Washing machine cross: characteristics, causes of malfunctions and repair

The crosspiece is an important element of the washing machine that connects the tub and drum. If it is made of soft metal, it deforms over time, so it becomes necessary to replace or repair it. To do this, you need to know where it is and how to remove it correctly.

Characteristic

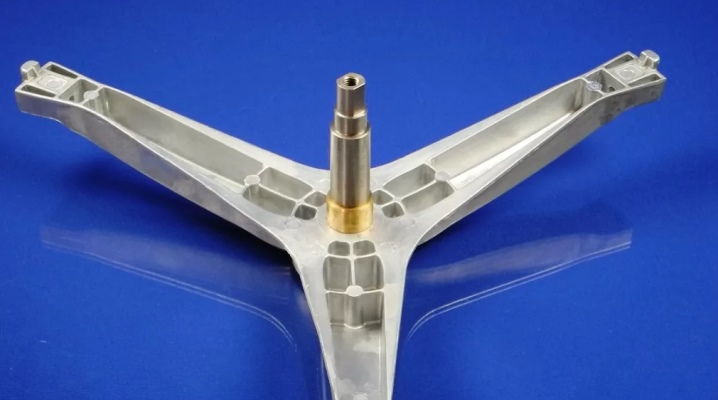

The cross of the washing machine is located between the drum and the tub. Such a detail provides the connection between these elements of the automatic machine. There are bearings inside the cross, so it is often sold complete with them, as well as with oil seals. The crosspiece is made from a durable but lightweight material such as stainless steel or aluminum alloy.

The crosses in washing machines of different brands are similar to each other, but still have certain differences. Therefore, if it is necessary to replace such a part, it is important to purchase a suitable element, taking into account both the manufacturer and the model of the automatic machine. The difference will be in the length of the shaft, the distance between the bearings, the size of the bearings and other characteristics.

There are also home-made crosspieces on sale for those machines for which such parts are not supplied.

Appointment

The main function of the cross is to ensure the operation of the moving part of the washing machine. A bearing assembly, which is attached to the crosspiece, is responsible for the rotation of the drum. It is this part that holds the drum itself, so damage to it can lead to serious damage.

Exploitation

To prevent damage to the crosspiece, it is important to be attentive to the sounds that occur during the washing process. In case of deformation of the part, the user will hear a creak and rattle... If, during the operation of the machine, there is a rustling, knocking or any other extraneous sound, this should also alert and cause the condition of the cross to be checked.

Both the restoration and replacement of such a part will not cost a large amount, but the repair work is rather complicated and painstaking, therefore, it is often necessary to contact a professional craftsman.

Causes of malfunctions

Failure of the crosspiece in most cases is associated with bearing wear. Such a breakdown, as a rule, is not abrupt, because it is preceded by the occurrence of noise and hum during washing, which indicates the wear of the bearings. If you ignore too noisy work and do not make a timely replacement, the cross will soon collapse.

Other causes of crosspiece problems:

- manufacturing defects;

- water of increased hardness;

- poorly executed repairs.

Defective crosspieces are usually made of poor quality alloy or with defects during production. This type of marriage is quite rare, but it still happens, as a result of which the part does not fulfill its function and quickly breaks down.

Too hard water can damage even the best quality crosspieces.... Due to the constant use of such a liquid, the drum moves with difficulty, which damages the bearings and as a result damages the driving element.

As for poorly carried out repairs, damage to the cross is possible if the bearings are inexpertly replaced.

Repair and replacement

If the cross is faulty, the best solution is to immediately contact the master. He will inspect the part and determine if repairs are required. If the bearings are worn out, only these elements need to be replaced.If the cross is damaged or burst, you will have to change it completely.

If you are going to repair the machine yourself, keep in mind that this is not such an easy task. If you have any doubts about the serviceability or your capabilities, be sure to consult a professional. The first step in the repair is to remove the tank. To get to it and remove the crosspiece from the drum, the machine is disassembled from the front or through the top, depending on its design.

First, the water supply is shut off and the machine is disconnected from the network. Next, you need to drain the water, remove the inlet hose and move the device away from the wall so that there is more room for work. After pulling out the stem and disassembling the wall of the machine, disconnect the engine, after which you can remove the tank. This is easy to do in case it is collapsible, since it is split into two separate parts.

With a non-separable tank, difficulties may arise at this stage, so it is unscrewed after cutting or replaced completely together with the cross.

After taking out the tank, inspect the bearings on the bushing and, if the breakage is caused by their wear, replace them. To remove such parts from the squashed shaft, you will have to make an effort, since they often sit quite tightly. In some cases, when the bearings are stuck to the shaft, you cannot do without a chisel... You can replace the oil seals at the same time. If the breakdown was in bad bearings, the repair is completed by assembling the machine in the reverse order.

If it is necessary to replace the crosspiece, it must be removed from the drum, that is, unscrew the bolts. After removing the worn or bent part, replace it with a new element, and then reassemble the washing machine and make sure that normal operation is restored.

If the repair is carried out on your own, then for proper assembly it is recommended to photograph all parts and elements of the device when you disassemble it.

For information on how to restore the crosspiece of the washing machine, see below.

The comment was sent successfully.