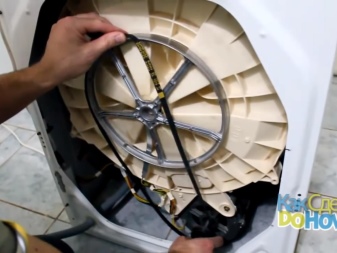

The drive belt has fallen off or deteriorated

If during washing the machine starts to hum and its drum stops, but after scrolling with your hands it easily moves in both directions, then most likely there are problems with the drive belt. Over time, it can stretch or wear out, fly off the large and small pulleys, and also come off, it is possible that it wrapped itself around, thus blocking the operation of the equipment.

Usually this happens either when the device is used too intensively, or, on the contrary, during a prolonged idle time - from inactivity, the drive belt begins to crack and is interrupted at the very beginning of the start of the wash.

The brushes of the electric motor are worn out

Another likely reason why the drum stops moving is this is the mechanical wear of the graphite brushes of the motor... As a rule, in such a case, the sound of the motor is not heard during the operation of the unit. As the operation progresses, the brushes become shortened and cease to reach the collector - as a result, a sufficient electromagnetic field is not formed, and the rotor stops rotating.

Broken control module

Today, the vast majority of SMA is controlled by an electronic module, nevertheless, the production of more primitive electromechanical models does not stop - in these devices the programmer takes over the control function. Both the programmer and the electronic control unit can break. In this case, the lack of movement of the drum complements the lack of a set of water, respectively, the wash does not even start. Moreover, this happens not because the device is technically unable to perform this, but because it simply does not receive the appropriate command.

The reasons for the failure of the software module are often voltage drops or physical wear of the element.

Burned out engine

A little more serious is the problem in which the drum freeze is due to a malfunction of the engine. This does not happen often, but nevertheless, the motor sometimes burns out due to leaks, as well as voltage fluctuations in the electrical network. Only an experienced craftsman can cope with such a breakdown.

One of the symptoms of such a malfunction is the fact that at idle, the drum scrolls, and when you turn on the standard wash in the house, it sharply knocks out the machines.

This often happens when the winding is bridged, since in case of any other malfunctions of the CMA, the drum simply does not rotate.

Another common reason why the CMA drum does not spin is capacitor malfunction, in many products, it is installed right next to the electric motor.

And also a breakdown of the heating element often leads to blocking of rotation.

How to fix it?

Some malfunctions in the CMA, leading to immobility of the drum, can be corrected on their own without contacting the master. However, it should be noted that not everyone succeeds in doing this.

If a foreign object is found in the drum, then you need to perform several diagnostic manipulations and try to remove it outside. First, take a good flashlight and try to locate the item. For maximum visibility, you can try to stick your head into the open hatch of the SMA, and place the flashlight, when turned on, inside the unit so that it illuminates the interior space well. Usually, such a study gives a good result, and all unnecessary items are quickly found.

So, if a "bone" from lingerie or a similar object is stuck in any of the perforated holes, you will definitely see it, in which case it will be quite easy to pull it out. You need pliers, they need to grab the protruding end - and the foreign body will be removed.

If the interference is invisible, or you cannot get it through the hole in the drum, then you can try to remove the stuck object through the niche where the heating element is attached.

If you think that the cause of the malfunction is related to the drive belt, then you need to remove the rear panel of the CMA and see in what technical condition this element is. If the belt has fallen off, then you need to return it to its original position, and start washing again. Most likely, this will be enough, but as practice shows, such a measure is only temporary, and after a while the stretched belt flies off again. Try to change it to a new one as soon as possible.

If the drive belt breaks or breaks, then the issue of repair will not be postponed for the long term - you need to purchase a new element so that it exactly matches the old one in length, number of wedges and markings.

If the control unit malfunctions, there are three options for solving the problem - replace the unit completely, reset the program and perform a "flashing".

To carry out repairs, special skills will be required, since during the work it will be necessary to check the physical parameters of the elements and track the circuits. If one of the following signs is found, professional intervention is necessary:

- the shade has changed in some areas, the tracks have darkened, and tan marks are also noticeable;

- there are bulges on the caps of the capacitors;

- the varnish on the damping coils has burnt out;

- the processor is darkened.

If the board is in working order, then you can clean the contacts, since they often oxidize during operation, and this leads to reduced switching. As a result, the sensors often fail and the signal simply does not reach the processor. This leads to a program failure, and the drum drive simply does not receive a command to move.

Such work can be done on your own.

If the rotation stop is accompanied by a burning smell, the appearance of dark smoke and sparks - therefore, the engine has burned out, it must be replaced with a new one. However, sometimes the appearance of smoke indicates wear on the brushes - this problem is not so critical, and it can be completely corrected on your own.

To do this, you need to remove the rear panel of the CMA and the drive belt, carefully pull out the connector with the wire in order to completely de-energize the unit.For the convenience of diagnostics and further repairs, lay the SMA on one side - after that you can see the brushes, they are located in the upper part of the engine. They need to be removed and carefully examined: if scratches are visible on the surface, they can be cleaned with fine-grained sandpaper. Besides, be sure to measure the length of the element - if it has decreased by 1.5 cm or more, then the parts must be replaced.

Prevention methods in the future

In order to prevent problems associated with stopping the movement of the drum of the CMA, the recommendations of the experts should be adhered to.

Before loading dirty laundry into the washing machine, empty your pockets thoroughly - they should not contain small coins, rubber bands and other objects that could get stuck in the equipment.

Wash all women's bras, handkerchiefs and baby socks in special bags.

The connection of the CMA must be made only through an RCD or at least through an extension cord with a differential blocker, this is especially true if you live in an area with frequent power outages.

Pay particular attention to the accuracy of the grounding technique.

And, of course, from time to time to the technique you need to arrange preventive cleaning, which will save metal elements from the appearance of scale.

Obviously, in the case when the CMA drum began to rotate badly or stopped altogether, most often you can cope with the malfunction on your own. However, breakdowns of the control unit and electrics require a professional approach, since any attempt to repair the MCA may result in a deterioration in its technical condition.

For information on why the drum does not spin in the washing machine, see the next video.

The comment was sent successfully.