Overview of jigsaw machines and their selection

A jigsaw is a special device with which it is possible to perform any type of sawing: straight, angular and longitudinal. Such units are used for processing decorative elements, jigsaws are in demand both in home workshops and in carpentry.

Peculiarities

The main purpose of a jigsaw is the formation of curved contours by sawing or cutting. With the help of such a tool, sheet blanks and wood canvases are processed, which will become elements of furniture structures, musical instruments and other products. Standard jigsaw designs include:

-

work surface - table;

-

electric drive;

-

crank mechanism;

-

cutting element - saw;

-

tension knot;

-

accessories.

The latter represent additional equipment of equipment to simplify the work and improve their quality.

Description of species

Manufacturers produce a wide range of jigsaws, which differ in design, operation, characteristics and appearance. It is worth considering several standard types, for example, pinless or other models.

Manual

The shape of the instrument is a curly frame that resembles a horseshoe from a distance. The ends of the jigsaw are equipped with blade and handle attachment points, which makes the use of the tool convenient. Handheld devices are suitable for home use, designed for processing plywood and plastic sheets. Among the advantages are:

-

availability;

-

ease of use;

-

long service life.

The disadvantage is the impossibility of processing large volumes.

Domestic

Standard motorized tool with high working speed. Suitable for use in both a home workshop and a large enterprise. The advantages of the tool include:

-

long service life;

-

the convenience of use;

-

reliable design.

Some models are equipped with batteries, which eliminates the need to connect to the network and provides autonomous operation. Among the disadvantages is the impossibility of long-term work. Manufacturers use medium power motors, which means they have to constantly interrupt workpieces to prevent overheating of the tool.

Professional

A jigsaw with a battery and a reliable design, in demand in production. Provides a high speed of processing products, suitable for processing large volumes of wood products. The advantages include:

-

high quality components;

-

high precision cutting;

-

long-term work;

-

powerful battery.

The only drawback is the price.

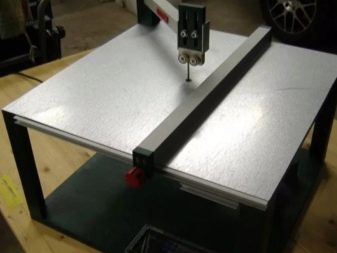

Desktop

The peculiarity of this group of jigsaws is safe and comfortable work. The tool provides high cutting accuracy and is used for processing wood sheets. Pros:

-

reliable fixation of the workpiece;

-

reciprocating movement of the working body;

-

powerful engine;

-

work with thick sheets.

The minus of the tool is at a high price. However, all models of this group fully justify it.

Industrial

It is not hard to guess that vibration machines in this category are suitable for use in production. Such devices usually operate on a high voltage network, which increases the processing speed and allows the formation of a large amount of material. Pros:

-

high technical characteristics;

-

a large set of accessories;

-

Control block.

The latter allows you to adjust the parameters of the installation.

Top Models

The construction tools market offers a wide range of jigsaws of different types and characteristics. It can be difficult for a buyer to immediately determine which tool is right for him. To make the search quick, and find the pinless model, a rating was formed from the top 3 best jigsaws.

Proxxon DSH

Standard stationary equipment for processing wood, plastic and metal products. The design includes a frame assembled from durable cast iron, which ensures a long component life and resistance to external influences. The pluses include:

-

aluminum table;

-

speed control;

-

blowing system;

-

dust extraction.

And also the user can adjust the slope and stroke frequency of the components.

Einhell TC-SS 405 E

Artistic machine for work in production, designed for processing materials from:

-

wood;

-

plastic;

-

gypsum.

The user can adjust the slope of the work surface. The design of the machine includes an adapter where you can connect a vacuum cleaner so that the work is not too dusty. Component structures are highly durable and protected from external influences. Pros:

-

ease of use;

-

work with heavy loads;

-

blowing system;

-

protective screen.

And also the manufacturer provides a system for removing shavings and dust.

"Craton WMSS-11-02"

One of the best jigsaw electric CNC machines, which is included in the group of budget devices. Among the features of the tool are:

-

speed control;

-

long service life;

-

protective screen.

The device practically does not heat up during operation, which makes it possible for long-term use.

Components

The jigsaw is considered a versatile and functional tool. The latter is provided by additional units and parts that are part of the structure. The main type of accessories for any machine is saws - cutting tools.

To equip the machine with the optimal saw, you must first study the configuration of the selected model. To do this, it is recommended to clarify the principle of operation of the tool, equipment and instructions for use. A competent approach to the selection of consumables will allow you to immediately choose the right option.

Manufacturers produce different types of wood saws, which differ in the manufacturing method, material, characteristics and service life. That's why before buying, you should first decide on the characteristics that the purchased model will subsequently correspond to.

T-shank files are especially popular. Cutting tools are used in many machines by well-known manufacturers.

Criterias of choice

Choosing a jigsaw requires a careful approach. When buying, it is important to consider several criteria that will help you choose a reliable and durable model that meets the requirements of users.

Table top

The working surface of the machine can be a cast or stamped plate. The first option is preferable, which is additionally equipped with pivoting mechanisms for rotating the fixed workpiece and changing the angle of inclination.

Additionally, you should pay attention to the size of the work surface. The larger the area, the wider the functionality, and the more convenient the operation of the machine. The average length of the saw should be up to 40 cm, which is enough to secure even a large part.

Engine

It is important to take into account the power and type of power unit that is installed in the structure. These parameters will determine how thick the workpiece will be able to process the device. The average engine power for high-quality work should not be lower than 200 watts.

If you plan to process steel profiles using a jigsaw, then you should give preference to models with an engine with a power of 250 W and above. Most manufacturers use the following types of motors.

-

Brushless. Differs in high power indicators.

-

Brush. A feature of the power unit is a smooth change in the frequency of the file stroke.

The higher the power, the more noticeable the potential of the machine. However, the final decision rests with the user, who should consider the location and duration of the equipment use.

Blank

Particular attention should be paid to the thickness of the part. Most compact machines are designed for sheet metal up to 50 mm thick. If you need to cut thicker workpieces, then professional models should be preferred.

Fixing the tiles

The workpiece is fastened to a jigsaw machine using a pin file or a double-sided clamp equipped with a screw. Most often, such fixation does not affect the quality of the cut, but there are still differences.

There are also pinless models on the market for construction tools and equipment. The installation of such units will take a lot of time, since it is far from always possible to find a place where the machine fits perfectly.

Vertical stroke

Home models are equipped with a maximum travel of 15 mm. For professional models, the indicator reaches 19 mm. The parameter is considered one of the most important, as it determines the ability to remove sawdust from the workpiece and increases the service life of the blades.

Frequency of movements

On average, the indicator ranges from 400 to 2250 units. Lowest speed is an option for light alloy materials that can be easily cut. The maximum value is more suitable for handling hard or brittle materials. Additionally, it is worth paying attention to the method of frequency adjustment: it can be stepped or variable.

Noise level

The quality of the work performed depends on how noisy the equipment works. It is worth noting that not all jigsaw machines hum or vibrate a lot in the process. Preference should be given to less noisy models - these are mostly compact devices.

Functional

Modern jigsaw machines have a wide range of functions. Manufacturers equip devices with various systems: backlights, protective screens and other options that facilitate work and allow you to achieve high quality cutting.

How to do it yourself?

If you don't have a jigsaw at hand, you can make one yourself. Several options are worth considering in more detail.

Simple

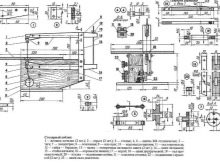

A standard machine from available tools does not require much time, effort and financial investment. First of all, it is necessary to find drawings and diagrams to make it easier to design and assemble the tool in the future. Next steps.

-

Manufacturing of the bed. You need to do it yourself from plywood 12 mm thick. And you can also use textolite and thick plastic.

-

Installation of the rocking chair. It must be located on the other side of the bed. The design of the rocker must be additionally equipped with an eccentric. The elements are connected to each other by a metal plate equipped with bush bearings.

-

Installing the intermediate shaft. Here you will need to prepare the bearings in advance. A double-ribbed steel pulley is also put on the shaft, and the connection is secured with bolts.

-

Making holes. They are made on an eccentric flange.

-

File attachment. One of the important stages, which should be done carefully. Insert plates are rigidly fixed and tightened with Grover screws and washers.

The last element is the installation of a rocker stand to a homemade mini-machine, which must be metal, since the support has a large number of loads.

From the pipe of the vacuum cleaner

This is more of an addition and, according to the reviews on the forums, not always effective. It is possible to use a vacuum cleaner pipe to remove cut grass, but it is not a fact that the equipment will work.

See the master class below.

From a jigsaw

A simple way to create a jigsaw using a frame. An electric tool is mounted to it, installing it in a certain direction, after which they begin to carry out the necessary work. Many people consider a jigsaw from a jigsaw to be the most budgetary option.

Operating rules

Working with any kind of jigsaw requires safety precautions. Before starting work, it is important to make sure of the reliability of the design of the tool, as well as to use personal protective equipment: gloves, an apron, glasses. Additionally, you should carefully study the instructions, which spell out the nuances of using the device.

The comment was sent successfully.