Why does the washing machine jump and vibrate violently when washing?

Owners of even expensive and most reliable washing machines periodically have to face various problems. Often we are talking about the fact that the device during washing, especially during the spinning process, vibrates strongly, shakes and literally jumps on the floor. In order to quickly and effectively correct the situation, you need to know why such problems arise.

Defining the problem

The washing machine jumps and moves on the floor due to strong vibration. It is she who makes the device make characteristic movements during various wash cycles. It is worth noting that this behavior of the technique is accompanied by a fairly loud noise. As a result, inconveniences are created not only for the owners of the washing machine, but also for their neighbors.

In order to determine as accurately as possible the reasons why the equipment rattles and slips violently during operation, it is necessary to evaluate the sounds emitted. In such cases, the following options are possible.

- If a metallic grinding sound appears during the spinning process, then, most likely, the problem is reduced to failure (wear) of bearings.

- In situations where the machine knocks when washing, we can talk breakage of counterweights, shock absorbers or springs... The sound comes from the drum hitting the body.

- With improper installation, imbalance and improper preparation of equipment for operation, it emits a real roar. It is noteworthy that in such situations, grinding and knocking are usually absent.

To identify the reasons that the SMA "walks" during work, you can try to rock it. If the equipment is installed according to the rules, then it should not move, demonstrating maximum stability. It will also be useful inspection of the rear panel for mechanical damage.

To identify the presence of problems with the shock absorbers, the car will need put it on its side and inspect it. To assess the condition of the counterweights and springs, remove the top and front panels.

It is important to remember that if you have the slightest doubt about your own abilities, it would be most rational to contact the service center and call the master.

Vibration causes

In accordance with the reviews, quite often the owners of machines have to deal with the fact that the equipment vibrates strongly during spinning. This problem is widespread today. Moreover, in such situations, we can talk about a whole list of reasons. These include both minor issues, such as incorrect loading, and serious malfunctions.

Often the reason that the washing machine "jumps" on the floor is foreign objects... During the washing process, small elements are separated from some things (buttons, decorative details, wool balls, bra bones, patches, etc.). All of this can get caught between the drum and the tub, causing vibration.

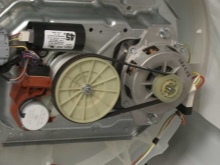

Another common cause of jitters and leaps is loosening of the drive belt. Naturally, we are talking about models equipped with this element. In the process of intensive use of equipment, it can be damaged, fly off the seats and stretch. As a result, the movement becomes uneven, and the whole structure begins to sway.

Bad installation location

In the instructions for each modern SMA, attention is focused on preparing the device for operation. At the same time, one of the key points is the competent choice of a place to install the machine. Mistakes in such situations most often lead to the fact that the technique begins to "dance" in the process of washing and especially spinning. In this case, we are talking about two main points.

- Insufficiently hard and stable floor covering of the room. This can be, in particular, a soft wood floor. In such a situation, the vibration of the machine will inevitably lead to the fact that it will begin to move during operation.

- Uneven coverage. It should be borne in mind that even the presence of facing tiles at the installation site of the equipment is not a guarantee of its stability. It is no secret that, for example, cheap tiles are often not very even. As a result, differences in the level of the floor covering under the legs and wheels of the equipment will only increase the vibrations of the body caused by vibration.

In such situations, the solution to the problem will be as simple as possible. It will be enough to eliminate defects and unevenness of the floor covering in one way or another.

Modern materials, as well as the ability to adjust the position of equipment, will allow you to do this with minimal time costs.

Shipping bolts not removed

The described difficulties have to be faced, including the newly-made owners of automatic machines. Sometimes even a new SMA literally "shakes" during the washing process. If a similar problem appeared when the equipment was first started, then, most likely, when installing it, they forgot to remove the shipping bolts. These fasteners located on the rear panel rigidly fix the drum, preventing mechanical damage during transportation.

After unscrewing these elements, the drum of the machine hangs on the springs. By the way, they are responsible for vibration compensation during washing and spinning. If the bolts are left in place, the rigid drum will inevitably vibrate. As a result, the entire SMA will begin to shake and bounce. In parallel, we can talk about the rapid wear of many components and assemblies..

It is important to remember that the number of transit bolts may vary from model to model. Based on this, it is recommended to carefully study the instructions at the stage of unpacking and installing the equipment. You will need an appropriately sized wrench to remove the fasteners. For example, in situations with Zanussi and Indesit models, this parameter will be 10 mm, and for Bosh, LG and Samsung machines, you will need a 12 mm key.

Breaking

So that the equipment does not "run" on tiles and other flooring, it is necessary to monitor the serviceability of the elements of the vibration damping system. If the equipment is installed correctly, then the reason for its "dancing" will most often be the failure of one or more parts.

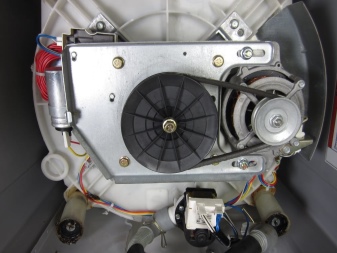

First of all, attention should be paid to assessing the condition of shock absorbers and springs. The main task of these elements is to effectively damp vibrations in the process of unwinding the drum. Over time, and especially when the machine is periodically overloaded, they wear out. Depending on the modification, 2 or 4 shock absorbers can be installed, which are located directly under the drum. You can get to them by turning the device over.

The springs are installed in front of and behind the tank. Problems arise when they are critically worn out, broken, and also in cases where fasteners come off.

As a result of such malfunctions, the tank sags and starts knocking in the process of unwinding against the body.

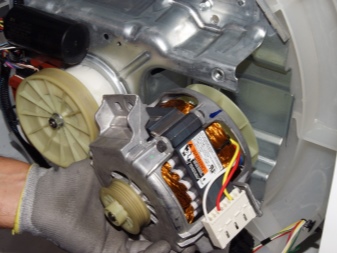

Bearings often fail - plastic or metal elements connecting the drum of the device and the pulley. As a rule, two bearings (external and internal) are installed. In different models, they differ from each other in size, workload, and distance from the drum.

Due to the long-term negative effects of moisture, these elements inevitably oxidize and rust over time. Sometimes wear will lead to bearing destruction. As a result, the drum begins to swing strongly, and its movement becomes uneven. In some areas, it can even wedge up to complete blockage. In such situations, from under the typewriter water flows.

Modern washing machines are equipped with counterweights. We are talking about heavy structures made of plastic or concrete, which are located in front of the drum and behind it. They provide vibration compensation and maximum equipment stability. Counterweights can crumble over time. In addition, the fasteners may loosen.

Another fairly common cause of increased vibration and bouncing of the device is problems with the power unit. It should be noted that most often this is not due to a breakdown of the electric motor, but with the weakening of its fasteners... If there are suspicions of its failure, then it is best to seek professional help.

Incorrect loading of laundry

According to statistics, this is one of the most common reasons for SMA to move across tiles. If the load is incorrect, the laundry will clump together during the wash process. As a result, the weight of wet laundry is unevenly distributed throughout the drum, but concentrated in one place. Because of this, the car begins to swing strongly, taking into account the movement of the resulting coma.

In such a situation, naturally, it will not be about eliminating any problems, but about observing certain rules. You can avoid problems if:

- do not exceed the maximum weight of the loaded laundry, specified in the instructions of each model of the CMA;

- right put things in the drum and do not throw them there in a lump;

- distribute large items evenly, which is washed alone (it is often necessary to periodically interrupt the wash cycle for this).

Most often, problems arise precisely because of overloads.

If the weight of the loaded laundry exceeds the prescribed limits, then it is difficult for the drum to spin up at the required speed. As a result, the entire mass of wet things loads the lower part for a long time. However, a significant underload also adversely affects the operation of the washing machine. In such situations, things are literally thrown around the entire free volume, which in itself causes loosening of the equipment.

How to fix it?

In some cases, you can correct the situation on your own, then you do not have to call the master at home or deliver the AGR to the service center. This refers to the following possible problems and how to fix them.

- If foreign objects get into the drum, remove them. To do this, you need to carefully bend the seal on the front panel, having previously fixed the drum itself. The excess part can be hooked up with a hook or with tweezers and pulled out. If a problem occurs, it may be necessary to partially disassemble the device. In this case, a rational solution would be to contact specialists.

- If the equipment starts jumping due to unevenly distributed laundry, then it is necessary to stop the cycle and drain the water. The laundry must then be removed and re-spread in the drum. When overloading, it is better to remove some of the things.

- To reduce vibrations resulting from improper installation, you should adjust the position of the equipment using a level. To do this, the legs of the machine must be set to the desired height and fixed. The base (if the machine is on a wooden floor) can be leveled using different materials as a backing.

- Any remaining shipping bolts will need to be removed using a wrench or simple pliers. It is important to remember that the number of fasteners will differ from model to model. Some have additional bolts under the top cover.In place of the removed elements, you should install special plastic plugs included in the delivery set. It is recommended to keep the bolts in case of possible transportation of the machine.

- If problems arise with the shock absorbers, then they will need to be dismantled and checked for compression... If they shrink easily, they will need to be replaced. It is important to consider that the shock absorbers must be changed in pairs.

- If you suspect that the counterweights are out of order, it is necessary to remove the machine panel and inspect... If they crumbled, then, if possible, you need to install new ones. However, it is not always possible to find such items on sale. In such situations, you can try to repair damaged counterweights by gluing them or pulling them together with metal plates. If the counterweights are intact, then the reason should be sought in their mountings, as well as in the condition of the springs.

- In situations where the "root of evil" is hidden in the electric motor, it is necessary first of all to try to tighten its mountings. In parallel, it is worth checking the condition and degree of tension of the drive belt.

It is strongly recommended not to carry out other manipulations with the motor, as well as the electronic part (control unit).

It is best to replace worn and damaged bearings in a service center. It should be borne in mind that due to the design features of most models, such a procedure is rather complicated.

Helpful hints

Inexperienced owners of household appliances sometimes do not know what to do if the washing machine begins to "dance" on the floor and how such "dancing" can be prevented. The following guidelines will help you get rid of most potential problems.

- Before using the equipment, you should carefully study the instructions. This document describes not only the rules for using the equipment, but also the main technical characteristics, possible problems and how to solve them.

- Trying to repair new cars yourself is strongly discouraged, as they are under warranty.

- Before taking any steps to reduce vibration and stop SMA jumping, it is necessary to turn it off and completely drain the water from the tank.

- It is best to determine the cause of the device jumping on the floor according to the principle "from simple to complex"... First, make sure that the appliance is installed correctly, as well as check the quality of the flooring and the even distribution of the laundry in the drum. In situations with new CMAs, do not forget about the shipping bolts.

- If you still have to dismantle individual parts, then it is best to mark in any convenient way. You can draw a diagram on paper or photograph each step. This will help, after the end of the work, to correctly install all components and assemblies in place.

- With an insufficient amount of knowledge and skills, all complex it is recommended to entrust manipulations to professionals.

It is important to remember that It is impossible to completely neutralize such a phenomenon as vibration, even in situations with the most expensive modern washing machines. This is due to the peculiarities of the work of this type of household appliances. We are talking, in particular, about the spin mode and rather high speeds.

At the same time, we can distinguish the category of washing machines that vibrate stronger than their counterparts. This refers to narrow models, which have a much smaller footprint. In addition to the reduced stability of such equipment samples, it should be borne in mind that a narrow drum is installed in compact models. In such situations increases the likelihood that the laundry will get into a coma during washing.

Experienced owners and experts advise installing such machines on rubber mats or using foot pads.

Another important point is correct loading of laundry into the drum... As noted above, in the case of knocking things together, an imbalance occurs, leading to increased vibration and displacement of the machine. The amount of laundry should be optimal every time. It is important to remember that both exceeding the norm and underloading negatively affect the work of the SMA (Frequent washing of one item can cause serious damage to the machine). Also, special attention should be paid to distribution of items in the drum before starting the wash cycle.

For even more information on why the washing machine jumps and vibrates strongly when washing, see the next video.

The comment was sent successfully.