Shock absorbers in a washing machine: characteristics, replacement and repair

Shock absorbers in the washing machine play an important role, on which the performance of the unit depends. Each user should know how to identify the malfunction of this part, repair it or replace it if necessary.

Device and principle of operation

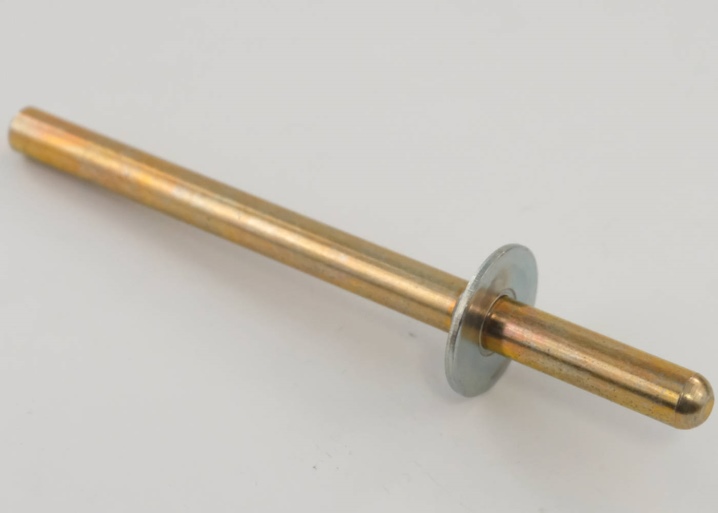

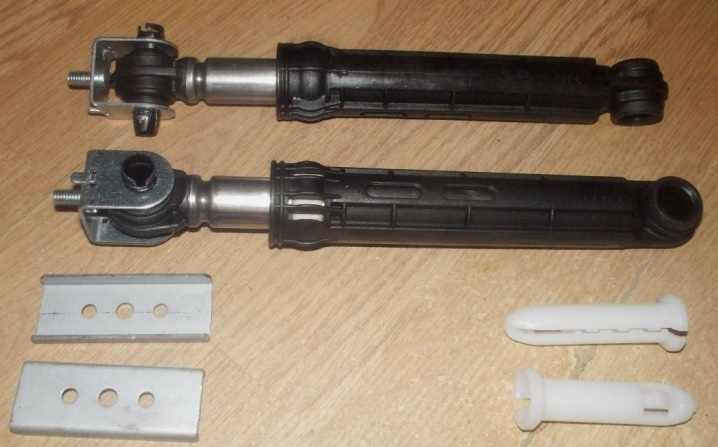

Shock absorber in the washing machine - this is an important detail, without which no device can function normally. This element is a small body part, inside which there is a piston with a return spring, a gasket, a rod and fixing bushings.

There are vertical shock absorbers, as well as variations that are located at a slight angle.

There are also parts that are fixed to both the body and the drum, as well as components with a standard mount only to the body of the washing machine.

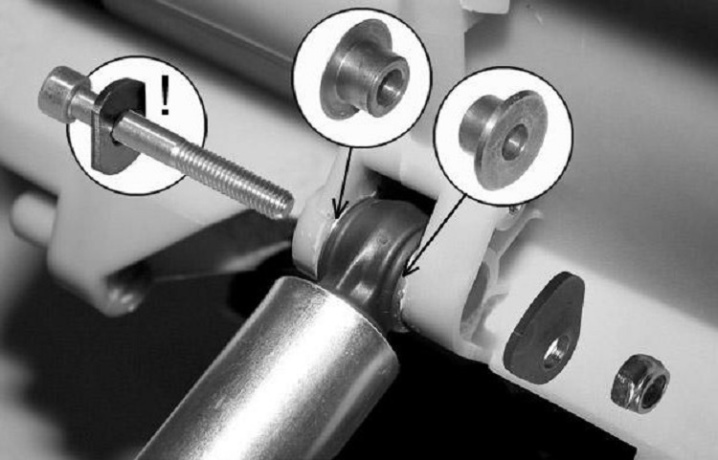

Bushings equipped with latches or bolts are used as retainers. With their help, you can provide high-quality fixation of the shock absorber in the lower body of the unit, as well as on the side surface. In the role of fasteners, return springs are used, which are considered a key component in depreciation.

Shock absorbers are not universal parts, therefore, their appearance may differ depending on the model of the device for which they were made. Each variety is aimed at working with a certain mass of things that are loaded into the drum. It should be noted that the shock absorber is able to absorb vibration of 40-180 N in home devices, and for professional units this figure is much higher.

Shock absorbers differ in their size, the diameter of the holes for installation.

Appointment

Depreciation is a French word that means "damping". From this it becomes clear that shock absorbers are aimed at damping vibration flows that occur during washing or spinning. It is due to such a detail that the movable part of the drum is located in the body of the machine, on springs.

The vocation of the shock absorber is aimed at absorbing shocks and shocks that come from the side of the washing machine tank. This detail is especially important when the drum rotation speed is 800-1000 rpm.

The damping is carried out due to the reciprocating movement of the piston present in the cylinder.

Reverse actions are carried out by means of a return spring. When the rod starts to move in the cylinder, friction occurs. It also normalizes vibrational flows.

What is the difference between shock absorbers and dampers?

The difference between a damper and a shock absorber is that the first component in the structure does not have a return spring. They are located separately and the tank is hung on them.

Both parts (both the damper and the shock absorber) are located at the bottom of the unit and there are two components in the device.

Another difference between the damper and the shock absorber is that the degree of damping of tank vibrations in the first component is much higher. Since the return spring is located separately, in the event of breakage or stretching, you can easily replace the part. But the shock absorber requires disassembly.

Symptoms and causes of malfunction

In addition to the natural reasons for which the performance of the shock absorber is disrupted, which is affected by loads from the drum, high humidity, temperature drops, there are other options for malfunctions.

- The presence of a factory defect. You can often encounter a situation when poor quality gaskets were present in the configuration. Inadequate quality of parts leads to the fact that after using the washing machine, the shock absorber begins to fail quickly.

- Illiterate balancing of the washing machine when using... If the unit is installed incorrectly, there will be an uneven distribution of the load between the shock absorbers, which will lead to rapid wear.

- If you constantly overload the tank of the machine, You may also encounter a situation where the shock absorbers do not work.

- If the machine is running at high speed and there is a power outage. Abrupt braking of a loaded drum can lead to the fact that the springs are damaged.

You can check the condition of the shock absorbers using the following steps.

- First of all you need dismantle the top cover washing machine. To do this, simply unscrew the fastening bolts.

- Then follows push the top of the drum so that it lowered by 5-7 cm. After that, it is abruptly released.

- You can determine the state of the shock absorbers by observing: if the drum goes up and stops, then the part is in good condition. If the tank is swinging from side to side, repair work will be required.

Do not neglect the repair of the shock absorber, as a component in a faulty condition will affect the performance of the machine.

Diagnostics may be required in the following cases.

- During washing and spinning, extraneous sounds are heard: creaking and knocking.

- The drum turns with effort. With this "symptom", it may be necessary to lubricate the shock absorber.

How to remove?

To replace the shock absorber, you need to get to it first. Depending on the brand of the washing machine the part can be located from different sides... Some units have a comfortable location, due to which it is only necessary to dismantle the rear cover, while others require more steps to remove the front housing cover.

Replacing the shock absorber, which is located behind the front cover, is as follows.

- Should dismantle the upper case cover. To do this, simply unscrew the screws and slide the cover back.

- Then remove powder receptacle together with the bottom panel.

- Now you can start to dismantle the top panel. It folds up so that the wires are not damaged.

- The clamp is unclenched, the cuff is removed. The last part should be filled into the tank.

- The fastening bolts are unscrewed, which belong to the front of the unit.

- Then follows remove wiresthat reach for the lock of the hatch. You can also completely unscrew the lock.

- Now you can dismantle the front part. Shock absorbers are located below the tank.

- The next step is unscrewing the bolt, with the help of which the parts are screwed to the body part. On some models, it is enough to remove the latch.

- The shock absorber is detached from the drum... At this stage, you only need to remove the faulty component, repair or replace it.

- No matter what condition the second shock absorber is in, both components always change.

Not every model of washing machine allows you to dismantle the shock absorber without removing the drum. If we are talking about Samsung or Hansa equipment, the procedure will not work without removing the tank. This is due to the fact that the shock absorber cannot be detached from the tank.

How to repair?

In most cases, shock absorber repairs will be required due to the following types of breakdowns.

- Abrasion of the liner or gasket. It is not always possible to restore a broken part; in some cases, it will need to be replaced.

- Mechanical deformation, formed due to illiterate transportation of the device, factory defect.

- Worn shock absorber mounting bolts. In this case, the part flies from its place of fixation and begins to dangle.

Experts recommend in the presence of any damper damper do not use the washing machine until they are restored.

To fix the shock absorber with your own hands, you will need diagnose the cause of the malfunction. To do this, you need to open access to the shock absorber according to the instructions described in the previous paragraph. Then you need to determine the state of the part by compressing it: if the component compresses and expands with ease, then it needs to be replaced.

A shock absorber that is compressed with force is considered functional.

For repair, you will need to pull out the shock absorber insert. If the stem moves easily without an insert, this indicates that the gasket needs to be replaced. To do this, you need to take a belt with a thickness of 3 mm. A piece is cut from it, the diameter of which is identical to the device. The cut piece is placed in place of the gasket and lubricated to improve friction. The procedure is recommended to be carried out before the stem is mounted. After that, you can put the stem back in place.

If the part contains changes of a mechanical nature, caused by defects or wear, the best option is to replace the component. You should remember the brand of your shock absorber and find the same in the store.

Buying a shock absorber at random is unacceptable because not every model can fit a particular washing machine. Experts recommend taking an old part with you to the store in order to ensure that the right component is selected.

How and with what to lubricate?

First of all, you should decide what kind of lubricant is suitable for the job. Professional craftsmen do not advise using different types of lubricant, but using one.

When choosing, remember the characteristics of a suitable lubricant:

- moisture resistance;

- high viscosity;

- resistance to high temperatures (immune to 100 degrees Celsius);

- neutrality.

It is necessary to lubricate the shock absorber before installing the stem. A safe bet is to use a simple lubricating oil.

Recommendations

To extend the life of the shock absorber and prevent damage to it, you should use some recommendations from experts.

- Care must be taken to ensure that the installation of the washing machine is correct. Installation must be carried out on a level, horizontal surface that is sufficiently rigid.

- Do not overload the tank. Each machine has its own load limit, which must be observed in order for the shock absorbers to work for a long time.

- It is necessary to exclude the ingress of foreign objects into the drum.

- During the operation of the washing machine, you need to monitor the sounds that come from the unit. If extraneous sounds are observed, equipment diagnostics will be required.

How to replace shock absorbers in a Bosch washing machine, see below.

The comment was sent successfully.