Why doesn't the washing machine spin and how to fix the problem?

In the modern world there are so many important and interesting activities that you do not want to waste time washing. To everyone's joy, there have long been automatic washing machines that handle this duty without any problems. But still, sometimes even reliable equipment fails. It is a complete surprise when the machine does not spin during the working cycle. There is no need to rush to do her job manually. It's better to figure out what could have caused the program to crash.

Description of the problem

The fact that the machine does not spin is indicated not only by the fact that the technique stops during the intended spin, does not gain high speed, and the program suddenly freezes. You can find out about the problem if there is water in the drum at the end of the wash or on wet items after the spin phase. The fact that the washing machine does not accelerate when it goes to spin can be affected by various malfunctions. Before calling the wizard from the service, you should try to deal with the problem yourself.

If the problem is that the washing machine hums and stops spinning after the washing phase, it is possible that the function that determines the strength of the oscillations at the speed of the washing drum is to blame. When these fluctuations become more than the allowable norm, the washing machine stops and does not spin. This is how the vending machine reacts to a dangerous amplitude of tank movement. Strong shaking may begin due to worn shock absorbers, uneven surface on which the washing machine stands.

Any atypical sounds during the operation of the equipment are a signal that it needs to be examined.

The most commonplace reasons for the appearance of noise lie in the blockage of the space between the tank and the drum... Often there are small extraneous objects: coins, accessories, etc. Blockages are often an obstacle to the proper operation of your washing machine. She squeezes badly and does not build momentum. So that the machine does not hang up again and more serious breakdowns do not occur, it is necessary to remove the heating element and get the things that have fallen into it.

Squeaks can also appear due to bearing wear or belt abrasion. In this case, you have to disassemble the case and check the integrity of the components. If something is broken, you will have to change the spare part.

Possible violations of operating rules

Sometimes the reason for washing without spinning can be caused by banal carelessness.

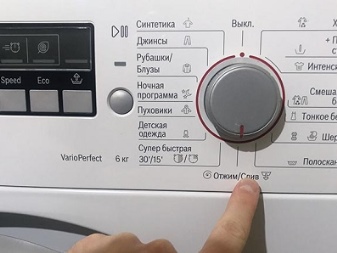

Wash program selected incorrectly

In this situation, the spinning does not work in the appliance. But rushing to twist wet things with your hands is not an option. It is better to read the instructions carefully. Not every wash program has a spin function. Sometimes the laundry spins out at a low drum speed, or the wash cycle ends with a rinse. Then the water is drained from the car, but the things inside remain wet. If, after opening the hatch door, water is detected in the tank, you need to check how the program options are set. Perhaps spinning is not expected initially. For example, if a gentle mode is selected for things made from delicate types of fabrics, and so on. The problem is not that, since everything will be fixed by resetting the regulator to the desired function.

But it also happens that the spin is simply accidentally turned off by one of the household members.To squeeze out the washed things in this case, you just need to reset the regulator to the "Spin" option, and start the process with the "Start" button. The number of revolutions on the regulator is not set - also one of the banal reasons for a non-accidental spin. At the zero mark, the machine does not provide for spinning the laundry. The water will simply drain and the cycle will end.

Uneven distribution of laundry

This is what upsets the balance of the washing machine. Models with a display will report a balancing problem with the information code UE or E4. In other devices, the washing process simply stops at the spin stage, and all indicators light up at the same time. Often, if an imbalance occurs, the laundry in the drum becomes lumpy. And also the incorrect loading of bedding leads to a crash in the program. For example, when they were stacked in a tank. To eliminate the imbalance, it is enough to manually distribute the laundry evenly.

In some machines, imbalance control is installed, and such situations are excluded. At the same time, spinning occurs with less vibration and decibels. This has a beneficial effect on the equipment, extending its service life.

Drum overload

Eliminating weight overload is the easiest thing to do. You just have to remove some of the laundry from the washing machine. Or try to redistribute things, and restart the "Spin" function. Exceeding the maximum permissible weight poses a danger to the device, therefore, in case of such a violation, an error code is displayed on the display or the whole process is stopped. The situation can be easily solved by turning off the power and removing some of the items from the washing tub. To prevent drum overload in the future, load the laundry according to the instructions for use... It is important to take into account the fact that wet clothes become heavier, therefore maximum load is undesirable.

Imbalance and overloading are equally unsafe for washing machines. Automation stops work before the start of the most active phase of washing - spinning at high speeds.

Malfunctions in different areas of the device and how to fix them

If an automatic or semi-automatic machine washes, and the drum is stationary during spinning, the problem is not in setting the programs. Probably, some components were damaged. There is no need to immediately take home appliances for repairs. First, you can try to solve the problem on your own.

Drain pump

If, after washing, the things in the tub remain not just wet, but floating in the water, most likely something is wrong with the drain system. Presumably, the drain filter, the pipe or the hose itself can be clogged. In addition, a breakdown of components or a pump may occur. The easiest way to remove clogging is in the drain filter (cleaning is necessary regularly as a preventive measure). To cleanse first you need to remove the unscrewed laundry and drain the water from the tank. All manipulations are carried out with the machine disconnected from the network. The water is drained through an emergency hose located behind the panel at the bottom of the case.

It is more difficult to cope with the inspection of the drain hose for a blockage... It will be even more difficult to disassemble the washing machine. for cleaning the branch pipe. Replace directly pump can only be performed by a specialist with experience.

In addition to the above reasons, the machine does not spin the drum if it is clogged or if the drain pump is broken. Water that does not find its way into the sewer will prevent the system from starting the program at the required speed. If the equipment has not drained the water, then you should not expect rinsing followed by spinning. First of all, you need to check the pump filter, thoroughly clean it, and if this measure did not help, continue to determine the malfunction.

The most common reason for the lack of drainage is a blockage in the pump itself. After removing the pump filter, you can see the cross-shaped blades inside, you need to scroll them with your finger - if they do not rotate, then something is stuck inside.It is recommended to inspect the pump and remove the blockage inside it.

Often, a clogged pump will permanently fail. The increased load can lead to combustion of the pump winding, breakage of its blades. In these variants, the pump replacement cannot be avoided.

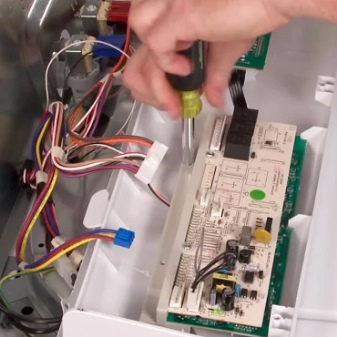

Electronic module

This is the most serious malfunction in an electric washing machine. The part will have to be stitched or replaced with a similar new one. The electronic module starts the work of all programs, receiving signals from the sensors. If it was not possible to identify any of the above reasons for the failure of the spin function, most likely the problem lies precisely in the module. It is problematic to repair the module on your own. It is better to entrust specialists to flash and change the board.

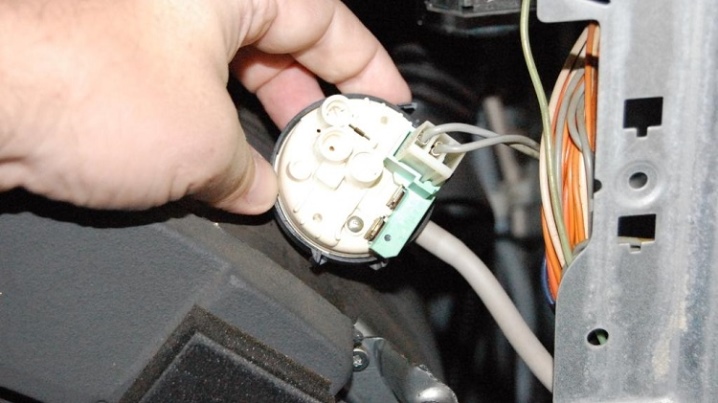

Pressostat

A malfunction in this sensor will cause the spin to stop. If the system does not receive a message from the pressure switch about the presence or absence of water in the tank, the "Spin" command is not executed.

This element cannot be restored; it will have to be changed. But without having the technical knowledge of the design and skills of repairing washing machines, it is better to contact the service.

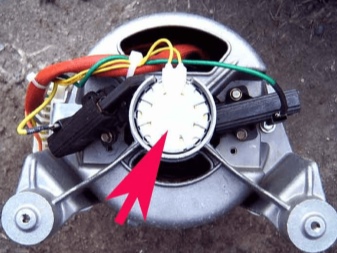

Tachometer

A sensor for counting drum revolutions in 1 minute is installed on the motor shaft. When this element breaks, the automatic system does not pick up the corresponding signal, and the speed level remains unchanged. In this case, the machine does not have the ability to spin the laundry.

To the delight of users, this problem rarely appears. First of all, you need to check the status of the contacts. If the connection is loose, the user can handle the repair themselves. But when the contacts are in order, most likely, the matter is in the breakdown of the tachometer, and it will have to be replaced.

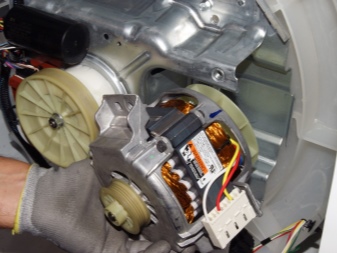

Engine

When an engine breakdown occurs just before spinning the laundry, first you need to make sure that the winding is intact. You will need a tester for this. If some circuit does not "answer" in the dial mode, then the circuit is open, and it is necessary to find out where the break is. If there is an old induction motor, check two windings - washing and wringing. When the spinning winding burns out, the washing machine will be able to carry out the wash cycle only without spinning. We'll have to change the engine so as not to squeeze out manually.

Individual elements in the engine can also fail. The most common malfunction is considered to be the breakdown of the brushes. These components are installed on collector motors as moving contacts. From friction, over time, the brushes are erased, the contact is broken, and the engine stops.

Since the standard spin is usually carried out at maximum speed, a failed motor is not able to do this task. Therefore, it is during the final phase of washing that the first symptoms of breakage appear.

Only a professional can determine the specific cause of the breakdown and decide how to eliminate it. This requires removing the housing and the engine, checking its elements for operability. Sometimes the necessary tools are not available to the user, which means that it is not possible to unscrew the bolts and fasteners. Masters are unfamiliar with such a problem. Calling a specialist is often a real saving of nerves, time and money. Defective parts are often repaired or replaced with new ones. It may be necessary to change the motor itself.

Heating element

The task of the heating element is to provide the required temperature during the washing process. When malfunctions occur in the operation of the heating element, the electronic module receives a signal to exclude the spin mode. It is necessary to check the heating element on other programs. It will not hurt to inspect the part, perhaps a lot of scale has accumulated on it, or there is damage.

Other options

The new generation washing machines have one control board for all processes in the appliance. Often, equipment stops spinning the laundry precisely because of damaged elements on the board.In this case, these are those that are responsible for the spinning process and the functioning of the engine as a whole.

Checking the control board should be identical to checking the control module. Before removing the board, it is advisable to photograph its location, so that later it would be easier to restore everything as it was. After disconnecting the board, you need to open the protective cover on it. With a close examination of each element for swelling, burnout and any damage, the situation should become clear.

But if visually everything is whole, it is better to seek advice from specialists.

Useful Tips

To avoid problems with the washing machine, you need to operate it according to the instructions and follow simple recommendations.

- Use high-quality detergents for washing in the proportions indicated by the manufacturers... Saving or being generous with powders and gels is equally detrimental to the wash result and the function of the appliance. An abundance of washing powder will spoil the pressure switch someday.

- Use reliable surge protectors to protect the washing machine from power surges.

- Keep the machine clean inside and out. Clean filter, rubber seal and powder container regularly.

Before washing be sure to check your pockets for forgotten small items. Cigarettes, tokens, lighters and other small things that get inside can not only ruin things, but also harm the washing machine.

The user can actually cope with many problems on his own with adequate use of the device in accordance with the attached instructions. But if this does not solve the problem, it is probably time to call for help in the person of a competent foreman. Replacement of sensors, electric motor, control module should be carried out only by a specialist. You should not put yourself and your equipment at risk in an effort to save money on repairs. Buying a new washing machine will cost more than having it repaired professionally.

For information on why the Indesit washing machine does not spin and how to solve the problem, see the next video.

The comment was sent successfully.