How are top-loading washing machines repaired?

The improvement of living quarters and the creation of comfortable living conditions is a complex technical and design process that requires not only theoretical, but also practical knowledge, especially for apartments with a small area. In these living quarters, it is very difficult to place classic washing machines, which require a large amount of space.

Given this problem, manufacturers have developed vertical household appliances for washing, which can organically fit into even the smallest room. Despite its practicality, vertical washing machines are prone to frequent breakdowns, which must be promptly eliminated and prevented from time to time.

Design features

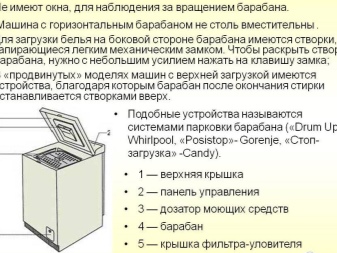

The top-loading washing machine is a compact household appliance that, despite its small size, is less popular than classic models.

Before purchasing this device, experts recommend that you carefully study all its technical characteristics and design features.

The main disadvantages of a top loading washing machine:

- the complexity of disassembly and tightness of the nodes;

- high vibration intensity during spinning;

- inability to adjust the height of the rear legs;

- the formation of rust on the top cover;

- frequent imbalance;

- spontaneous opening of the device doors.

Despite the presence of negative factors, this household appliance has a number of advantages:

- compact size;

- narrow and deep shape;

- ease of use and convenient linen insertion;

- the presence of a program stop function and an additional load of linen;

- safe location of the control panel.

Despite the non-standard appearance, the top-loading washing machine comes standard with:

- pressure switch;

- water intake valve;

- metal drum;

- tank;

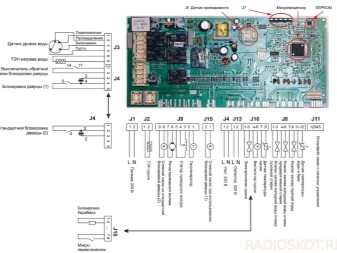

- automatic control board;

- electrical module;

- Exhaust valve;

- drain pump;

- Heating element;

- belt;

- Electrical engine.

The main features are the fixation of the drum axis on two bearings and the position of the drum with the flaps up.

Typical malfunctions

Among the huge number of malfunctions of vertical washing machines experts recommend paying attention to the following problems and methods of detecting a malfunction:

- drain filter leak - checking the tightness of the filter installation and the absence of deformed areas on the seal;

- deformation of the rubber seal on the upper door - removing the control panel and checking the rubber for rust and rupture points (the first sign is the appearance of water under household appliances);

- poor connection of the water pipe at the filler valve - the presence of traces of moisture on the element, as well as places of damage;

- damage to the drain and drain hose - mechanical inspection of parts after the appearance of a leak;

- deformation of the tank walls - removing the top panel and carrying out a visual inspection of the device for the presence of faulty areas;

- wear of the drum bearing oil seals - carrying out regular inspection of devices.

A difficult and dangerous breakdown is the spontaneous opening of the door of the washing machine during its operation. This malfunction seems insignificant only at first glance, however, experts recommend paying special attention to it. Open doors will surely provoke a breakdown of the heating element, as well as cause the drum to block and break.

Due to the fact that all of the above elements are expensive parts, their replacement or repair will require significant material costs.

Also often occurs a problem with the top cover, the surface of which can become rusty from frequent contact with water. This is due to the design features of the top-loading machine. Often housewives are faced with the fact that the drum is spinning tightly, the drum clicks or is stuck, the laundry does not turn over, the disc is broken or unscrewed, and the top hatch is blocked. These problems can be solved both independently, having experience in repairing household appliances, and with the help of special service centers.

How to disassemble?

Repairing the washing machine and carrying out preventive measures requires mandatory disassembly of the device. In order to remove the panels and dismantle the assemblies, it is necessary to perform a number of the following measures:

- releasing the control panel with a screwdriver from the side;

- displacement of the panel by sliding it towards you;

- tilting the device at a slight angle to disconnect the wires from the board connectors;

- dismantling the panel.

To disconnect the electrical control module, it is necessary to disconnect the remaining wires and unscrew all fixing screws. Dismantling the water inlet valve must be carried out by disconnecting the rubber hoses from the clamp. To dismantle the side panels, unscrew the fixing screws and, using a minimum amount of force, slide the panel down. After removing the side elements, it is necessary to start removing the top panel by unscrewing the special screws.

To remove the ram, it is enough to dismantle only the right panel. If the disassembly is carried out independently at home, then experts recommend that you take pictures of all stages of work, which will greatly simplify the process of assembling the device later. In the process of work, it is imperative to rely on the special diagrams of the device and the manufacturer's recommendations.

How is the repair carried out?

Repair of a top-loading washing machine must be carried out in the same way as the established norms and rules for the repair of this household appliance. Leaks in the rubber tube can be eliminated by removing it and sealing with special silicone. After the measures taken, the part must be installed in its original place. To prevent water from flowing through the rubber cuff, tighten the clamp regularly.

This procedure can be carried out using conventional pliers.

It is possible to remove the leakage at the junction of the drain pipe with the filling valve using the following measures:

- dismantling of equipment and fasteners;

- lubrication of all elements with special silicone;

- installation of processed elements in their original place;

- carrying out tightening the clamp.

Particular attention must be paid to bearing replacement. This procedure consists of the following steps:

- disconnecting all wires;

- dismantling the linings that are on the sides of the drum;

- initial dismantling of a part without a pulley;

- retrieving the second element;

- installation of new oil seals and bearings;

- thorough cleaning and lubrication of all joints.

If there are corrosive deposits on the surface of the cover, it must be completely replaced. In this case, repair is impossible in all cases. In the event of a breakdown of the heating element, it is necessary to perform a number of the following measures:

- dismantling the back or side panel;

- disconnection of the grounding and power terminals from the heating element;

- dismantling the fixing bolt, which is located in the center between the contacts;

- the most careful removal of the broken element;

- installing a new heating device and simultaneously fixing it with bolts;

- connecting the power and ground terminals;

- installation of all dismantled elements.

If a problem occurs in the operation of the control unit, then before taking the device to a specialized workshop, you must independently inspect all terminals, contacts and wires for contamination.

If this measure is ineffective experts recommend a complete replacement of the unit.

A top-loading washing machine is a modern type of household appliance that is designed for apartments with a small area... Despite the design features of the device and the presence of a number of shortcomings, experts advise not to abandon the purchase of the device, but to carefully study its features and follow the operating instructions exactly. To extend the life of the washing machine, experts recommend not to ignore even minimal breakdowns that can provoke serious problems.

See below for how to replace the drum supports.

The comment was sent successfully.