Samsung washing machine belt: characteristics, operation and replacement

The belt in the washing machine is an important part of it, which ensures the rotation of the drum due to the fact that it connects it to the engine of the machine. However, due to the fact that this part is subjected to heavy loads, especially during spinning, it often fails. Replacing a belt in a Samsung typewriter is a repair of medium complexity, and you can cope with it even without contacting a specialist.

Characteristic

If you look into a brand new washing machine and pay attention to the drive belt, you will notice that it has medium tension. If we loosen it, then it will often slip along the pulleys of the electric motor and drum, which means that the effective torque coefficient will decrease. If, on the contrary, the belt tension is increased, for example, by buying a shorter replacement for it, then, of course, the efficiency will increase., however, its lifespan will drop sharply due to overload.

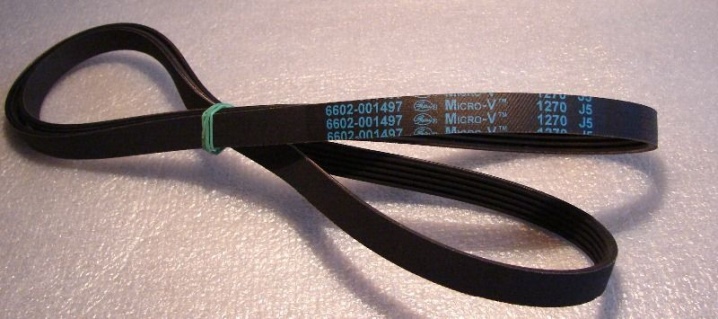

Each belt in Samsung washing machines is labeled. It consists of 4 numbers and one Latin letter, for example, 1234G.

Density is also an important parameter. There are only two types of belts on this basis - elastic and rigid. The former are more suitable for new washing machines. They stretch well, thereby enhancing the grip between the tank and the engine. But they cannot adjust the degree of tension.

Rigid belts for washing machines almost do not stretch, because of which, when installing them, you will have to change the position of the motor. However, it is impossible to do this on new machines, which means that this type of belts is suitable exclusively for old equipment.

They make belts for washing machines from polyurethane or rubber. Rubber belts are much stronger than polyurethane belts, but the latter provide a much higher coefficient of elongation. In addition, they are easy to install and remove. But in terms of service life, they are significantly inferior to rubber belts.

There are H- and J-belts. They differ in shape.

You can determine if an H- or J-shaped belt is installed on your machine by looking at the special grooves for it on the motor pulley.

In addition to all this, all Samsung car belts can be divided into two types.

- Wedge. They are used for those machines in which there is an asynchronous motor. In cross section, the strap is a trapezoid. These belts are quite elastic yet strong due to their tightness. For machines of foreign production, belts with a section of 3L are used, and for those produced in Russia, with sections A and Z.

- V-ribbed. Such belts are suitable for machines with a collector type of motor. Wedges can be seen in the cross section of this belt. Usually their number varies from 3 to 9. These belts are distinguished by their durability, flexibility and high useful rotation.

Appointment

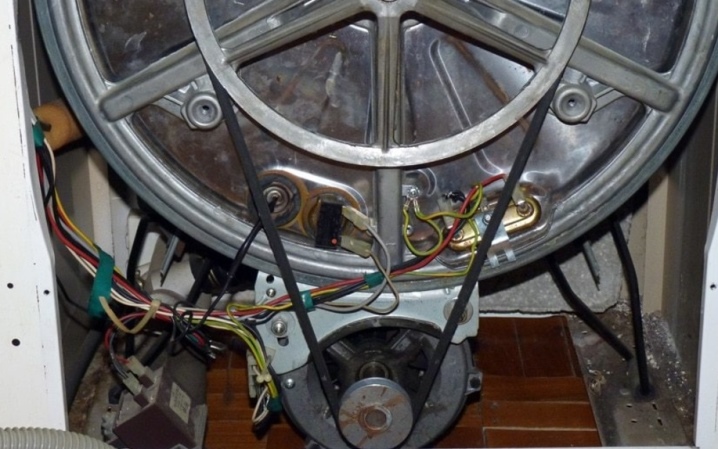

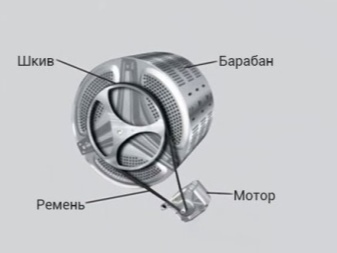

To drive the washing machine, the belt is the part thanks to which the equipment can perform one of its main functions - to rotate the drum. It is stretched between the rotating part of the electric motor and the drum axis, connecting them into one chain.

When the motor starts to rotate during washing, the belt moves along with it, and therefore the drum. And the belt also slows down the rotation of the drum if such a command is received from the control board, for example, at the end of the spin phase.

Exploitation

After the start of the wash cycle, the washing machine motor receives a command to start rotating at a certain speed in one direction or another. The belt transfers this engine torque to the drum, which causes it to rotate. It is no secret that enormous tension is exerted on the belt at this time.

Friction during starting, stopping or changing direction of movement, constant tension - all this reduces the service life of the spare part to 5-6 years. And with frequent or incorrect (constant overload) operation, this period is reduced even more.

Causes and types of malfunctions

If the drive belt in your washing machine comes off for the first time, it does not necessarily mean that it is defective. Perhaps you've just overloaded the machine and it can't handle that much friction. In this case, there is no need to change it.

But if a problem with it occurs regularly, this may be a signal to start repairs. Drive belt malfunctions can occur in several cases.

- The owner constantly overloads the tank. This is the most common cause of belt breakage in a washing machine. Even if the manufacturer declares the maximum weight of laundry to be 5 kg, this does not mean that the machine is capable of constantly working with such a load. As a result of such careless operation, the belt often flies and quickly stretches.

- Drum pulley breakage. The pulley is a fairly large wheel that sits behind the drum. Despite its simplicity, it is the weakest link in the system. Problems with it manifest themselves as slow or jerky drum rotation.

- Damaged or deformed bearings. Drum skewing is not a common problem, but a serious one. There are only two things that can cause it. The first is the wear of the oil seals, because of which water can get inside the mechanism, and the parts rust. The second is the long-term use of technology. Due to the fact that the bearing cannot provide the normal movement of the pulley, the belt simply slips along it, which means it is more worn out. This reason can be detected by constant noise, knocking, squeak from the washing machine during operation.

Repair and replacement

If you find that the belt on your washing machine is defective, be sure to check it for damage. If it has holes, scuffs, if it is completely torn, do not try to repair it, but replace it immediately. Do not use a washing machine with a defective part, because during operation it can damage other parts, becoming entangled between moving parts.

Be sure to unplug the system before starting replacement to avoid personal injury.

Remove the rear panel to access the rear of the machine. On some models, this may require removing the top cover.

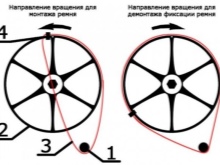

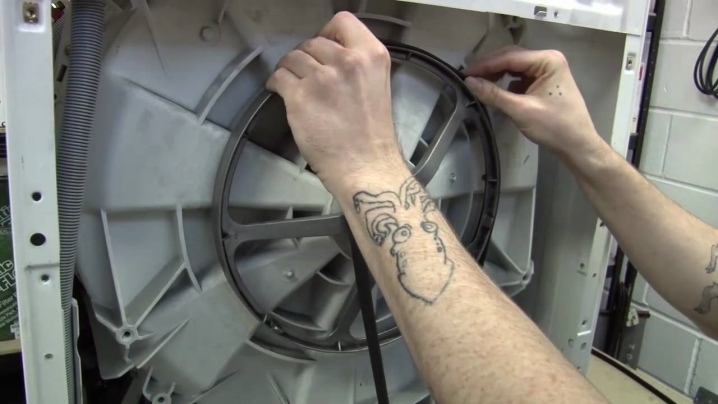

Once you have access, take a look at the strap. It should be tensioned between the motor spindle and the drum pulley. To remove it, pull one of the free edges towards you and turn the drum pulley. The elastic will easily slide off of it.

If you did not find the part in its place, then it could jump off and fall inside the machine. Be sure to remove it before installing a replacement.

Compare the grooves on the new strap and the engine pulley. They must be the same shape. Slide the part onto the engine and begin a revolution around the drum pulley. Rotate it a little while holding the belt to keep it awake. As a result of a complete rotation, the part must completely fall into place. Make sure everything is working correctly by turning the drum a few turns - the elastic should not break off or deform.

Now you can put the back panel back in place, the repair is over.

Changing the drive belt in a Samsung washing machine is easy. By doing it yourself, you will save from 500 to 1000 rubles on the work of the master. And with proper and careful use, this procedure will have to be repeated no earlier than in a few years.

See below for how to replace the strap and shock absorbers on your Samsung washing machine.

The comment was sent successfully.