All about band saws

A band saw is a tool designed for sawing and cutting wood or metal. The working unit in the machine is a closed band saw. Its belt is stretched over the pulleys and in working condition is in continuous motion.

Peculiarities

Bandsaws today are modern designs, somewhat different from their ancestors that appeared in the 19th century. Bimetallic rotating sawing bands are driven by a special belt stretched over a couple of pulleys of different diameters. To determine the technical parameters of the device, the following values are used:

- machine weight;

- saw band length;

- parameters of the working surface of the structure;

- power - household units 500-720 W, industrial up to 3 kW;

- electrical voltage - for household models 220 V, for industrial models they use a three-phase 330 V network;

- cutting depth - household options are able to cut through a thickness of up to 0.15 m, production up to 1 meter;

- cutting width - determined by the size of the gap from the tape to the rack, from 350 to 1250 mm.

The closed saw band itself has the following characteristics:

- height, length, thickness;

- setting, sharpening of teeth and other parameters.

The design of the machine looks like this:

- the pulleys are secured to the strong frame of the saw frame;

- one of the pulleys is driven, supplying kinetic energy to the band saw, thereby giving it a rotational motion.

After energizing, the drive pulley drives the saw band. The tension pulley adjusts the tension and pressure of the saw. After that, the material to be processed is fed using the frame. Even pressure on metal or wood ensures a perfectly straight cut at an acute angle of 60ºC.

Views

Bandsaws are manufactured in two versions: for wood or metal processing.

By wood

The purpose of woodworking machines is to work with lumber. Such designs have found application not only in industrial areas, but also in everyday life. A machine of this type is capable of precise cutting of boards up to 40 cm thick, produces a minimum amount of waste, and also:

- cutting on such a machine gives an almost perfect cut that does not require additional processing;

- machines of this type are capable of performing curved cutting of material;

- compactness - the units occupy a small area, which allows their use at home and in small workshops.

Bandsaws operate relatively quietly and do not generate much noise in the surrounding area. For their operation, you can use rooms with conventional noise insulation.

For metal

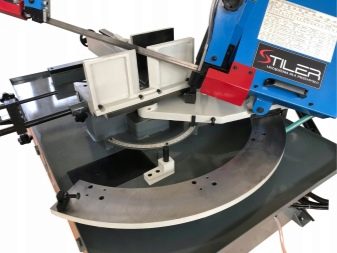

This band saw design is designed for metal processing and cutting, and it is also multifunctional. The equipment is capable of cutting both non-ferrous and ferrous metals, both steel and cast iron, as well as hard alloys: nickel, titanium and others. In addition to the main task, such a unit also replaces the woodworking modification, and also easily cuts plastic and foam. Advantages of metal band saw:

- the design provides variability of operation - straight and curved sawing;

- perfectly straight cut and minimum waste;

- compactness, minimum decibels in active mode;

- a wide range of models and a large selection of manufacturers.

Minimum noise performance and the possibility of purchasing a machine with small dimensions allow the device to be used in a private area, as well as in small businesses with limited production areas.

Manufacturers also offer 3 main types of bandsaw machines, which allows you to provide all areas of human production. Design developments prudently cover private and industrial needs.

-

Household - the design is designed for use in small home workshops, has a very modest size, operates from 220 V. A household sawing machine can be manual, automatic, desktop (installation on a workbench or table). Screws are used as fasteners.

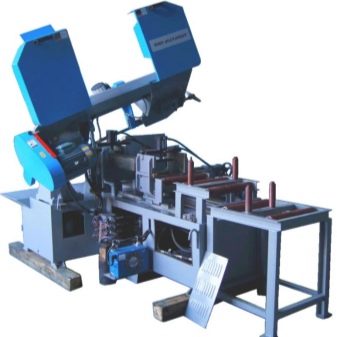

- Semi-professional machines used for cutting thinner material: up to 20 cm, popular in small workshops.

- Professional modification. This type of band saw machines has a large weight and impressive dimensions, requires a three-phase power supply, the installation is carried out only in a floor-standing version. Structures work with material with a thickness of 30 cm.

Bandsaws for metal and wood help to perform certain types of work in certain methods of processing wood and metals in various industries. There are modifications: cutting, dividing, carpentry and others.

Console

Devices of this type are equipped with a mobile frame, which allows you to raise and lower it, and a stationary bed. The console version is suitable for cutting and sawing small workpieces.

Column

Column manufacturers produce two types: one-column and two-column, otherwise - single-column and two-column machines. On single-column devices, the frame moves along one column, cutting medium-sized parts with different angles. The two-column frame moves along two columns, respectively. They are used to work with difficult-to-machine materials.

Vertical

This type is equipped with a vertical frame and the market offers two types of structures: small-, large-sized options. If in the small-sized version the saw is the only moving mechanism, then in the large-sized version not only the saw band is active: the workpiece can be moved on the work table in a given plane.

Portal

The modification is distinguished by design features in the form of a static desktop. The saw band moves along the table and cuts large-sized workpieces that are difficult to process.

Horizontal

This type of machine is equipped with a horizontal saw frame. The main purpose is the processing of large-sized hardwood. The above are the main modifications of band saw machines, but these are far from all the technical characteristics. There are units:

- manual, when the adjustment of the entire process is carried out manually or by hydraulic loading (the process is controlled by automation based on hydraulics);

- automatic - all cycles are carried out in automatic mode;

- semi-automatic - this option provides for the operation of the machine in manual and automatic modes.

The choice of modification depends only on the goals of the future owner and his capabilities.

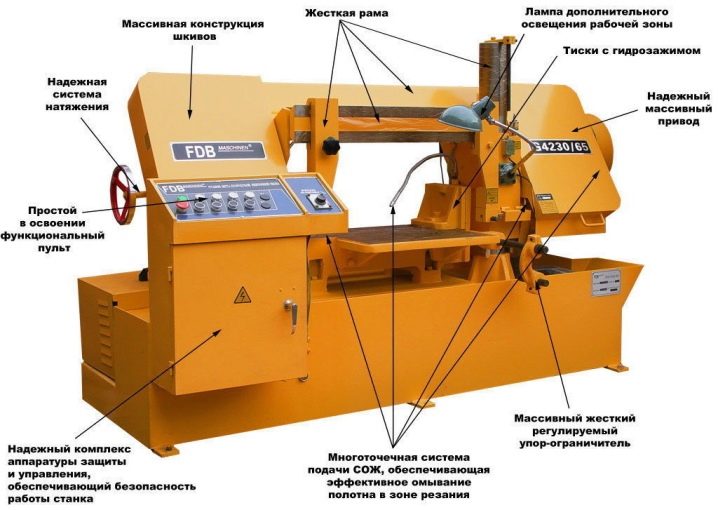

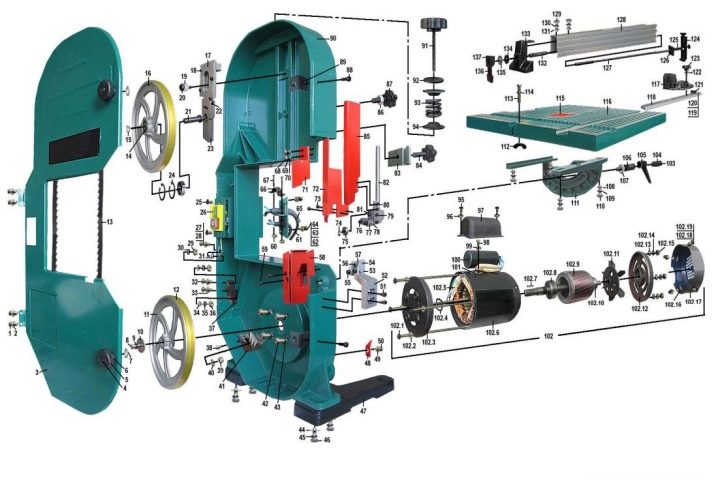

Components

A band saw machine consists of a fairly impressive number of spare parts, small and large parts. The main units that ensure the principle of the band saw mechanism:

- bed, electric motor;

- set of pulleys, belt drive;

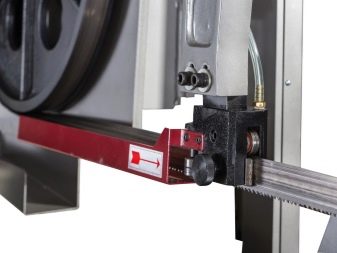

- saw band, brake assembly, guide elements;

- saw blade cleaning brushes;

- roller conveyor (conveyor belt).

The most powerful is considered to be the horizontal modification.It is this option that is applicable in the sawmill for processing frozen wood and hardwood, such as larch, oak, boxwood, hornbeam, and so on.

Top Models

World manufacturers offer many models of various modifications - the market is provided with such a product more than enough. The choice fully satisfies any needs of the buyer. Bandsaws for cutting wood.

-

Metabo bas 261 precision. The machine for working with wood provides high quality sawing. The swivel-inclined bed is made of cast iron, its modification allows for an inclined cut. Noise indicators are much lower than normal, vibration is weak, replacement of saw and conveyor belts is possible with maximum accessibility and speed. The level of comfort during operation is increased by the presence of an LED luminaire with a spot lighting location. It is possible to connect a vacuum cleaner to the machine for cleaning the working surface.

- Jet jwbs 9x. The model has a low price, but it shows excellent performance. The design is easy to manage, maintain, operate. The belt drive ensures the lowest vibration and noise levels. The machine works with workpieces up to 2 cm thick, it is possible to adjust the cut, a lamp, a graduated scale for determining the cutting angle. The disadvantage is the low power of the unit, but it performs its functions flawlessly.

- Metabo bas 318 precision wnb. The machine is designed for cutting wood, the design provides 2 speeds: 410 and 880 meters per minute. The powerful motor makes it easy to handle even hard rock, the feed movement is smooth, and the noise and vibration levels are relatively low. The device is provided with protection against accidental restart, a container for collecting waste, stops with double clamps, graduated and metric scales, precise guides, LED light. The design provides for an easy and quick change of the saw band.

- Einhell tc sb 200. The desktop version of the band saw is an inexpensive machine of small dimensions, which makes it possible to use the model in a private household. You can install the device on a table or workbench. At the same time, the device has a powerful motor, a pusher, a stabilizer for uniform vibration distribution, and a corrosion-resistant housing. The machine is capable of making workpieces of any shape.

Machine tools for working with metal blanks.

LPS 8535 00-01 RE (without turntable). Two-column console machine made in Russia for working with forging and rolling of ferrous and non-ferrous metals. It is provided with a hydraulic drive, an automatic waste disposal unit and a removable container, asynchronous motors, a control panel on a separate surface, automatic and manual operating modes.

Fmb OLIMPUS 3 + VHZ. The machine with two stands, works with workpieces up to 51 cm in diameter, a complex section profile up to 45 cm.Equipped with hydraulics for tensioning the frame and the saw band, a frequency converter for controlling the motor, a sensor that responds to saw breakage, a cutting angle indicator. A complex unit increases the level of labor intensity when replacing the saw blade with other characteristics: standard size, shape and pitch of the teeth. For this procedure, you will have to use accurate calculations, in which it is necessary to take into account the performance characteristics of the saw, as well as the features of the workpieces.

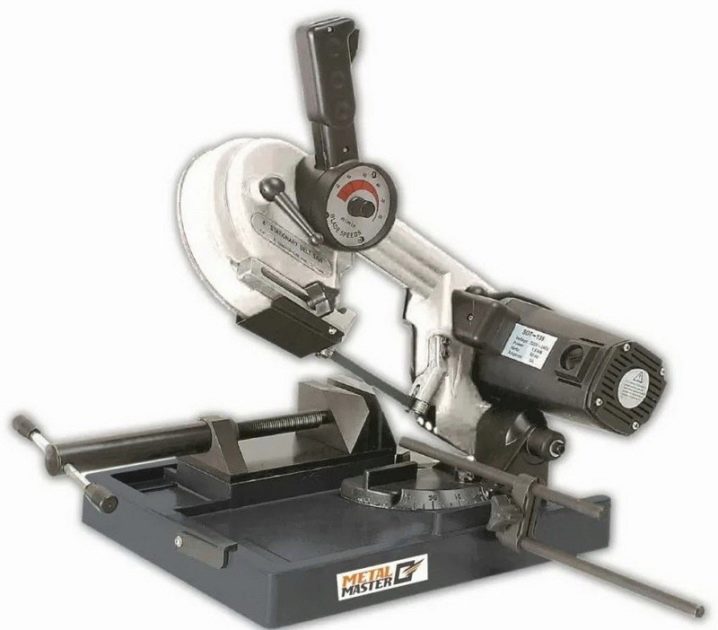

"Enkor Corvette 422". Mobile design with 3 operating speeds for the saw band and manual control. By changing the position of the vice, the cutting angle is changed. The belt reduction gearbox provides a worm gear transmission of rotation to the drive pulley. The engine stop is ensured by a limit switch when the working console is fully lowered, a magnetic switch guarantees the impossibility of spontaneous start when the voltage drops. The machine is used at home and in small workshops.

Blacksmith S13.11. The budget table-top machine is equipped with a brush motor, manual control of the cutting angle and a working console located on the support platform. The guide assemblies are equipped with five bearings, the balance of the console is ensured by an adjustable return spring. The disadvantage is an excess of silumin alloy in the structure itself, the absence of coolant.

Proma PPS-270THP. The stationary type machine is equipped with a control panel located on a separate surface, a swivel console, a working range from 45 to 60 degrees of an angle of inclination and a radial scale. The rotary switch adjusts the speed of the saw band. The machine has a hydraulic load, an indicator of the tension force of the blade, a hydraulic cylinder shutdown and a two-way coolant supply system are provided. The disadvantages include the complex adjustment of the same feed and the bed, whose rolled frame is covered with sheet metal.

The machines of the Russian brand PEGAS-GONDA s are very popular. r. o. The company has taken care of a high level of warranty and post-warranty service. Band sawing machines from Bomar and Belmash are not inferior to it in terms of performance. The design of the units ensures their high productivity, durability of operation, comfort in maintenance and work.

Usage

Working on bandsaw machines is associated with an increased risk of injury, therefore, it is necessary to strictly observe safety precautions. Its rules are written using many years of experience and statistics of accidents, each point is mandatory. In addition, the sequence of actions during the operation of the unit is important.

- Before starting work, carry out a preliminary adjustment of the angle of inclination and depth of cut, as well as the tension force of the band.

- Then it is necessary to fix the workpiece to be processed in order to minimize the level of vibration and to ensure the accuracy of the cut.

- Optimal lighting levels are critical to work efficiency. Experts recommend giving preference to LED lamps.

- Installation of small-sized units is permissible on workbenches and tables, while large-sized professional machines are installed in a floor-standing version.

- To obtain a curved cut, use tools for fixing and feeding the material, for a straight cut - a mobile stop.

- Saw blades, band blades, belt drive must be periodically replaced, and all moving parts must be inspected and lubricated regularly.

- The saw blade should be positioned as close as possible to the workpiece.

- During work, you must use personal protective equipment: respirators, goggles, gloves.

For information on how to choose the right band saw machine, see the next video.

At the end of the work, the machine is disconnected from the network. Before starting operation, it is necessary to undergo a safety briefing. Possession of the appropriate qualifications to operate a band saw is a must.

The comment was sent successfully.