Electrolux washing machine error codes: decoding, causes and elimination

Electrolux washing machines are reliable and durable. However, even this technique can break. Let's consider the main types of malfunctions, their causes and remedies.

Malfunctions and their description

Modern models of Electrolux washing machines are equipped with self-diagnosis function. This means that in the event of a malfunction, an error code will appear on the display of the device. The code is an abbreviated indication of the nature of the breakdown, possible causes of its occurrence and options for elimination. The appearance of the code can signal both minor operating errors (for example, a loosely closed hatch door), and serious breakdowns (a burned-out engine).

Let's take a closer look at what error codes are possible when using Electrolux washing machines, and what they mean.

- Error code E10 or E11 (depends on the specific model of the washing machine). Occurs when there is not enough water in the tub for washing. In other words, for a certain period of time, the water level has not reached the specified minimum.

- Error E13. Appears when water leaks into the sump of the machine.

- E20 or E21 code. It occurs in the drain mode, if during the specified time interval (10 minutes) the water has not been drained from the tank.

- Error E23... Malfunction of the drain pump located on the electronic controller triac (control circuit).

- Error E24. Similar to the previous one in place of origin - an electronic controller. However, the failure concerns the deficiency of the drain pump triac control circuit.

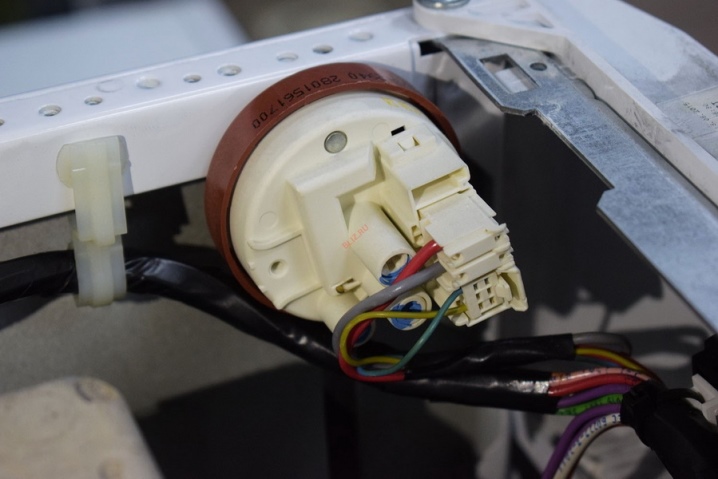

- E31 code... Its appearance on the display indicates a malfunction of the pressure sensor.

- E32 code. There is also a malfunction in the pressure sensor, or rather, in the calibration of this sensor.

- E33 code. It occurs when there is an imbalance in the operation of the water pressure sensors. First of all, the sensors responsible for protecting the heating elements when they are turned on without a set of water.

- Code E34. It occurs when there is a mismatch between the pressure switch and the anti-boil level 2.

- Error E35. Indicates that the water level in the tank is higher than the permissible level. This usually occurs when the overflow level is reached and the overflow level switch is open for more than 15 seconds.

- Error E36. Occurs when the heating element protection sensor is faulty.

- E37 code. Fault signal of the first water level sensor.

- Error E38. It may indicate such a problem as the impossibility of fixing the pressure difference or the blockage of the pressure switch tube.

- Error E39. Overflow level sensor malfunction

- Code E40 or E41. Lights up on the display when the door is not tightly closed. Linen may interfere with closing it. Much less often we are talking about the breakage of the hatch lock and the need to replace it.

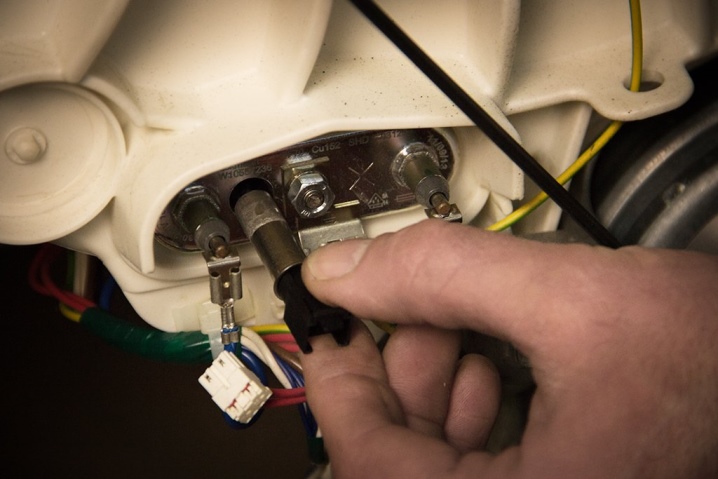

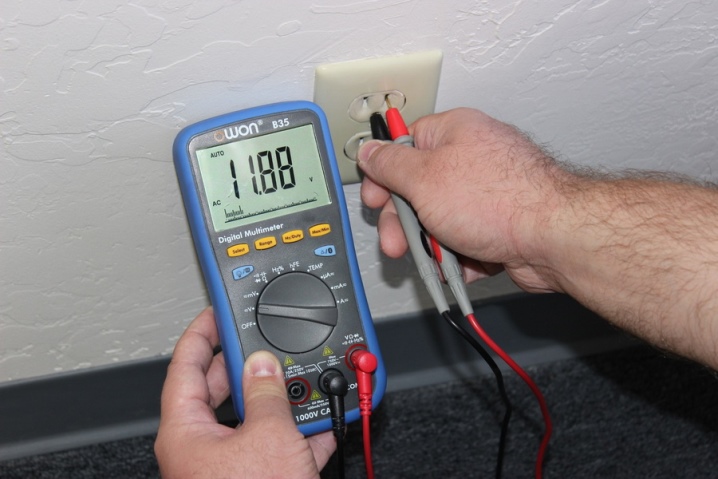

- Error E43. Again associated with a loosely closed hatch door, however, this is a breakdown of the door lock. Its repair is impossible, replacement is required. In addition, this error code can be displayed when the triac breaks down. Its function is to ensure the operation of the hatch lock, the location is a digital board. To understand whether the triac is working properly, it is enough to use a multimeter.

- Error E45. Violation of the circuit, due to which the operation of the triac is carried out. For troubleshooting purposes, first ring each link in this chain.

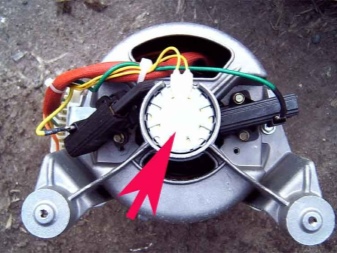

- Code E50. There are many malfunction options hidden under it. This may be a short circuit of the control triac, failure of the tachogenerator and adjacent elements.If these units are in good working order, the reason probably lies in the breakdown of the bearings, the electronic controller, the reverse of the drive motor.

- Code E51. It occurs when the triac of the drive motor breaks down.

- Error E52. The machine issues this code when there is no signal from the tachogenerator located on the drive motor. It also makes sense to check that the counter-regulator coil does not jump out of its cell.

- Code E54. The error appears when one of the starting engine reverse relay is stuck. Usually, this failure is eliminated by replacing the relay with a new one.

- Code E57. The error is associated with exceeding the current 15A. This usually occurs when there are problems with the electrical wiring (its resistance is measured in the first place) or when the engine malfunctions.

- Error E60... An error indicating that the temperature in the cooling radiator has reached 88 C and above. That is, this is an excess of the maximum possible temperature. The machine is "treated" in this case only by replacing the electronic unit.

- E61 code. This error is not displayed in the standard operating mode, but is detected only during a diagnostic run. Indicates insufficient water heating (inappropriate to the selected wash program). Indirectly, the presence of such a malfunction can be suspected by the deteriorated quality of washing.

- Error E62. Occurs when the water heats up too quickly. Typically, this is heating up to 88 C in less than 5 minutes. The error indicates a malfunction of the temperature sensor. If everything is in order with him, the malfunction is caused by a breakdown of the heating elements.

- E66 code. Breakdown of the heating element relay.

- Error E68. Indicates that the current leakage rates are exceeded, which is associated with the need to repair the motor or heating element or replace the control board.

- E70 code. This code indicates a break in the temperature sensor chain.

- E85 code. Damage to the circular pump

- Error E90. Break in communication in the control and indication board. It is necessary to assess the condition of the contact of the connectors - whether they have oxidized.

- Eb0. Lights up on the display when the power supply in the network does not comply with the existing standards. Elimination - the use of voltage stabilizers. Similar to this error eh0. Indicates network overvoltage.

- Error codes ef0, ef2, f20. All these problems are associated with the inability to drain water due to a blockage or malfunction of the hose. Sometimes the hose is simply kinked, which causes the error to be displayed.

Causes

Each of the error codes has a reason (and more often than one) of occurrence. So, error code E11 usually occurs when one of the water inlet valves or its control circuit on the electronic controller breaks down. This is the most common, but not the only reason. Among others - insufficient resistance of the valve winding (the norm is 3.75 Ohm), insufficient water pressure in the water pipes, clogging of the water inlet path.

If there are problems with the drainage of water (error code E21), it is worth checking the serviceability of the drain pump, the permeability of the filters, the pipe and the drain hose. It is the malfunctions and clogging of these elements and units of the machine that most often cause this kind of breakdown. It also makes sense to check the voltage of the drain pump winding (the norm is 170 ohms). Finally, this kind of error can be caused by malfunction of the electronic controller.

Exceeding the drain time can be associated with error EF1, and displaying the code EF2 signals an increase in foaming, the root cause of which is also a blockage in the drain line. In this case, the origins of the problem are sought in the drain hose or sewer, it makes sense to check the filter over the drain pump for clogging.

The reasons for the breakdown of the pressostat are mainly caused by clogging of the tube, malfunctions in the power supply, malfunctions in the program settings. The pressure switch is responsible for the overall performance of the washing machine, otherwise it is called a water sensor and a voltage sensor. That is why the failure of this element leads to the appearance of completely different "symptoms" - premature start of washing, inability to activate the spin function.

Causes of occurrence errors E40-E43 connected with a loosely closed hatch door. It can be trash or foreign objects falling into the lock. That is the search for the cause of the malfunction begins precisely from this zone. If everything is in order with the lock, then the cause of these error codes may be a skewed door. That is, the screws in the bolts loosened, the door "slid", so it is impossible to close it correctly. It is clear that in this case, tighten the bolts tighter with a screwdriver and return the door to the desired position.

Sometimes the reason for a loosely closed door can be hidden in power surges. You can check this in a simple way - disconnect the washing machine from the mains for 10-15 seconds, and then turn it on again. Alternatively, try manually pressing the door to the hatch with your hands and wait for a characteristic click to sound and if the lock icon appears on the display.

Finally, the door may not close properly. wear of machine parts. On average, they are all designed for a 5-year service life. Malfunctions of the electric motor can be detected by the appearance of the error E50 on the display. Moreover, the cause of its occurrence may be a malfunction of the relay, bearings, the absence of a signal from the tachogenerator.

The reasons for this are also different - from a washer that came off the thread to serious malfunctions of the tachogenerator and its natural wear and tear.

One of the weak points of washing machines is the heating element.... One of the common reasons for the failure of a heating element is the formation of scale on its surface. Scale does not allow heat to pass through, that is, the heating element begins to overheat, and the heating of water during washing turns out to be insufficient.

Scale formation is usually associated with high water hardness, the presence of impurities in it, primarily calcium and magnesium salts (which is why deep cleaning filters for water pipes are recommended for use), too aggressive detergents.

Sometimes the heating element, on the contrary, heats the water too quickly and too much. In this case, the "fault" is the temperature sensor, which should be replaced. The relays that control the operation of the heating element may also fail.

Elimination

So, one of the common problems is lack of signals on the display when you turn on the machine to the network. Simply put, she does not react in any way to such actions. First of all, you should check is there electricity in the network - plug other equipment into a power outlet.

You can try to reset the wash program and enter it again.

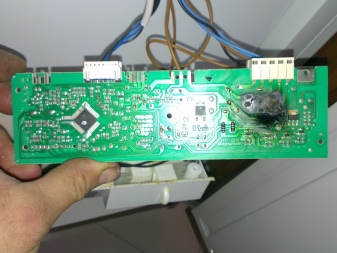

If everything is ok, check the power cord and plug. If damage is found, do not insulate but replace. The reason may be oxidation of the control panel contacts or burnout of the power filter or its elements. Elimination of this type of problem begins with removing the top cover (just unscrew the bolts). You will see the filter at the wall. When it burns out, swelling will be noticeable. In this case the filter must be replaced. To check the keys, you must first remove the tray, after which the buttons will be visible (behind the module).

In the event of oxidation of the contacts, the element is replaced.

In case of problems with the intake and discharge of water, the first thing to do is close the shut-off valve and unscrew the hose from the body... A filter will be found behind it, it is removed and washed under water, the same should be done with the hose. It makes sense to immediately dismantle the back cover and check the inlet valve located behind it with a multimeter (the norm is 2-4 ohms).

If water remains in the tank, the drain should also be cleaned. You can find it behind the door located at the bottom of the machine (on the front side). Opening this door, you will see a filter that needs to be unscrewed. Attention, at this moment water will pour out of the hole, so you should immediately prepare rags and buckets. Having unscrewed the filter, it is washed, as well as the space that it closes.

It is worth wiping the filter dry and screwing it back in.

If the drum begins to spin the laundry poorly, and the machine vibrates strongly, check the tension of the drive belt. To do this, you need to unscrew the back panel of the device. If the belt has fallen off, you will immediately see it, just put it back in place (on the engine pulley). When the belt is worn out, it must be replaced. On machines with a classic motor, it may be necessary to replace the brushes. You need to check their graphite rods (remove from the case by disconnecting the contacts).

If worn by more than half, the brushes must be replaced.

Watch a video on the topic.

The comment was sent successfully.