Washing machine pump repair: signs of malfunctions, problem solving, expert advice

In automatic washing machines from various manufacturers, water is pumped into the tank and drained into the sewer by means of a pump. This node is one of the most important. When the pump fails, the corresponding error code appears on the screen. To fix the breakdown, you can use the help of professionals. However, if you wish, you can repair the pump in the washing unit yourself, following simple instructions.

Breakage signs

If, during the operation of the washing machine, malfunctions with a drain are noticed, then the cause should be found. In this case, the pump fails or the drain system is clogged with dirt. The malfunction can be determined if the pumping system does not turn on in the water drain mode. The same problems exist if a humming sound is heard when draining or the machine makes too much noise. Of course, water from the waste fluid drain hose does not flow or flows out too slowly.

In addition, the washing machine may switch off during draining. Often there are cases when the pump motor is running, but water does not flow.

The listed signs can appear both individually and several at once. Many of them indicate pump malfunctions. Before dealing with the pump itself, other breakdowns should be excluded.

To do this, you need to check the drain hose and filter. If there is debris, they must be cleaned. If they turn out to be clean, then they disconnect and take out the pump, disassemble, clean or change it.

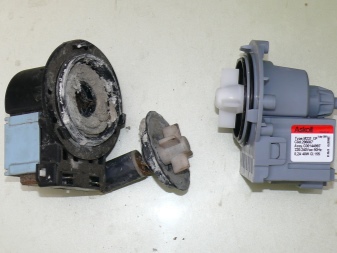

Most often, the pump does not work if the motor bushings are badly worn out. And also a short circuit of the motor and a break in its winding lead to this. A broken or blocked impeller can provoke a pump failure. Often, the latter causes the washing device to leak.

Besides, the pump may not pump if it is incorrectly connected or the water level sensor is faulty. In this case, the pump will work constantly. Filter clogs often lead to pump breakdown, as well as the ingress of a foreign object.

Foreign matter can destroy the impeller. In these cases, hooting sounds will be heard when the pump is running.

Where is the pump located?

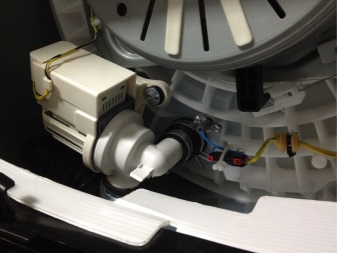

The location of the pump differs depending on the model of the washing machine. In some, to get a broken pump, just open the bottom panel. In other models, you will have to disassemble the unit almost completely before you can get to the faulty mechanism.

For example, in models of washing machines LG, Candy, Beko, Whirpool, Ariston the pump is located at the bottom. You can get it by laying the device on its side and removing the bottom panel. After that, it is enough to unscrew the screws on the volute with the filter to see the pump.

In washing household appliances from Zanussi and Electrolux, the pump is located behind the back cover. This allows you to get to her pretty quickly. It is enough to unfold the unit and unscrew the screws holding the back panel.

The most difficult in terms of pump availability are washing machines from Siemens, Bosch and AEG. They will have to completely disassemble the front of the device and the control panel.

How to disassemble the pump?

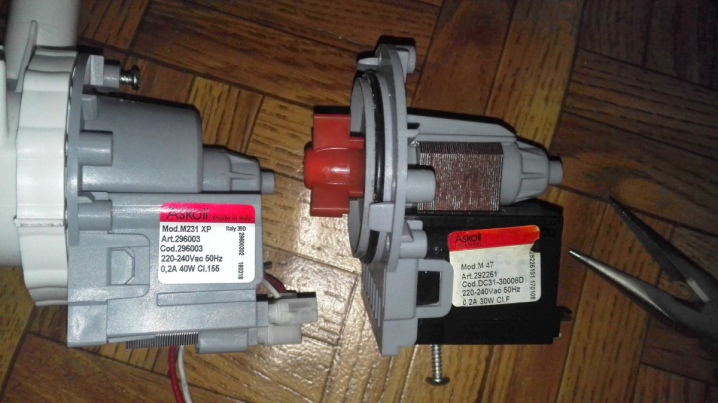

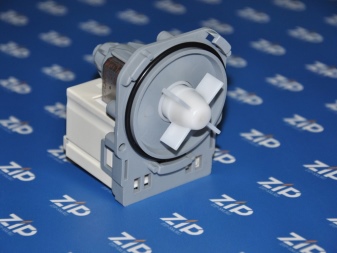

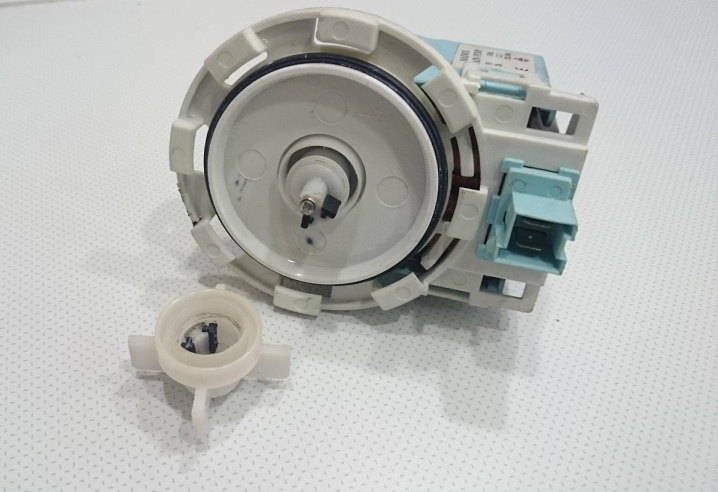

Removing the pump and disassembling it is quite simple, especially if you know what type it belongs to.Modern models are divided into circulation and drain. The pump device includes a motor, an impeller and a plastic pipe.

Disassembly begins with the fact that the washing unit is disconnected from the mains. Then it is necessary drain the water from the tank. This is important if the pump breaks down directly during the wash.

It is not difficult to dismantle the pump yourself; it is enough to follow certain recommendations.

- First, the hose is disconnected to the liquid outlet.

- Then you need to open the door of the technical hatch and take out the filter.

- Then place the washing unit on the left side so that the lower part can be easily accessed.

- Next, the protective cover is removed at the bottom of the device. This is best done with a sharp knife. The cover is attached to the upper and lower latches, which must be pry off with a knife. It is necessary to remove the cover carefully so that the mounting holes are not damaged.

- Bolts will be visible under the cover, which must be unscrewed.

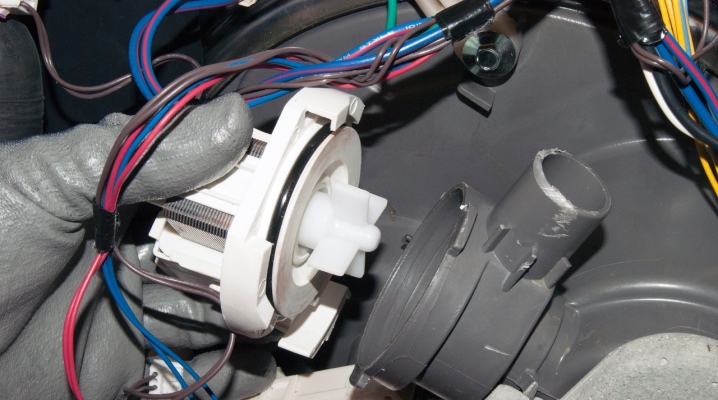

- You can now disconnect the pump from the power leads. The pump is removed from the snail with screws or by slightly turning it counterclockwise.

- Before removing the pump from its place, it is important to take a photo so that there are no mistakes during installation.

In some models of devices, the motors seem to be non-separable. However, they can also be removed using a building hair dryer with a low heating temperature. Warm up the shank, and then pry the cross with a screwdriver and carefully remove it from the body. After removing the pump, it is necessary to thoroughly clean it from plaque and dirt.

How to carry out repairs?

When repairing a drain pump with your own hands, it is important first of all to inspect the impeller. It must be in the correct position on the axis. For example, splines, which are fasteners, can break off on it. As a result, the impeller leaves its place. In the simplest case, it is enough to simply fix the impeller in the same place.

It is necessary to rotate the impeller with your fingers to check the correctness and smoothness of its movement. In case of tight scrolling or converging it off the axis, it is necessary to replace the part with a new one.

Also it is important to inspect the electrical part of the pump, while paying special attention to the integrity of the winding coils. After all, they are responsible for bringing the pump rotor into operation.

Malfunctions are indicated by the presence of burning on the coils or by a visible break in the copper wire. This unit is best replaced as a whole, since partial repairs will not give the desired effect.

The place of connection of the terminal in the contact group also needs careful inspection. In this district the formation of an oxide film is possible. With such a malfunction, it is enough to simply make cleaning contacts.

Worn bearings can cause run-out, which causes the impeller to rub against the volute casing. As a result, the pump is too loud and does not work well. Sometimes even its complete stop is possible. This breakdown can be easily removed, by replacing the ball bearings. You can buy them in special stores or service centers.

The electrical circuit of the pump motor also needs to be checked. It should be ringed with a voltmeter to detect an open contact. Such a breakdown will be understood by the lack of readings on the device.

Sometimes the problem is in a worn out gasket. This becomes noticeable from water leaks. It will be possible to eliminate such a moment by installing a new sealing element.

When temporarily eliminating impeller noise due to lack of replacement parts you can try to trim the blades. This should be done with a sharp knife, and the cut should not exceed 2 millimeters. Moreover, it is better to cut a little less. Otherwise, the performance of the unit will decrease.

A pump can be considered repaired if it has been cleaned and all parts that have failed have been replaced.At the end, you can install the housing with the blades in place and fix it with latches. Observing safety rules, it is necessary to connect the voltage to the contacts of the device, and then check its operation. If everything is working normally, then you should connect the volute and completely return all parts of the pump to the body of the washing equipment.

Expert advice

There are a number of recommendations from specialists, adhering to which, you can avoid pump damage and extend the life of the washing unit. The most important thing is to check the pockets of your clothes before washing. After all, various foreign objects, especially metal ones, can cause significant damage to the device.

And you should also properly take care of household appliances. Often, the pump fails due to the fact that debris and various small parts enter the machine's drain system. The pump does not tolerate washing things on which a large amount of dirt has adhered. Mechanical impact can cause significant damage to the pump.

To prevent breakdowns, experts recommend pre-install a cleaning filter on the water intake. The correct action is to shake up and thoroughly inspect things before each wash. In the event that the clothes have significant contamination, it is best to pre-soak them.

If the clothes have buckles or rivets, then such things should be turned inside out... Do not forget to use special washing bags.

Limescale can cause multiple breakdowns. To avoid this, it is enough to add special substances during washing, which will prevent the formation of limescale.

Repair of the washing machine pump is presented below.

The comment was sent successfully.