What are planing machines and how to choose them?

Woodworking requires a variety of machines, each of which will perform the necessary actions and functions. One of these tools is the planer products that are part of every logging company. These machines are extremely versatile and therefore popular with consumers.

What it is?

As already mentioned, many types of machine tools are used in the manufacture of wood products. Therefore, a common buyer often has questions about what planing machines are, what are their features and purpose.

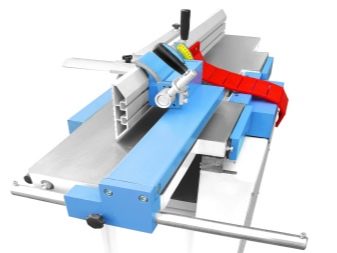

Jointing is one of the stages of wood processing. The difference from thicknessing or planing is that in this process, the main elements are workpieces of great length - boards and other large materials. In this regard, the specification is such that it requires the machine to have a fairly long bed and a work table with appropriate fasteners and clamps.

As for the cutting materials, they are very similar to those used on other machines.

The planing tool also has its own classification, and in accordance with technical documents they are referred to as longitudinal milling machines, that is, their principle of operation is that the workpiece itself moves relative to the cutting tool and other important tabletop units of the device. Wherein planing machines are mostly intended for roughing, since they only do superficial removal of material from the board. But it is worth noting that everything also depends on the specific model, its configuration and the capabilities provided by the design and functionality.

Views

Equally important is the difference in the characteristics of planing machines in accordance with their specific differences. In this regard, this type of product is simple - they are divided into one-sided and two-sided.

Unilateral

They are usually used in private small home workshops, as well as in primary and medium-sized enterprises, where there is no talk of large-scale production. Single-sided planer units can process boards, beams and other wood building materials up to 1.5 meters long. Due to technical simplicity, most of these models have only manual feed of workpieces, the speed of which does not exceed 10 m / min.

And also, among other features, it can be distinguished that during the passage only one side is processed, so you will have to shift the wood and carry out another removal.

Only one operator can operate and maintain such a machine. Naturally, the advantages of one-sided machines include a low price and ease of use. But if time and production volumes are extremely important to you, then double-sided machines will be a more suitable option.

Double-sided

Based on the name, we can conclude that they can join the workpiece from two sides at once, while both in the same and different variations, depending on the nozzle acting as a cutting element.

Most modern double-sided machines have a built-in automatic feed, which makes it easier for users to operate and makes the process more productive. Another feature is that for these models there is a wide variety of control systems, which can be either partially or completely electronic. Also, double-sided planing machines from well-known manufacturers can be upgraded by increasing the working space or providing additional units if the manufactured products require a narrower specification.

Some craftsmen distinguish machines depending on the way of doing the work - circular-planing and planing-jointing. But for the most part, this applies to professional expensive models, where several operations can be performed simultaneously on one workpiece.

Top manufacturers

To more accurately understand what the variety of units is, it is worth compiling a rating of companies that produce machine tools.

Often, a Russian buyer turns his attention to the European market, where there are many machine tool companies. Perhaps, one of the most famous is the Bulgarian Stomana. The company's products are extremely wide and include equipment for processing both wood and metal. At the moment, among the planing machines, there are 3 models from the DMA series, two of which are analogous to each other.

These units are designed with a solid cast iron base for strength and vibration reduction.

It is worth noting that the Bulgarian manufacturer has equipped each model with the ability to change the angle of the cutting tool. This means that the user has the ability to set the desired position of the saw blade, and machine workpieces in a wider range. For safety reasons, the machines are equipped with a cutterblock fuse. The maximum thickness of the removed layer in one pass is from 5 to 8 mm. Working width 410 or 530 mm, which is indicated in the product name. The rotations of the knife shaft are 4500-4700 per minute, each machine is equipped with all the necessary measuring devices and tools, with which you can independently set the desired parameters for sawing.

Stomana also offers its customers additional types of complete sets, which include expanded tools and improved technical characteristics. Most of them are aimed at increasing the productivity of units. One of the main advantages of the equipment of this company is its low cost in the presence of decent characteristics.

Another well-known European manufacturer is Griggio. This Italian brand has been cooperating with domestic companies for a long time and has its own representative office. At the moment, the range of planing machines includes two units that can be classified as professional. High performance of the equipment is achieved thanks to reliable 4 kW motors. The dimensions are 530x3000 mm, the dimensions of the working table reach 540x260 mm.

At the design stage of the machine tools, the manufacturer decided to make the accuracy indicator decisive for the products, therefore planing units Griggio are known primarily for the ability to finely work the wood, which makes them truly special. While most conventional companies make roughing machines, the Italian firm decided to take it a step further and equipped the models with the capabilities and functionality that allows technology to do more than its competitors can do.

In addition to the existing planer products, Griggio has a number of archived models that can be found in some production facilities. Their functionality is also wide, but not comparable with the existing units, since the introduction of new technologies in the company takes place on an ongoing basis.

Among the American manufacturers of this type of machine tools, the world famous JET company can be distinguished. Many years of experience and the presence of factories in different parts of the world allow the company to supply many consumers with its products - from small private workshops to the largest industrial enterprises, where large volumes of products are combined with high quality standards. The wide model range of the company can be conditionally divided into two types - amateur and semi-professional JET and multifunctional Powermatic.

The first ones have a very different price range and are designed for works of medium and high complexity. Performance, workspace, equipment and many other aspects depend purely on the model, because the company tries to manufacture machines not according to a template, but in accordance with the technologies used and the intended field of application. Powermatic is more expensive, but it is a versatile machine that can handle a wide range of tasks in the most challenging variations.

It is worth noting their rich configuration and many opportunities for upgrading through accessories and components.

If, in general, to summarize the results of the manufacturers, then, indeed, there are many reliable ones. Therefore, when choosing a technique, you should not get hung up on one company, you need to choose in accordance with other criteria, of which there are quite a few.

Components

Each manufacturer has an individual approach to the issue of components and accessories for their machines. Some firms equip their own products with only standard equipment, while all other items are sold separately. This approach has one significant advantage: the consumer can subsequently buy in addition what he will need in accordance with the production goals. On the other hand, when purchasing a professional machine for a decent price, you want it to have everything you need for variable operation, and there is not always a desire to incur additional costs.

Another group of companies does the opposite, and equips the planing units with a wide range of components, which includes a wide variety of components. - clamping parts, mounted tables to increase the area of the working surface, replaceable attachments in the form of knives. And also there may be guides and measuring instruments - rulers with serifs and a certain stroke. Some manufacturers, for example, JET, allow the consumer to choose a complete configuration, which will include not only individual spare parts, but also working units with their own technologies.

A potential buyer should pay attention to the question of the choice of components. Most of the well-known companies sell their own components, so it is better to purchase them directly from the company. It is advisable to do this in order not to face a situation when components purchased elsewhere are simply not suitable for jointing machines.

The conformity of the part with the unit is guaranteed only with the purchase of components from the same manufacturer.

As for the installation of accessories and other parts, this process should be carried out strictly in accordance with the documentation. It should be understood that independent changes in the design that are not provided for by the package may entail consequences in the form of a malfunction of the mechanisms or loss of efficiency of the unit. Therefore, be extremely careful when selecting components.

Nuances of choice

There are a lot of criteria for the selection of jointing machines. First of all, you need to decide on the main ones that make up a significant difference in the products. The consumer needs to match the required amount of work to be done with the type of machine in accordance with its performance. As mentioned earlier, if the machining volumes are small or inconsistent, then the choice of a single-sided machine is the best option. It is simple and does not require special operating conditions. In addition, they are cheaper, and the level of total costs will be lower.

A more interesting situation arises when the buyer has already decided to choose a double-sided planer for professional use. In this case, it is worth paying attention to specific technical characteristics. The first of these is the width of the table and the workpieces that can be fixed on it. This parameter is especially important for complex work where boards and beams of considerable dimensions are used.

The optimal performance is considered to be from 500 to 630 mm.

Another important characteristic is the design of the cutting tool. The shaft with fixed attachments can have from one to four knives. Naturally, the more, the better. This indicator directly affects how carefully and accurately the layer will be removed from the wood. It is also important to clarify that double-sided models have two such working units, which, together with the function of turning the workpiece by degrees, gives an excellent opportunity for variable jointing. But the more knives, the more time it will take to prepare the machine.

The cleanliness of processing and productivity also depend on the rotor of the device. It is desirable that the electric motor has a power of 5-5.5 kW. In addition, pay attention to the number of revolutions per minute. Typically, the average is in the range of 4,500 to 5,000.

Setup and operation

Another factor that must be observed for high-quality planing is the correct setting of the sawing machine. It includes several stages, and each should be disassembled separately. First of all, this is the control of parallelism and the preparation of cutting tools by means of fastening and sharpening, which can be carried out even at home using the appropriate tool.

The second stage is the complex adjustment of the table and guides. The positioning of the workpiece is extremely important, because precision in planing is one of the keys to successful work. If the package includes an extension for the table, then it is necessary to choose the correct ratio of these parts of the structure. The second step involves adjusting the guide ruler to the size of the thickness of the layer that will be removed from the wood.

The final step is purely technical, as the user needs to set the feed rate of the workpiece and adjust the feed mechanism. After completing all these steps, you can place the workpiece on the table and start starting the engine.

During processing, it is important to protect the user, and not to do those actions that are prohibited by the instructions.

Do not forget that after some time of operation you will need to sharpen the knives and carry out diagnostics. Check parallelism levels and distance between nodes and workpiece. A lot of chips remain on the machine during planing, so keep the workplace clean by connecting the pipe and chip suction. They are often included in the basic equipment of many manufacturers' models.

The comment was sent successfully.