Washing machine motors: features, varieties, tips for choosing

When choosing a washing machine, buyers are guided not only by external parameters, but also by technical characteristics. The type of motor and its performance are of paramount importance. What engines are installed on modern "washing machines", which one is better and why - we have to analyze all these questions.

Device and principle of operation

The drum drive motor of the washing machine is usually fixed at the bottom of the structure. Only one type of motor is installed directly on the drum. The power unit rotates the drum, converting electricity into mechanical energy.

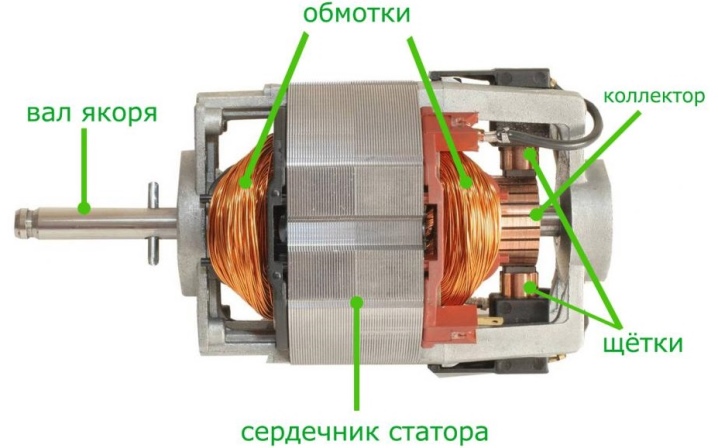

Let's consider the principle of operation of this device using the example of a collector motor, which at this moment is the most common.

- The collector is a copper drum, the structure of which is divided into even rows or sections by insulating “baffles”. The contacts of the sections with external electrical circuits are located diametrically.

- The brushes, which act as sliding contacts, relate to the conclusions. With their help, the rotor interacts with the motor. When a section is energized, a magnetic field is generated in the coil.

- Direct engagement of the stator and rotor forces the magnetic field to rotate the motor shaft clockwise. At the same time, the brushes move through the sections, and the movement continues. This process will not be interrupted as long as voltage is applied to the motor.

- To change the direction of movement of the shaft on the rotor, the distribution of charges must change. The brushes are turned on in the opposite direction thanks to electromagnetic starters or power relays.

Types and their characteristics

All motors found in modern automatic washing machines are divided into three types.

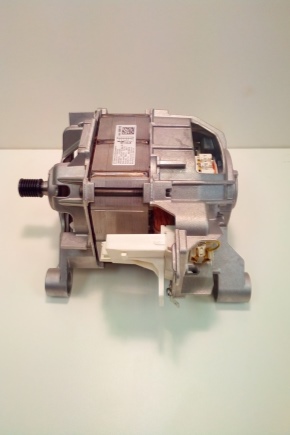

Collector

This motor is the most common one today. Most of the "washing machines" are equipped with this particular device.

The design of the collector motor consists of the following elements:

- body made of aluminum;

- rotor, tachometer;

- stator;

- a pair of brushes.

Brush motors can have a different number of pins: 4, 5 and even 8. The brush design is necessary to create contact between the rotor and the motor. Collector power units are located at the bottom of the washing machine. A belt is used to connect the motor and drum pulley.

The presence of a belt and brushes is a disadvantage of such structures, since they are subject to severe wear and due to their breakdowns, there is a need for repair.

Brush motors aren't as bad as they might seem. They are also characterized by positive parameters:

- stable operation from direct and alternating current;

- small size;

- simple repair;

- clear diagram of the electric motor.

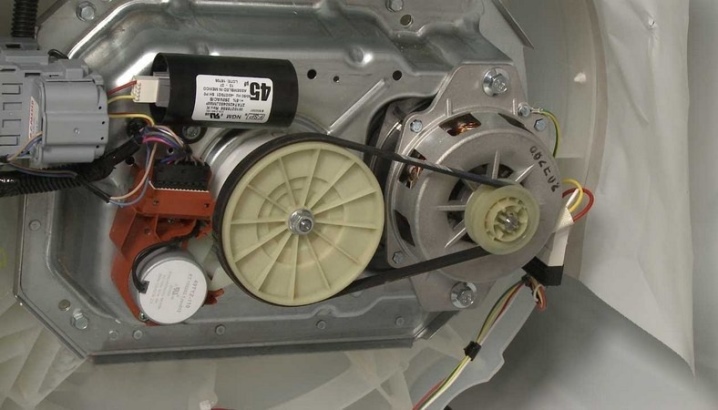

Inverter

This type of motor first appeared in "washers" only in 2005. This development belongs to LG, which for several years held its position as a leader in the world market. Then this innovation was used in models from Samsung and Whirlpool, Bosch, AEG and Haier.

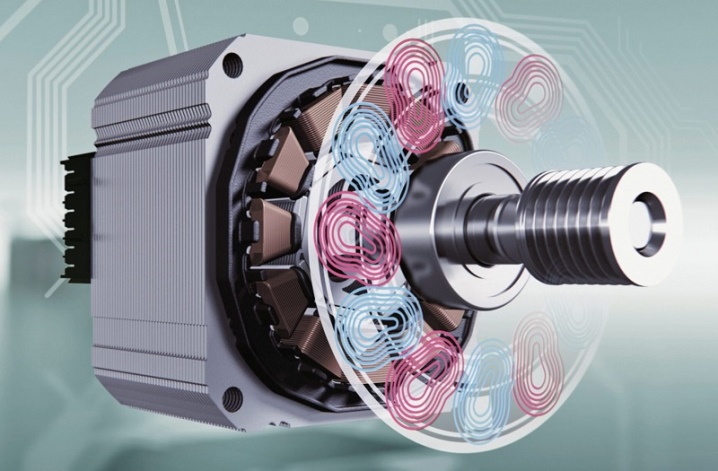

Inverter motors are built directly into the drum... Their design consists of a rotor (permanent magnet cover) and a sleeve with coils called a stator. The brushless inverter motor is distinguished by the absence of not only brushes, but also a transmission belt.

The anchor is assembled with magnets. During operation, the voltage is applied to the stator windings, having undergone a preliminary transformation into an inverter form.

These features allow you to control and change the speed of revolutions.

Inverter power units have many advantages:

- simplicity and compactness;

- economical consumption of electricity;

- very low noise production;

- long service life due to the absence of brushes, belt and other wear parts;

- reduced vibration during spinning even at high rpm selectable for work.

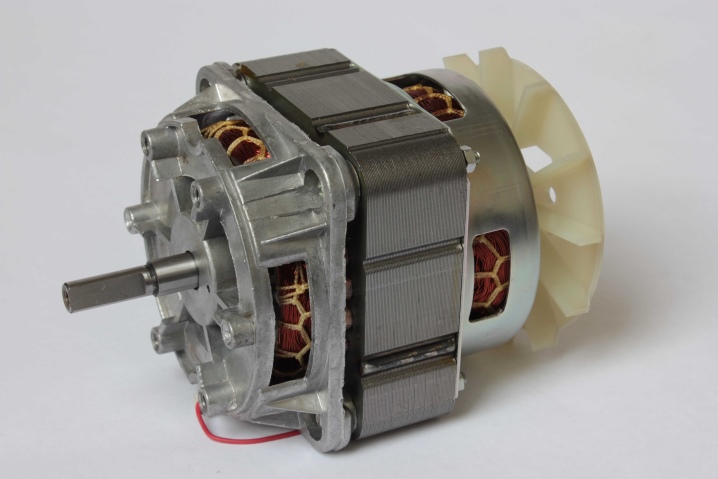

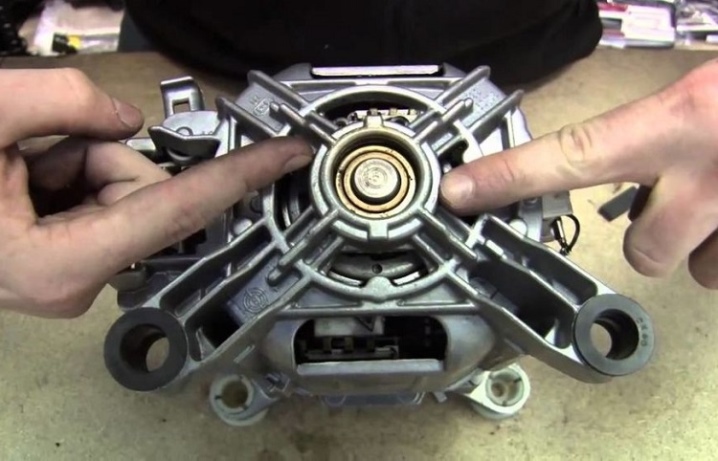

Asynchronous

This motor can be two- and three-phase. Two-phase motors are no longer used, since they have long been discontinued. Three-phase asynchronous motors still work on early models from Bosch and Candy, Miele and Ardo. This power unit is installed at the bottom, connected to the drum by means of a belt.

The structure consists of a rotor and a stationary stator. The belt is responsible for the transmission of torque.

The advantages of induction motors are as follows:

- easy maintenance;

- quiet work;

- affordable price;

- quick and straightforward repair.

The essence of the care is to replace the bearings and renew the lubricant on the motor. The disadvantages include the following points:

- low power level;

- the probability of a weakening of the torque at any moment;

- complex control of electrical circuits.

We found out what kind of washing machine engines are, but the question of choosing the best option still remained open.

Which to choose?

At first glance, it may seem that the advantages of an inverter motor are greater, and they are more significant. But let's not rush to conclusions and think a little.

- In terms of energy efficiency, inverter motors are in first place... In the process, they do not have to cope with the frictional force. True, these savings are not so significant as to be taken as a full-fledged and significant advantage.

- In terms of noise level, inverter power units are also at a height... But you need to take into account the fact that the main noise occurs during spinning and from draining / collecting water. If in brushed motors the noise is associated with the friction of the brushes, then a thin squeak will be heard in universal inverter motors.

- In inverter systems, the speed of the automatic machine can reach up to 2000 per minute.... The figure is impressive, but does it make sense? After all, not every material can withstand such loads, so such a rotation speed is actually useless.

More than 1000 revolutions is all superfluous, because things are squeezed out perfectly even at this speed.

It is difficult to unequivocally answer which motor for a washing machine will be better. As can be seen from our conclusions, the high power of the electric motor and its overestimated characteristics are not always relevant.

If the budget for the purchase of a washing machine is limited and driven into a narrow framework, then you can safely choose a model with a collector motor. With a wider budget, it makes sense to buy an expensive, quiet and reliable inverter washing machine.

If a motor is chosen for an existing car, then first of all you need to carefully study the issue of the compatibility of power units.

Every detail and characteristic must be taken into account here.

How to check if it works?

There are collector and inverter motors on sale, so further we will talk only about these two varieties.

It is quite difficult to check the performance of a direct drive or inverter motor at home without the involvement of specialists.The simplest way would be to activate self-diagnostics, as a result of which the system itself will detect the malfunction and notify the user by highlighting the corresponding code on the display.

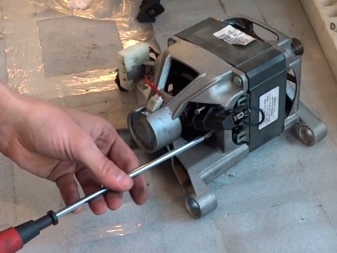

If, nevertheless, it becomes necessary to dismantle and check the engine, then these actions must be performed correctly:

- de-energize the "washer" and remove the back cover by unscrewing the fasteners for this;

- under the rotor, you can see the screws holding the wiring, which also need to be removed;

- remove the central bolt securing the rotor;

- dismantle the rotor and stator assembly;

- remove the wiring connectors from the stator.

This completes the disassembly, you can proceed to inspect and test the performance of the power unit.

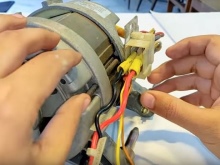

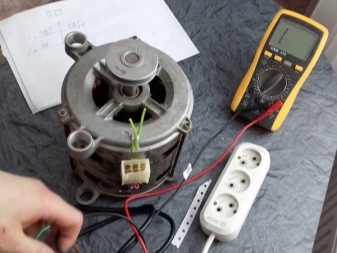

With brushed motors, things are easier. There are several ways to check their work, but in any case, you must first dismantle it. To do this, you will need to perform a number of actions:

- turn off the power to the machine, remove the back cover;

- we disconnect the wires from the motor, remove the fasteners and take out the power unit;

- we connect the winding wires from the stator and rotor;

- we connect the winding to the 220 V network;

- rotation of the rotor will indicate the health of the device.

Operating tips

With careful and proper handling, the washing machine can last much longer and require less repair. For this you need to adhere to a few simple rules.

- When connecting, you need to carefully select the wires in terms of power, brand and section. Two-core aluminum cables cannot be used, but copper, three-core cables can.

- For protection, you must use a circuit breaker with a rated current of 16 A.

- Earthing is not always available in homes, so you need to take care of it yourself. To do this, you will need to separate the PEN conductor and install a grounded socket. It is better to choose a model with ceramic fittings and a high class of protection, especially if the "washing machine" is in the bathroom.

- Do not use tees, adapters and extension cords in the connection.

- With frequent voltage drops, it is necessary to connect the washing machine through a special converter. A good option is an RCD with parameters no higher than 30 mA. The ideal solution would be to organize meals from a separate group.

- Children should not be allowed near the toy car with buttons on the control panel.

Do not change the program during washing.

Features of engine repair

Inverter motors at home cannot be repaired. To repair them, you need to use a complex, professional technique. And here the collector motor can be brought back to life with your own hands.

To do this, you first need to check every part of the motor to identify the true cause of the malfunction.

- Electric brushes located on the sides of the body. They are made from a soft material that wears off over time. The brushes need to be taken out and visually assessed their condition. And you can also connect the motor to the network - if it sparks, then the problem is definitely with the brushes.

- Lamels with the participation of brushes, they transfer electricity to the rotor. The lamellas sit on glue, which, when the engine is jammed, can lag behind the surface. Small detachments are removed with a lathe - you only need to grind the collectors. The shavings are removed by processing the part with fine sandpaper.

- Disturbances in the rotor and stator windings affect the power of the motor or even cause it to stop. To check the windings on the rotor, a multimeter is used in resistance test mode. The multimeter probes must be applied to the lamellae and the readings must be checked, which in a normal state should be in the range from 20 to 200 ohms. A lower resistance will indicate a short circuit, and with high rates, we can talk about a winding break.

You can also check the stator winding with a multimeter, but already in buzzer mode. The probes must be applied alternately to the ends of the wiring. In normal state, the multimeter will be silent.

It is almost impossible to restore the winding; with such a breakdown, a new motor is bought.

You can find out which motor is better, or what is the difference in the motors of washing machines, below.

The comment was sent successfully.