Overview of furniture making machines

Furniture manufacturing is a popular business that is actively developing. Many businesses and stores sell a wide variety of products, including custom-made products. But not everyone thinks about what equipment is needed for this. But this is not one or even two machines, but a whole list of professional equipment.

Features of sawing machines

Sawing machines are one of the foundations of the woodworking business. They are represented by a variety of models in terms of functionality and working volume, therefore they can be used for the production of furniture at home or at large enterprises. By their design, these machines resemble devices with a circular saw, the main purpose of which is the primary processing of wood in size, depending on the desired result.

Usually, modern sawing machines have a gear train and powerful motors with a large number of revolutions to carry out large-scale jobs. Among the more expensive models, you can find specimens with elongated tables and additional guides, which make operation easier and more convenient, and the cutting process itself is more accurate.

The versatility of sawing equipment lies in the fact that it can process a variety of materials, such as chipboard, chipboard, MDF, solid wood and other raw materials used as the basis of upholstered furniture.

Among the modifications of such products, it is worth noting the presence of electronic control systems, various built-in storages, operation indicators, measuring instruments and much more, which manufacturers offer as separate options for improving technology in comparison with basic configurations.

Description of drilling models

This type of machine is necessary when furniture production includes options for the manufacture of cabinet products or products with shelves, compartments and other collapsible elements. The basis of the structure is represented by a work table, on which the workpiece is fastened by means of a vice. The main working units - the spindle and the motor - are located at the top of the equipment.

For switching the speed of the machine, the redirection of the belt pulleys is responsible. The design is very simple and versatile, and therefore is used by both amateurs and professionals. Among the varieties of drilling machines, it is worth highlighting table and floor options, and the latter are attached thanks to separate support legs. Adjustment of the drill movement occurs due to the movement of the handle. It can be presented both as several separate elements and as a solid wheel.

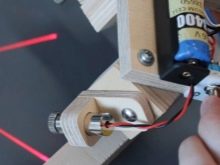

More advanced models are complete sets with laser pointers, the ability to quickly change drills without a key, as well as units with various functions to protect the engine from power surges.

The price range is very diverse and depends solely on the technical characteristics and the final configuration of the machine.

Cutting machines

Used for cutting sheet material in medium and large production. This equipment should be called universal, since, in addition to primary processing, it can be equipped with functionality to perform a wide range of tasks. Trimming units eliminate the formation of chips and other defects that can cause more serious damage to the workpiece.

The cutting part and its quality depend directly on the model. In professional cutting machines, the saw can rotate in different directions and be adjusted at the angles, thereby allowing you to do your job more variably. The frame of these products is made of reliable and durable materials, a guide system is provided. A good addition is the lengthening of the working table, the presence of a chip pump, as well as a protective casing with engine safety systems against overheating. Eccentric clamps are used to fix the wood blank.

It is worth noting that cutting machines belong to the type of equipment that can have a very extensive configuration, therefore, the versatility of such equipment is higher than that of other similar units.

At the same time, pay attention to the maximum dimensions of the workpiece for working on the machine, since this indicator is one of the most important in terms of the performance of the selected model.

Other types

In addition to the above types of machines, other types of machines are used in the production of furniture, which perform important functions. This equipment includes edgebanding models. As the name suggests, the main purpose of their work is to adhere a wide variety of edges to furniture panels. The primary classification is the division of units into straight and curved. The former, by virtue of their functionality, can glue edges only on straight surfaces, while the latter do it along curved paths. At the moment, most modern machine tools have a universal application, and therefore work in both directions at once, which significantly saves working time and equipment costs.

Edge cladding is one part of the workflow and therefore has its own time and place. The stage of such processing, as a rule, follows immediately after the manufacture of blanks on sawing and cutting equipment. The sheet material for the panels is fed to a cladding machine, which glues an edge with a thickness of 0.3 to 5 mm. At the same time, it is highly desirable that the equipment be equipped with an automatic workpiece feeding system, due to which operation is simplified and the time required to ensure the production process is reduced. The working speed of this function reaches 5-8 m / min.

Initially, the machine applies glue of a certain temperature to the surface of the workpiece, while the edge is in contact with the part and at the same time is cut in height. During the movement of the material, the part to be glued is pressed against it, thereby ensuring an effective work result. At the very end, finishing takes place, that is, excess glue is removed, and residual irregularities and roughness are polished.

Most often, edgebanding machines are necessary if the furniture is made of chipboard. As for the variations of the models, they are presented in a variety of forms and correspond to the areas of application in which the production of furniture is supposed.

Another type of machine can be called thicknessing machines. Their function is very important, since it consists in the final preparation of the part from the solid. The main gash occurs in thickness, which distinguishes these machines from others. The most basic classification of planers is the division into one-sided and double-sided. In the first case, there is only one knife shaft and is located at the bottom. This option is noticeably cheaper, but with a high complexity of work, you will have to run the same workpiece at least twice. In a continuous production environment, this can cause temporary delays if the furniture itself needs additional processing.

The two-sided execution mode is good because the design has two knife shafts, which are located at the top and bottom. The run of the workpiece in this case will be the finest. An equally important element in thicknesser machines is the working table. It should be quite large so that workpieces of different sizes can be placed on it. The main knot adjustments are in the planing depth and width. Expensive professional products can be equipped with CNC systems that bring all indicators to the highest accuracy. In this case, the user controls the equipment through the dashboard without directly participating in the process.

An obligatory element of the planer is the presence of a protection system in the form of a thermal relay. It simply shuts off the engine in critical situations when an excessively large load is placed on it. This situation occurs for many reasons, but the most common of them are drops in the power grid system and too long continuous operation of equipment.

Additional pieces of equipment include vacuum presses for forming MDF facades. They apply a layer of material in such a way that there is no oxygen left under it, and the finished film holds for a very long time and reliably. Structurally, this technique consists of a vacuum table, a pump for pumping out air, a clamping frame made of durable metal, as well as a heating unit and a cover.

It is these types of machines that are among the most essential in the production of furniture of various sizes. Of course, there are other types of equipment that have narrower or wider functionality. Most of them have combined functions and are capable of performing both basic and minor operations.

But the availability of these machines depends on the type of product being manufactured, while the models presented earlier are most often used in enterprises and factories with a very different volume of products.

Selection Tips

Among the large number of equipment, it is difficult to find something specific. Therefore, first of all, you need to decide what kind of final product you are going to produce. After that, you need to make a list of operations, the implementation of which will lead to the creation of good quality furniture. Once you have a certain understanding of the different work processes, you can begin to select machines according to their field of application. It is important to understand that some units duplicate each other in terms of functionality, so you can make a choice in favor of both universal equipment and highly specialized equipment.

In this situation, an equally important selection criterion is a set of technical characteristics. They are worth studying in conjunction with the basic and optional machine designs. The more varied the possibilities for modifying the product, the better for the consumer, because in the future it will be possible to improve the unit in order to develop production. It is very important to pay attention not only to the various technologies and functions of equipment, but also to the quality of the materials of manufacture. This is especially true for machines where there is a bed. It is the basis and must be very reliable and durable, since all the equipment units are located on it.

Before choosing a model, do not forget to study the reviews and opinions of other buyers, because some of the shortcomings of the technique can be identified only after some time of use.

The comment was sent successfully.