Washing machine pump: device, location and repair

Each washing machine is equipped with two pumps: inlet, which takes water from the water supply, and drain, which discharges waste water into the sewer after washing. The functions of the pump are taken over by the drain pump, which also has the ability to work in the opposite direction.

Appointment

The automatic washing machine (CMA) is equipped with a pump that performs two functions:

- pumping water into the washing machine tank before starting the washing drum and when switching to rinsing freshly washed laundry;

- rapid removal of waste water at the end of the main washing process and during spinning after rinsing.

The main parts of the pump - impeller with electric motor and volute-shaped channel. The pump is equipped with a drain hose at the outlet, and there is also a branch pipe for pouring fresh running water from the water supply line.

The pump device is quite simple, but a mistake in its operation will lead to a stop of the automatic washing machine.

Types and their structure

The pumps operating in the SMA are divided into two types, each of which has its own filter and its own "snail" structure.

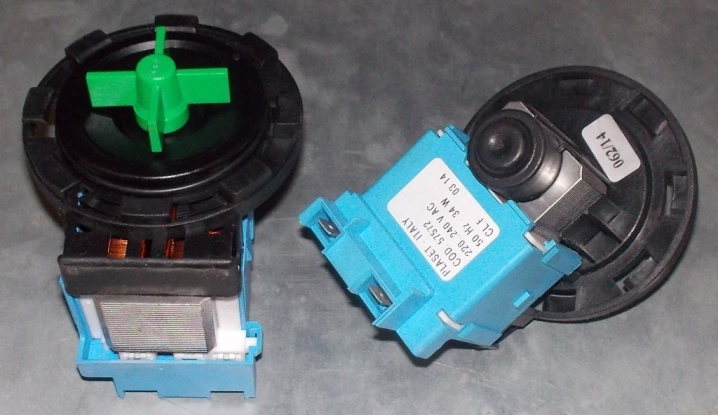

Draining

The drain pump is an attribute of washing machines of the lower and middle price ranges. They are equipped with a conventional pump that drains waste water from the car into the sewer. Most likely, it will not be possible to repair such a pump - the damaged pump is completely replaced with a new one. The power consumption of a conventional pump does not exceed 40 watts. Fastening to the cochlear channel - by screws or by means of latches. The contacts of the electric motor are located separately or together. The disadvantage of a simple pump is the frequent clogging of the filter, due to which the drain is not completely drained, the waste water stagnates inside the channel and a corresponding smell appears from the drain pump. A simple pump requires regular monitoring of the filter condition.

The operation of a simple CMA pump is not that difficult. The fact is that the pump rotor is a permanent cylindrical magnet located in a plastic case. At the start of the drainage system, the rotor itself starts up first, followed by the impeller, which is located on the shaft at an angle of 180 degrees. The impeller should not deviate significantly from its anchored position - such a small stroke allows the motor to start without much effort at high speeds, since the water also resists the propeller itself. The magnetic core has two coils connected at the ends. In other words, a simple pump drive is a small asynchronous motor that contains a rotor and stator. The stator contains a magnetic stationary part of the rotator with windings, and the rotor contains a magnetic core.

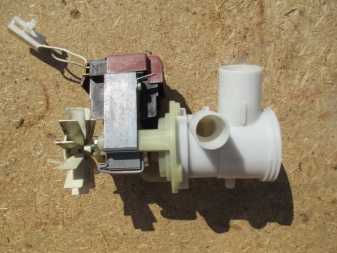

Circulating

A circular (booster) pump can be used in conjunction with a simple (drainage) pump. Such a system for pumping and pumping fluid is used in the middle and upper price ranges. Advantages - water supply directly to the drum, the possibility of circulation (this allows you to reduce water consumption for washing clothes). The principle of operation of a circular pump - water is passed only in one direction along a closed path.

So, Samsung uses a seal in a circular system - it does not allow water to go outside the circuit. The bearings remain dry.This mechanism has a shaft on the rotor that passes through a sealing sleeve that works with a spring-loaded compression ring. To lubricate such a mechanism, a special thickened composition is used that penetrates into all rubbing places.

Thanks to him, the mechanism does not experience "lubricant hunger" and works reliably for a number of years, showing excellent performance.

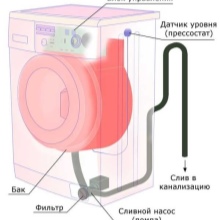

Where is?

The pump can be located on three sides.

- In the lower part - a widely used design. To get to the pump, you need to open the bottom of the MCA. The car is piled on one side and the bottom wall of the hull is removed.

- In the back. The SMA is moved away from the wall. The rear wall is removed, held by bolts. There is no need to turn the car. The task of replacing and repairing a pump becomes much easier. The pump is located at the bottom.

- Under the front panel... To dismantle it, it is often necessary to remove the rear wall, where additional bolts are located to give access to the front latches.

According to the structural diagram, the pump is never placed on top - such a connection would additionally load the drain pump. The water would not only have to be pushed out into the horizontal drain, but at first it would also have to be lifted up, to a height of almost a meter.

This will either require high power costs, or prematurely disable the drain pump.

Causes of malfunctions

In general, according to statistics, pumps and pumps are designed for an 11-year service life - if the owners of a single MCA before washing the laundry recheck their pockets and take out all that is unnecessary... In this case, the clothes are turned inside out so that buttons, plaques and locks do not damage the drum, do not fall off and do not clog the pump.

Along with unnecessary items and loose accessories, the pump is dangerous due to dirt and scale... Before washing, say, jeans, which on the highway were sprayed with mud from puddles by a KamAZ with a 20-ton truck, having rushed past you, the pants should be dried and cleaned, and the dirty scab should be shaken off them. Sand, often contained in mud, settles in the pump and clogs the filter, and if it is still possible to squeeze it out of the filter membrane with a powerful pressure, it will clog the drain hose and settle in the general sewage system. The impeller and the "snail" suffer from the build-up of clay - the pumping of waste water noticeably worsens, and the load on the pump motor gradually increases.

The mechanics are also impermanent, therefore, even if the user of the CMA did not violate the rules, observed all the restrictions that make the operation of the unit safe and fast, then sooner or later the motor will wear out, the pressure impeller will crack. Even the use of a stainless steel impeller and bearings will not save the owner of the washing machine from pump breakdown due to wear and tear from many years of MTBF.

Be that as it may, the worn out pump must be replaced.

Malfunction symptoms

If the pump runs continuously for a long time:

- water continues to flow due to the failure of the filler valve, and the machine constantly pumps out excess water in order to prevent the drum from overfilling;

- the drain is poorly pumped (filter clogged);

- the electronic control from the ECU of the washing machine has failed.

From long, continuous operation, the pump gets very hot. It turns off due to overheating - the heat sensor will work. If this did not happen, it hummed, which means that some of the components, for example, the impeller or bearings, have worn out, or one of the windings has shorted out. The option is possible when it pops, buzzes or makes noise:

- the water being poured has a poor pressure, and he collects it, spending additional efforts, noise is observed if the water was recently turned off, a lot of air got into the water supply system, - his bubbles are currently leaving the water system;

- crackling and "shooting" - the winding has "broken through" onto the motor housing or a foreign object has entered the pump;

- buzz - a sign of a short-circuited turn in the motor winding.

It is required to immediately turn off the power and water supply, remove water from the machine, remove the laundry and disassemble the unit.The pump mechanism is often non-separable, but you can pre-ring the motor winding. And also check if the drainage channels are not clogged with debris, dirt or small objects.

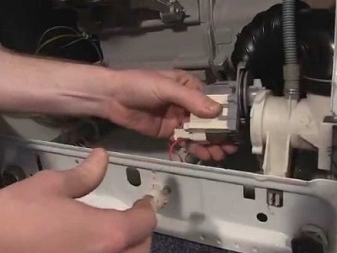

Repair and replacement of the pump

Before proceeding with the replacement of the pump, it is necessary to properly disassemble the MCA in order to get and comprehensively diagnose it.

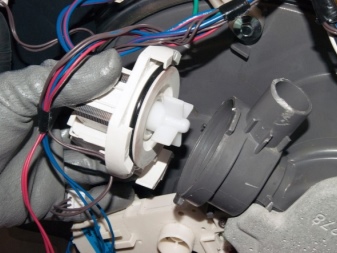

To remove the pump through the bottom of the washing machine, do the following:

- unscrew the bolts holding the bottom cover;

- unscrew the side screw;

- substitute a basin or bucket to collect water and unscrew the filter with turning movements, excess water will drain into the container;

- turn the pump counterclockwise, pull it out of the machine through the lower bay, where the lower wall was;

- disconnect the wires that fit the pump and the clamps holding the pump.

If the pump is removed through the back bay, do the following:

- remove the back wall, disconnect the drain pipe (corrugation or hose);

- disconnect the wires suitable for the terminals;

- unscrew the pump and separate the pipes from it.

If the pump is removed from the front, do the following:

- pull out and remove the detergent and descaler tray;

- unscrew the bolt under the tray, open the filter flap;

- remove one more bolt and dismantle the lower part of the front panel;

- remove the last two bolts, pull out the hatch gasket and its blocker;

- pry the latches and remove the remaining section of the front of the CMA housing;

- remove the bolt located under it and move the container for collecting waste water;

- remove the pipe and clamp and drain the remaining liquid from the tank.

You have full access to the drain pump. Repair and diagnostics go side by side here.

- Determine how much the pump began to make noise during the pumping process.

- Check if how much the filter and drain hose are clogged. The filter is easy to clean with almost no tools. The hose connects to any tap in the house and is flushed with water.

- You can set the machine to rinse the laundry.... The pump is fully operational when water is poured and drained at the capacity declared in the instructions. If malfunctions are detected, check the rotation of the propeller.

- To check the propeller, unscrew and remove the filter... Rotate the propeller manually. When slowing down and "sticking", check for dirt, debris and foreign objects to prevent it from spinning.

Remove anything that slows down the impeller.

In the absence of the above interfering factors, suspicion falls not on the pump, but on the electronics. Due to its failures, the machine is randomly turned off. Here you cannot do without masters. Before buying a new pump, check with your sales consultant which of the available devices is suitable for this AGR. After purchasing the pump, disconnect the washing machine from the water and power supply. To replace the drain pump, do the following:

- disassemble the CMA in one of the above ways, checking with the consumer's instructions;

- remove the bolts holding the pump mechanism, disconnect the wires suitable for the motor;

- remove the outlet hose and inlet pipe, drain the water remaining from the end (or interruption) of the last wash;

- remove the pump, replace it with a new one (exactly the same).

Reconnect the electronics and start the CMA.

If the new pump also works unsatisfactorily, you need to replace the electronic control unit.

Helpful hints

The pump motor, like the main motor that rotates the drum, needs periodic (at least once every six months or a year) cleaning and lubrication of the bearings. If a whistling squeak appears when the impeller rotates, it is a sure sign that the ball bearings need to be lubricated.

- Use the powder recommended specifically for automatic washing machines... It is undesirable to use a composition for hand washing and activator-type machines.

- Install an additional water filter in front of the machine - it is impossible for grains of sand, rust and dirt to get inside the unit, otherwise the pump will eventually clog up.

- Periodically clean the drain filter.

- Make sure the garment does not contain loose or loose threads.... If the fabric begins to unravel, it is better to wash such a thing by hand, or even better - to replace it with a new one.

- Clean layers of dirt from clothingif they appeared.

- Do not allow animal wool or feathers to enter the drain when washing. If, for example, a cat often rested on the rug by the front door, and you want to wash this rug, first chicken out, collect the wool from it with a brush, by knocking out or using a powerful vacuum cleaner.

- Do not overload the machine with laundry or load it to the limit. If the SMA can handle 7 kg, load 5… 6.

Observing all these recommendations, you will extend the life of both the pump and the entire unit as a whole.

Conclusion

It is not difficult to clean or change the pump. A washing machine is no more complicated than a vacuum cleaner or an automatic dishwasher. There is even a way out of an emergency situation. Help the home master and instructions, and photo, video on the Internet on this topic.

You can find out how to replace the pump in your LG washing machine below.

The comment was sent successfully.