Overview of machines for the manufacture of blocks and the nuances of work

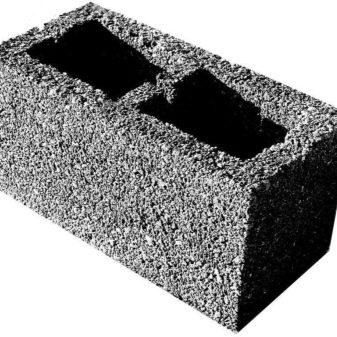

Cinder block is a material in demand in construction, with the help of which various buildings and structures are erected. It is made from cement and aggregates to achieve high strength and extended service life. To speed up the production of cinder blocks and other types of artificial stones, special equipment - a machine tool - allows. It is worth considering in more detail the features of such installations.

general description

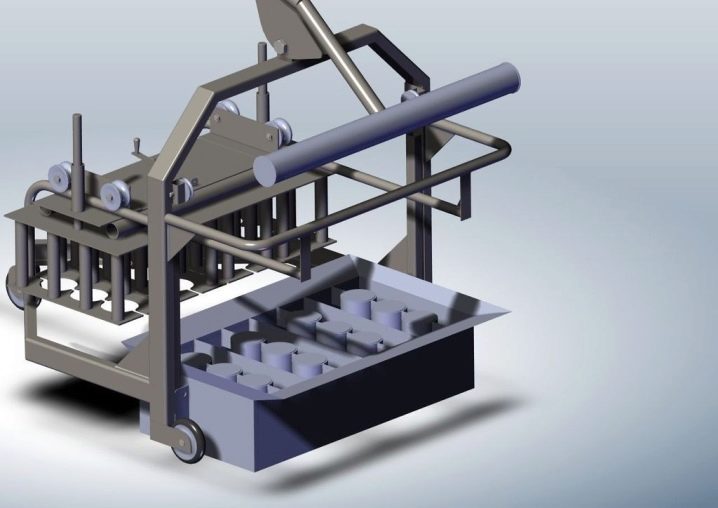

Vibrating machine for the production of building blocks - a special installation designed to automate the procedure for the manufacture of artificial material, which will subsequently be used for the construction of buildings and structures. The design of a standard machine includes:

- frame;

- press die;

- void former;

- electric type motor.

Press die usually made of sheet metal, the surface of which is additionally treated with anti-corrosion compounds. The void former is also a cone-shaped form. This design simplifies the operation of the equipment and allows you to easily remove the mold from the block.

Manufacturers use powerful motors, which are responsible for starting large equipment and its continuous operation. Block machines are suitable for installation both in production and in private workshops. With their help, in addition to cinder blocks, it will be possible to form:

- expanded clay block;

- heat block;

- polystyrene concrete;

- arbolite;

- concrete block for the foundation;

- paving slabs;

- parking tile.

And this is not a complete list of possible materials available for production on a conventional machine.

A block making machine is a special type of equipment necessary for organizing an efficient and trouble-free construction process.

Views

Block making machines differ in size, design, characteristics and other parameters. Manufacturers regularly release new models, which makes it necessary to organize a certain classification of equipment.

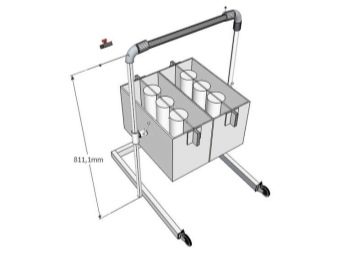

Manual

The simplest type of machine that is suitable for home use. Interestingly, it is also the most extensive category with a large selection of devices from different manufacturers. Advantages of mini machines:

- compact size;

- the convenience of use;

- budget price.

Small dimensions make it possible to install equipment even on a small area and simplify transportation. The average power of the engine used in the construction of such machines is 200 watts. Up to 25 units of hollow blocks can be made in an hour.

The cost of a manual machine ranges from 5,500 to 8,000 rubles, so owners of small workshops can afford such an installation. There are also more expensive models equipped with dies for the production of blocks of different types.

The main advantage of a hand-held machine is that you can easily do it yourself. However, such installations will have low productivity and require a lot of time and effort to make blocks.

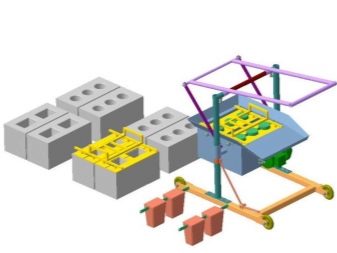

Semi-mechanized

Units for home and industrial use. The difference between semi-mechanized machines and manual machines is their impressive size, which will require a large installation site. The design includes:

- lever mechanism;

- matrix;

- frame;

- electric motor.

The matrix makes it possible to transport finished products to the floor, so machine tools need a lot of space to have where to move the blocks. The average price of equipment is 25,000-13,000 rubles, the exact cost is determined depending on the number of installed matrices. Such installations are capable of producing from 30 to 60 blocks per hour.

Increased power

Such equipment has high performance, for which it is appreciated in construction. The principle of operation is the same as for semi-mechanical models, the difference is a high power engine, which is installed in the structure. This decision made it possible to increase the output of products and speed up the process of making blocks.

Additional structural elements:

- frame;

- pressure cover;

- levers and mechanisms.

The average weight of the machine reaches 220 kg. The equipment is oversized and therefore requires large areas for placement. To organize the efficient operation of the installation, you will need access to a voltage of 380 V. The average price for a machine reaches 60 thousand rubles and may vary based on the configuration.

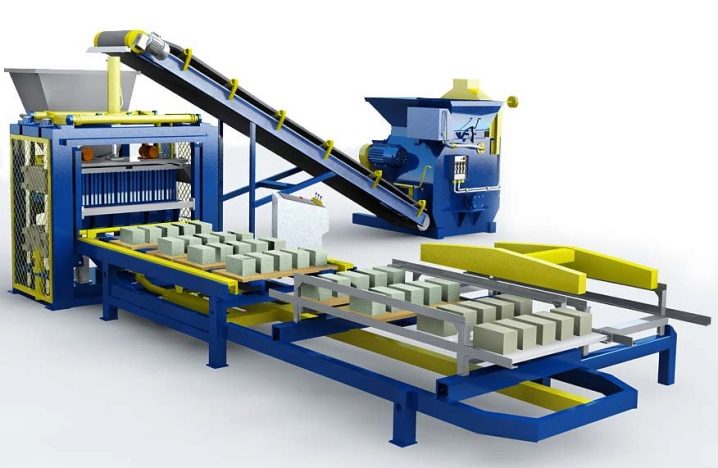

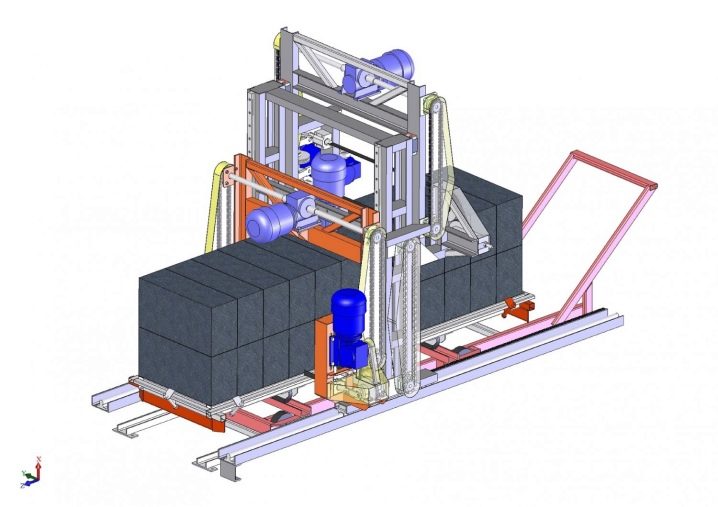

Automated

Additionally, they are divided into semi-automatic and fully automated machines. First, it is worth considering the features of the first subgroup. The design of semi-automatic machines can be equipped with different dies, the choice of which determines the type of materials produced. On a similar installation, you can make:

- cinder blocks;

- curbs;

- paving slabs;

- composite.

An important element of the machine is the clamping part, on which the productivity of the installation as a whole depends. Therefore, when choosing a model, you should pay attention to those in which the clamping part is reinforced.

Automated devices are the second subtype of machine tools, which are stationary equipment of high performance. The average price for such an installation reaches 400 thousand rubles. For the installation of machines, a separate area will be required, as well as a place where ready-made blocks will be stored.

Characteristics of automated machines:

- adjustment of production output depending on demand;

- the average volume of products is from 360 to 850 pieces;

- vibration compactor operation interval - 25 seconds;

- engine power - 5.2 kW;

- machine weight - 800 kg.

The equipment speeds up the block production process several times, therefore it is used mainly in enterprises where the production of large volumes of building materials is required. The operating principle of the machine is quite simple. The design contains a hopper, where the operator pours the solution, which immediately moves into the mold through the dispenser provided by the scheme.

Automated machines are used to obtain high quality building materials that meet the characteristics established by state standards. The release of defective products is impossible, which makes the equipment attractive for small and medium-sized businesses.

At least 3 people should monitor and regulate the work of oversized equipment: an operator and 2 workers. The first one controls the process of making blocks, the rest take out semi-finished products for drying.

Popular manufacturers

The construction equipment market is represented by a wide variety of block making machines. Among the popular manufacturers, it is worth noting the following companies:

- Delay Bloki;

- Asia Contract LLC;

- LLC Siberian Monolith;

- LLC "Stanline";

- LLC "Stroytekhnologii".

Manufacturers regularly update and improve their assortment, offering high-quality equipment with high performance. The presence of a wide range of machines for the manufacture of blocks sometimes leads to a stupor, and it is not immediately possible to choose the right model. Therefore, when purchasing a unit, it is worth considering the following criteria.

- Buyer's needs. This is the first thing to look for in order to narrow your search.The size of the machine, the characteristics and the way of control will depend on the preferences. For example, for a home, the best solution would be a small manual installation that can fit in a small room.

- Engine power. The performance of the equipment directly depends on it. The higher the score, the better. But at the same time, the maximum power units are suitable for use in workshops or in the enterprise.

- Number of matrices... Determine the number of blocks that the machine will be able to produce in an hour.

- Dimensions and weight. For home use, it is worth purchasing compact units that do not require much space. Productions where work with large volumes of materials takes place requires large-scale units.

- Price... It is not recommended to immediately look only at expensive models. Budget options can also be useful if professional use of the machine is not planned.

- Equipment... The functionality of the installation depends on this. The more components, the more tasks the equipment will be able to perform.

- Design... Here it is worth paying attention to the material of the elements from which the machine is assembled. The service life and accuracy of the equipment tasks depend on this.

Additionally, it is recommended to look at the manufacturer and read reviews. Taking these factors into account will help to select equipment with characteristics that meet the user's needs.

Features of operation

The work of machines for the production of cinder block is carried out according to a single principle:

- the form provided for by the design is poured with a solution of a semi-liquid consistencyso that the block afterwards gives a slight shrinkage, and then cover it with a lid on top;

- within 10-15 seconds the electric motor is running, providing the necessary vibration compaction of the mixture;

- molds are removed using levers or manuallywhen it comes to compact machines and leave the finished blocks in place.

After a certain period established by the standards, the blocks are moved to a warehouse or directly to a construction site. Working with block machines requires a responsible approach and compliance with safety regulations.

- It is recommended to carefully check the integrity of the installation before starting the machine. In the presence of defects, breakdowns or serious malfunctions, it is worth postponing the use of the equipment for a while and asking for repair.

- Before making the blocks, you should carefully study the instructions provided with the kit. It describes in detail the nuances of the launch of technology and the manufacture of building materials.

- There is a risk of injury when using the machine. To prevent this from happening, you need to take care of personal protective equipment, gloves.

- If the machine starts making suspicious sounds during block production, it is worth stopping the process and diagnosing the equipment.

The block making machine is a popular piece of equipment in any construction site or production workshop. The presence of such an installation provides the possibility of continuous stamping of high quality building materials.

The comment was sent successfully.