Do-it-yourself Ardo washing machine repair

Ardo washing machines have been on our market for a long time and are famous for their reliability and long-term trouble-free operation. However, even such famous equipment breaks down. In this article, we will look at how to repair a washing machine from this well-known manufacturer with our own hands and analyze the most common malfunctions.

Design features of Ardo washing machines

Ardo washing machines from an Italian manufacturer Is a moderate combination of price and quality. All units of the described brand have differences in their modern design and a set of necessary functions thought out to the smallest detail. This brand supplies to the market devices with the possibility of frontal or vertical loading of laundry - for example, the Ardo Effective model.

All washing machines for the Russian market have been assembled in Italy since 1997. Models intended for export to Russia are manufactured taking into account the hardness of tap water, and special materials are used to assemble some units.

The key to the durability of these washing machines is their simplicity of design and maintainability of components and assemblies.

High quality washing machines from an Italian manufacturer have the following important components in their design:

- tank - is a special reservoir in which water is accumulated and mixed with used detergents (powder, conditioner);

- drum - movable perforated structural part made of strong metal (located in the tank);

- electric engine - a simple electric motor that rotates the drive mechanism is responsible for the rotation of the drum;

- pump (or drain pump) - electric water pump pumping out water;

- Heating element - an element for heating water in a typewriter;

- electric filling valve - in Ardo machines, this component is fixed at the area of contact between the body and the inlet hose;

- control module - the electronic unit of the unit, where the programmed microcircuit is located;

- control Panel - it can be mechanical or electronic;

- loading door and its blocking device;

- dispenser detergents.

Besides, the design of branded units includes: shock absorbers, rubber bands and filters, sensors, hoses and nozzles.

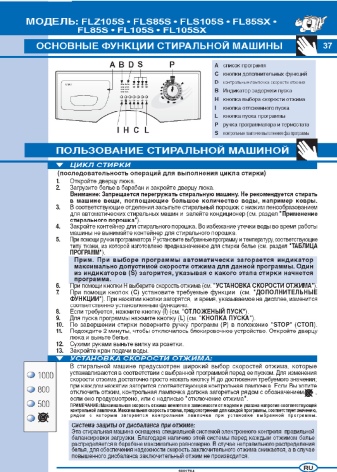

The bulk of modern washing machines of the described brand has the ability to display error codes when a malfunction is detected. Knowing what a specific error code means, you can fix this malfunction at home on your own.

For the convenience of understanding this "language" of your washing machine, there is a special table in the operating manual, which contains the codes of all malfunctions, ways to eliminate them and the reasons for their occurrence.

Causes of breakdowns

There can be many reasons for breakdowns, ranging from carelessness of the owner and ending with wear and tear of mechanisms. Let's consider the most common malfunctions.

- The transit bolts have not been removed. They are necessary for long-term transportation of the machine from the manufacturer's factory to the buyer. Their task is to prevent the tank and shock absorbers from shaking too much on the road, so that the counterweights do not damage the shock absorbers inside the machine itself.After delivery and installation of the machine at a permanent place of work, they must be unscrewed, which the owners often forget to do. Of course, the machine will not work normally with them.

- The car was not leveled. In this case, at high speeds, the machine will shake and make noise. Excessive vibration if not properly seated will negatively affect bearing life. For correct exposure, you can use the building level.

- Poor quality water. Everyone knows the problem of limescale. It forms in kettles, boilers and other heating elements that are in constant contact with tap water. Washing machines are no exception. Their heating elements also suffer from this. After a certain period of time, the water begins to heat up more slowly, and then the heating element will fail altogether.

- Violation of operating rules. Some breakdowns in the operation of washing machines occur due to the negligence of their owners and neglect of the rules for using the devices. Such points include a strong overload of household appliances or the launch of a half-empty drum into operation. It is not advisable to overfill the detergent drawer. Excess wet powder dries up and clogs the feed channel of the mixture, causing the machine to stop working. The required amount of detergent is indicated in the instructions for use.

- Water does not flow after turning on the unit. The water supply hose or the filter at the inlet to the machine may be clogged. In any of these cases, it is necessary to remove the hose and rinse it and the inlet mesh. The second option is a malfunction of the inlet solenoid valve. It does not work due to the failure to receive a signal from the control unit, or the striker has worn out its resource.

- The machine does not turn on after pressing the start button. A disconnected mains lead may be the cause. If the wire is turned on, and work still does not start, then you need to check the technical condition of the plug and socket and, if necessary, redo them. Disassemble and see the connection of contacts. If they are weak or oxidized, they must be cleaned.

Diagnostics

If you decide to repair the washing machine with your own hands, then before that you need to understand exactly what exactly does not work and what you need to pay attention to in the first place. Diagnostics must be performed before replacing a specific part.

In this case, the most visual inspection is a good diagnostic. An obvious problem can be noticed even with a cursory examination.

Burnt contacts, cracks on the case, places of oxidation of contacts - all this suggests that the desired malfunction is located right here.

Modern Ardo machines have self-diagnosis capability... When the automation detects the slightest malfunction in the program, the system displays a code corresponding to this malfunction on the display. If the owner of the machine sees this code in time and knows what it means and how to fix the detected malfunction, then he will be able to avoid serious damage in the future.

Typical malfunctions and how to fix them

Typical breakdowns are such types of malfunctions that are inherent in any washing machine, regardless of the brand or country of manufacture. Often modern household appliances are faced with such a malfunction as:

- water does not drain;

- water does not heat up;

- the door does not open;

- leakage.

The causes of malfunctions that are specific to Ardo brand washing machines are most often as follows.

- Water does not drain. Such a malfunction occurs mainly due to a blockage of the drain channel, which consists of a drain pump and a drain pipe. In rare cases, the problem lies in a pump malfunction.

- The water does not heat up. This can be determined by cold things and stains that have not been washed off. The reason for this breakdown is a malfunction of the heating element or its complete failure.External negative factors (scale and limescale) gradually lead the heating element to an inoperative state, but sometimes the exhausted resource of the part can also lead to this.

- Drum jammed... The electric drive on the Ardo washing machine is belt-driven and works in such a way that if the drive belt comes off the pulley or breaks, the drum stops. Thus, the breakdown can be immediately identified independently. To resume operation, you only need to put on or replace the belt.

- Noise, clicks and extraneous sounds during washing during the rotation of the drum. Most often, such a noise indicates that it is time to immediately replace the bearings on the drum cross. In rare cases, the noise is caused by a foreign object (coin or button) entering the tank. You can change the bearings yourself at home.

- Water flowed... First you need to understand exactly where it flows from and only then draw conclusions. This can be a burst water supply or drain hose, or a burst bearing oil seal.

- Programmer failure... In this case, the machine may not start, stop during operation, or work incorrectly.

- Pouring water into the tank... Such a malfunction may be associated with incorrect operation of the pressure switch or a malfunction in the operation of the electronic unit.

- Washing does not start... The reason for this is often an incompletely closed door lock. To solve this problem, simply open and close the door again.

Let's take a closer look at how to independently cope with some of the most common malfunctions.

The water does not drain from the machine

The first step is to manually drain the existing water from the tank in order to proceed with the repair. For a detailed explanation of how to do this correctly, it is necessary to refer to the instruction manual for the specific model.

After the water drains, you need to open the "dirt filter" hatch and unscrew the filter itself.

After removing all foreign objects from the tray, look at the condition of its seat. There, too, should not be left with unnecessary garbage in the form of coins, buttons and other small elements.

Next, you need to put the filter back in and screw on the lid. An important point is to correctly install the sealing gum. It should lie evenly over the entire plane, and the rib should not protrude beyond the clamping washer. Otherwise, there will be a constant flow of water under an incorrectly installed rubber gasket.

If after cleaning the filter during the next wash, the water does not drain again, then this may indicate more serious problems, such as incorrect operation of the control module or a failed pressure switch.

Noise and iron grinding during operation

This operation of the washing machine may indicate the need to replace the bearings on the drum. This problem can also be identified by wobbling the drum. If it has a backlash relative to the tank, then this indicates a deplorable condition of the bearings and the need to replace them as soon as possible.

After these important parts are completely unusable, their seat will begin to break, and this will lead to the fact that new sets of spare parts will have nowhere to put.

The shaft will begin to cling to the flange and after a while will finally break it. When replacing bearings yourself, you need to carefully dismantle the caliper so as not to damage it.

The door handle is broken

This is a very annoying situation, but you can open the door without calling a professional master. To do this, you will need to remove the top cover. We can now access the inside of the castle. Using a screwdriver or round nose pliers with bent jaws, pry off the metal tongue of the lock and the door will open. The spring and the entire mechanism remain intact, and only the door handle will need to be replaced.

Repair Tips

Before starting repair work, you should familiarize yourself with some useful tips for their successful implementation.

- When choosing new parts for repairing a washing machine, make sure of their quality and compliance with the model of your equipment. Parts of unknown origin may lead to repeated repair.

- Before installing a new part, inspect its seat - it must be free of dirt and lime deposits... If there are any, then they must be removed so that the "fresh" spare part fits as tightly as possible. This will avoid distortions and incorrect work.

- Disassemble the machine carefully, without making any sudden movements.so as not to accidentally damage important parts and connections of the structure.

- The best renovation is the one that didn't exist. In other words, if for some reason you nevertheless partially disassembled the washing machine, then do not be lazy and check all the available parts and elements. So, when you remove the back panel, you will see a belt, a heating element and a motor with all its wiring. Make a visual inspection of all contacts, and if they oxidize, clean them.

- It will not be superfluous to ring the engine and the heating element after removing to clean the contact terminals for excessive resistance or poor contact of the brush. Prevention is the best way to avoid repairs.

The video below tells about possible malfunctions of the Ardo washing machine.

The comment was sent successfully.