Malfunctions of Indesit washing machines

Malfunctions of Indesit washing machines, their cause and diagnosis is a topic of interest to many people who use this technique in their home. The reliability of the products of a popular brand does not raise questions, but with improper operation or wear of parts, failures in work are still inevitable. What to do if there is a constant drainage of water, the machine collects water, but does not wash, is it possible to eliminate these and other breakdowns on your own - all these issues should be considered in more detail.

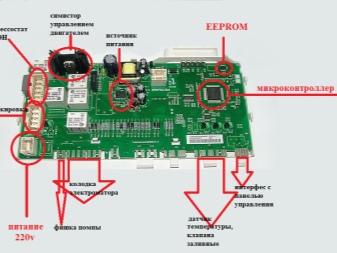

Types of breakdowns in electronics

Modern models of Indesit brand washing machines differ the presence of a rather complex electronic "filling"... A plurality of sensors send signals to a central control unit located in the board. Vibration effects, voltage drops, short circuits in the wiring are just a small part of the reasons why equipment starts to work intermittently. The most common problems deserve special attention.

Engine defective

Among the breakdowns that occur quite often, Indesit washing machines can be distinguished breakage of the motor winding... This mainly applies to older technology series, which uses a belt drive. When the wires in the winding burn out or their integrity is violated for other reasons, the drum stops rotating. At the same time, all other functions of the machine will work in normal mode: indication, drainage and water intake occur without any complaints. Making sure that the burned-out winding is the source of the problem is quite simple. It is necessary to disassemble the car and check the suspicious area with a tester.

If the winding is damaged, no current will flow.

The machine has frozen while rinsing or spinning

When the Indesit washing machine freezes on rinsing, you must first of all pay attention to the fact that at what stage the failure occurs. The frequency of errors is also important. They can appear regularly or periodically, completely disrupt the operation of the equipment, or only suspend it for a short time.

At the beginning of the cycle, equipment hangs are usually associated with with problems in the operation of the water level sensor or filling valve... In this case, the work will be completely stopped. Hanging before spinning indicates an imbalance or excessive load of laundry in the drum... With imbalance protection the technique will stop working.

Also, a similar issue will arise in case of breakage of dampers - shock absorbers to cushion vibration. When the Indesit washing machine freezes, you need to pay attention to whether the technician responds to the commands given by the user using the buttons. In the absence of a reaction, you need diagnose the electronic unit.

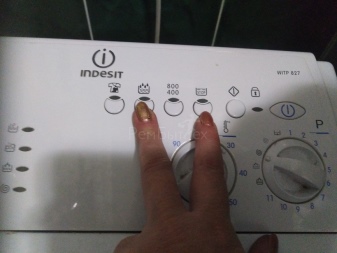

The indication on the button disappeared

The indicator lights on analogue controlled Indesit washing machines are quite important. With their help, the technique signals about breakdowns, informs about the transition to a specific stage of its work... When the equipment is subjected to vibration during operation or condensation forms inside the case, the terminals responsible for connecting the buttons to the control unit oxidize or may come off. The contact will be lost; pressing the key will not work. The way to fix the problem will be quite standard: finding a place where there is no connection, it is restored by soldering.

Breakdown of the pressure switch

When no water flows into the tub even after setting the desired wash program, rinsing and spinning will stop activating, the water level sensor is likely the source of the problem. This part of the product is called the pressure switch and located at the bottom of the tank. When the water level sensor is defective, the electronic display may show error code F04 or F10. At the same time, the Indesit washing machine will not be able to determine both the correct level and the presence of liquid in the tank.

Only a complete replacement will help to eliminate the problem of an inoperative pressure switch.

Heating element does not heat

The water in the washing machine is heated with a heating element - a part that resembles a large boiler. Despite its impressive status, Indesit sometimes uses not the best quality components in its equipment. A steel heating element without an additional anti-corrosion coating quickly fails when in contact with hard water. The formation of a calcified deposit on the surface of the heater impairs its thermal conductivity, leading to the fact that the part burns out.

Signs that the heating element does not fulfill its tasks include keeping the door glass cold during washing, poor washing out of powder from the dispenser container. Dismantling a part of the case and ringing the part with a tester will help to accurately establish the cause of the malfunction. You need to check the right and left terminals, the middle one is needed for grounding. If the heater is out of order, it can only be replaced with a new, similar part.

Broken control unit

Indesit washing machines equipped with mechanical programmers were practically invulnerable to all kinds of breakdowns. The standard service life of the control module in them reached 10 years. In models with an electronic display and buttons for switching modes, this part is much more vulnerable. Failure of the program is a fairly common breakdown, in addition, when the control unit fails, the following symptoms may be observed:

- the spin mode does not turn on;

- light indicators on the case blink chaotically;

- the display lights up codes F18, F09;

- the machine does not turn off on time, washing takes longer than usual;

- constant drainage of water.

As a rule, replacement of a part is not necessary. When the unit immediately drains and collects water again, shows other signs of failure, you should call a service technician. He will carry out a flashing and restore the operation of the electronic unit. After installing the correct software, the technician will fully restore its performance.

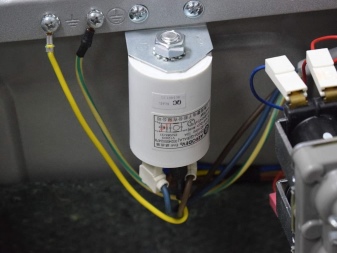

Defective mains filter

If the automatic machine refuses to work, the washing program does not start, there is no water in the tank, it is worth checking just one, but very important detail from the very beginning. The surge protector looks like a compact unit equipped with a wire spool. It is quite easy to find it inside the case: the part is located immediately behind the wall of the case, after the wires enter it. The purpose of the mains filter is to protect equipment from voltage surges, short circuits.

In the Indesit washing machine, the surge protector is one of the parts that often fail. The cause of the problems is in the condensate settling on its surface. The only way to eliminate the breakage is complete replacement of the part.

You will have to remove the housing cover, unsolder it and fix the new surge protector in the place intended for it.

Mechanical faults

Sometimes problems in the operation of Indesit washing machines are not related to electrical and electronic components at all. Mechanical structural elements available in this technique, no less often create difficulties in its operation. Eliminating the breakdown in this case can take much less time, because in most cases it will be enough to simply remove the blockage that has arisen.When the drum does not rotate, the machine does not wash, and the electronics are in good order, you should pay attention for possible clogging of the inside of the case. Debris inside can jam rotating parts.

Drain filter clogged

This malfunction occurs most often and is common not only among Indesit washing machines. The filter, installed in front of the drain hole of the washing machine, serves to trap dirt from the drum. Its cleaning is often not given due attention, while the part is clogged with hair, threads, animal hair, and other small particles of washed off dirt. If there are too many accumulated particles, the equipment will not be able to drain the water, a blockage will form in the water path. Troubleshooting in the case of a clogged drain filter takes a minimum of time and is as follows.

- Stopping a wash program... You cannot continue the process until the blockage is removed.

- Disconnecting the mains supply of equipment... A de-energized washing machine is a source of increased electrical hazard. Do not carry out any repair or maintenance work while the appliance is plugged in.

- Unscrewing the drain plug from the hole. It is dismantled by substituting a cuvette or other container for draining water under the hole.

- Garbage removal... Cleaning is done by hand first, then the part will need to be rinsed to remove other contaminants.

- Checking the filter compartment... It is likely that some of the contamination is also in it.

- Replacing the filter... Then you can connect the equipment to the network, start the rinsing program.

Despite the step-by-step execution of the procedure, cleaning takes very little time. You don't have to interrupt the wash for a long time.

The car makes noise and vibrates

A situation in which the Indesit washing machine makes a lot of noise during spinning, occurs when:

- the laundry is poorly distributed in the drum;

- a solid foreign object has got inside;

- the pump is clogged, the water cannot be drained.

As a rule, to eliminate such a problem, nyou have to stop the machine, redistribute crumpled laundry or remove the source of noise... Everything happens after the water is drained through the filter, if the equipment itself cannot reset it.

Leakage underneath the door

When water flows strongly from under the door while the washing machine is running, you need to pay attention to the condition of the cuff framing the hole. It is responsible for sealing the hatch, is made of elastic rubber and can be easily damaged by contact with hard sharp objects. In addition, over time, the cuff shrinks, dries out and no longer adheres to the fabric enough. Helps to solve the problem replacing this element or gluing a small damage with a special compound and a rubber patch.

The hatch is not blocked

Indesit electronic display washing machines report that the door has ceased to be fixed. On fire Door signal will tell you that there was a breakdown. When the door of the unit does not close, this may be due to the failure of the lock, cuff or linen hitting the target. In this case, the mechanical obstruction can be easily removed. If rubber seal damaged, it is better to replace it. Breakage of the castle the blocker or the sensor responsible for it requires contacting the service center.

The machine does not draw up water

Indesit equipment is equipped with a rather sophisticated filtration system. When the equipment does not collect water, the reason most often becomes a blockage in the feed filter. It is mounted at the water inlet to the body, is in the discharge line in front of the tap and serves to retain small debris, rust, and other contaminants. If the plumbing system is not too new, the filter clogs up faster and the flow rate decreases. Virtually no liquid seeps through the filter and into the drum.

It is possible to diagnose a breakdown not only by problems with the water supply. A start delay, not accompanied by interruptions in the indicator signals, indicates that the pressure is clearly insufficient. To fix the problem, it will be enough simply unscrew all places where filters are installed and clean them from debris.

You can do this yourself.

Broken bearing or axle sleeve

A crack or creak, a rattle heard when the drum rotates, will report a breakdown. Usually, the problem arises after 6-8 years of using technology... Due to the drying out of the lubricant, friction between the parts increases. The bearing simply crumbles and requires replacement. If the bushing breaks down, then replacing it will require dismantling the entire drum. Elimination of this problem requires sufficient experience. It is better to entrust the replacement of parts to a specialist. Sometimes the drum wall needs to be sawed to remove the bearing. This is done at the seam, from the outside.

How is it diagnosed?

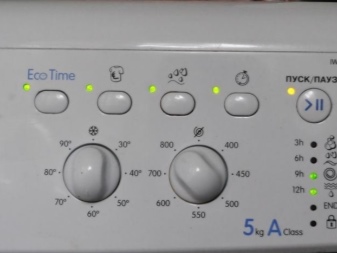

Diagnosing faults in a washing machine always begins with studying the instructions for it. There are a number of breakdowns that you can identify and fix yourself. Almost all modern Indesit washing machines have an electronic scoreboard or display on which error codes appear that determine what kind of failure has occurred in the system. In older models, a different approach is taken: signals are generated using light indicators located on the front panel and in normal times serving to indicate various modes and functions. Not all users are ready to recognize such signals on their own. Here you can focus on simple visual observations:

- availability of power supply from the network;

- the appearance of the reaction of indicators when turning on, trying to start;

- the sound of the engine;

- drum rotation;

- extraneous sounds during work (squeak, creak, rattle);

- the presence of leaks;

- water supply to the tank;

- discharge of liquid into the sewer.

If the Indesit washing machine is clearly abnormal, you need to try to determine their localization and conduct a more accurate diagnosis by visual inspection or manually. Models with electronic display will display error codes. Some of them are characteristic only for certain types of equipment. For example, top-loading washing machines may have code F16, indicating problems with unlocking the drum. Front-loading vehicles do not have it.

F14 is a code that is relevant only for washer-dryers, it allows you to diagnose the failure of the drying function.

There are breakdowns that cannot be eliminated without contacting a service center. It is obligatory to call the wizard for an error with code F18 - this means that the electronic unit is out of order. A wire break or short circuit in the motor will be reported by a signal F1, F06 indicates the absence of contacts in the loops, F09 - a sign of a software error, sometimes it is enough to restart the unit to solve the problem.

When the display shows DOOR or F17, you need to check the correct closing of the hatch. It may not block due to an obstacle caught in the target - a rubber sealing cuff, incorrectly placed laundry. All possible errors with codes are indicated in the operating instructions for the equipment, in many cases it is possible to cope with the problem without contacting the service center.

Prophylaxis

There are certain preventive measures to help prevent possible breakdown of your Indesit washing machine. Observing simple safety measures, you can significantly extend the service life of the equipment, ensure its long-term trouble-free operation. Among the useful recommendations for owners of equipment of this brand, one can single out the following.

- Routine prophylaxis after each wash. It consists of wiping the door cuff, cleaning the filter, cleaning the powder tray.It is also recommended to regularly clean the body of the washing machine from powder, fingerprints, grease and other contaminants.

- Ventilation through the hatch... A simple but effective rule - at the end of the wash cycle, the door of the washing machine is always left open. This will allow the moisture remaining inside to evaporate, prevent the appearance of fungus and mold, bacterial plaque inside the equipment case.

- Cleaning the drain filter... It is located on the front or back of the washing machine, closed with a special shield or door, depending on the model. It is the regular cleaning of the drain filter that guarantees that a specific unpleasant odor does not appear inside the equipment. To perform work, this part is unscrewed, accumulated debris is manually removed, the plastic base is washed under running water. After complete cleaning, the part can be reinstalled.

- Regular cleaning of the system. In modern models of washing machines for this there is a "Self-cleaning" mode, similar to that used when starting the equipment. The machine starts up without laundry, the cleaning agent is put in the powder compartment. The duration of this wash is 45 to 70 minutes. It is recommended to carry out a preventive launch at intervals of 1 time in 6 months or after 40-50 times of using the equipment in normal mode.

- Water softening. For this, a special filter is used, installed in the pipeline between the inlet hose of the machine and the water supply system. When passing through the components placed in the flask, the water becomes less hard, with systematic use, this allows you to avoid damage to the internal parts of the equipment due to calcified deposits.

- Once every 3 years, it is recommended to carry out full preventive maintenance of the washing machine with complete dismantling and checking the degree of wear of the parts. As part of the service, in this case, an inspection of the pipes, engine, pump, and other mechanical parts is carried out. This approach allows you to timely identify the wear of parts, replace them without waiting for emergencies.

By observing these recommendations, each owner of the Indesit washing machine can provide it with a long and comfortable operation without failures, errors and breakdowns.

For information on how to determine the error code in Indesit washing machines, see the following video.

The comment was sent successfully.