Washing machine tacho sensor: features, malfunctions and their elimination

An automatic washing machine is a rather complex device that consists of many units and parts, including electromechanical ones. If the machine breaks down, it is not always necessary to take it to a service center, some breakdowns can be eliminated on their own - for example, a tachometer.

What it is?

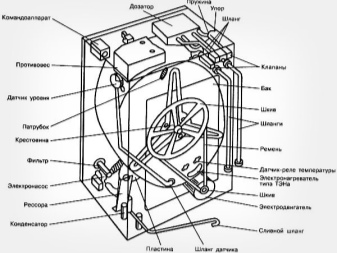

Any washing machine works thanks to an electric motor, whose function is controlled by the so-called tachogenerator - a small electrical appliance. The washing machine's tachometer is located on a part of the engine called the rotor. The sensor serves to monitor the engine speed and takes into account the voltage generated by the electric current. Due to the fact that the washing machine has such a sensor, all units (including the engine) operate in the parameters specified by the washing program.

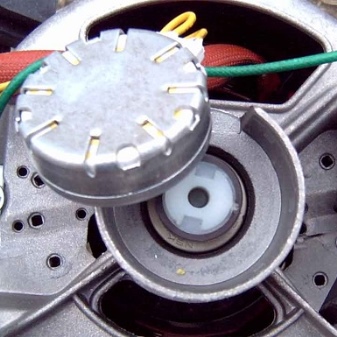

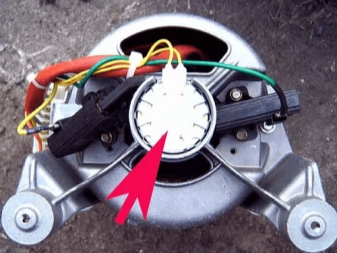

In appearance The tachometer looks like a compact metal ring equipped with small diameter wires. The tachogenerator can be easily found in automatic washing machines, equipped with a collector type of the engine.

Determining which version of the engine is used on your model of an automatic washing machine will not be difficult - you will need to dismantle the back panel of the case, and if you see a large wheel with a drive belt, you will see a collector motor.

In the event that upon inspection you do not find a pulley with a drive, it should be understood that your machine operates on an inverter type motor, where the sensor is built into the housing. The tachometer registers the speed of the electric motor, and transmits the received data to the electronic board of the central control unit.

The data is processed and the washing machine either ramps up or down.

Breakage signs

In the event that the tachogenerator fails, the normal operation of the entire washing machine is disrupted. The reason for this is the lack of data from the control unit and the rotation speed of the electric motor. The breakdown manifests itself as follows:

- if the electric motor of the washing machine is gaining an excessive number of revolutions, then during the operation of the unit, you can feel an increased level of vibration, noise, beating inside the case;

- with an increased load on the electric motor, the pulley bearing mechanism and shock absorbers of the washing machine experience excessive load and may fail prematurely;

- at uncontrolled revolutions of the electric motor, the entire system of mechanisms is unbalanced, due to which we hear the beating inside the machine body, while the pulley drive belt quickly wears out or breaks;

- in washing machines with an inverter motor, if the tachogenerator breaks down, a sound similar to a beeping will be heard, while the rotation of the drum, as a rule, is blocked, and the sound increases;

- if the tacho sensor breaks down, the washing machine may run in jerks and not carry out the spin program.

In the event of a malfunction of the tacho sensor, the control unit of the washing machine stops the operation of the unit and displays an alarm message in the form of a breakdown code on the display. Each brand of washing machine may have its own code and differ from other machines.

How to check?

The tachogenerator is checked by measuring its resistance, why use the device with a multimeter.

- The device will need to be set in the ringing mode and brought to the tachogenerator terminals... Then, with your free hand, you need to set the rotor of the motor in rotational motion - the direction of rotation can be any. If at the moment of rotation the multimeter reproduces short sounds or the arrow oscillates, it means that the tachometer is working properly.

- The device must be switched to the voltage detection mode, setting the limit to 4-5 Volts, and bring it to the terminals of the tachometer. We rotate the rotor and observe the device. If the voltage generation is 0.2-2 Volts, it means that the tachometer is working properly.

In the case when the diagnostics with the help of a multimeter did not give any results, it is necessary to visually inspect the tachometer - how securely it is attached to the electric motor. If the fastening bolt is loose, it must be tightened. Sometimes the tachometer's contacts may come off - they are also checked and tightened. The tachogenerator in good condition on the multimeter shows a current resistance of 60 ohms. If the tachometer does not show activity during the diagnostics by the device, then it must be replaced.

How to replace?

Replacement of the tachogenerator can be done after disconnecting its connectors and removing it from the attachment point. The connectors are easy to detach, and you'll burn them in the common column of connectors on the motor. To dismantle the tachometer, you will need a thin-diameter screwdriver. After disconnecting the connectors, it is necessary to remove the top cover of the tachometer - it can be unsecured and simply held on to the latches, or it is held by small bolts (in different models of washing machines, the sensors are arranged in their own way).

Then the tachometer is replaced with a new part and its connections are assembled in the reverse order. In order not to get confused and not make mistakes, experts advise filming the dismantling process with a phone camera, and then, guided by the pictures, connect a new tachometer.

After the installation is completed, the serviceability of the connections and the tachometer is checked with a multimeter.

How to check the tachometer of the washing machine, see the next video.

Clearly and concisely, thank you!

The comment was sent successfully.