Overview of jig boring machines and their operation

During the production of various products, it is very important to observe accuracy and accuracy. For this, there are machines that allow you to do what a person cannot. When creating blanks, special attention should be paid to the most diverse aspects and elements of the product. For this, jig boring machines are used, represented by many models in the current equipment market.

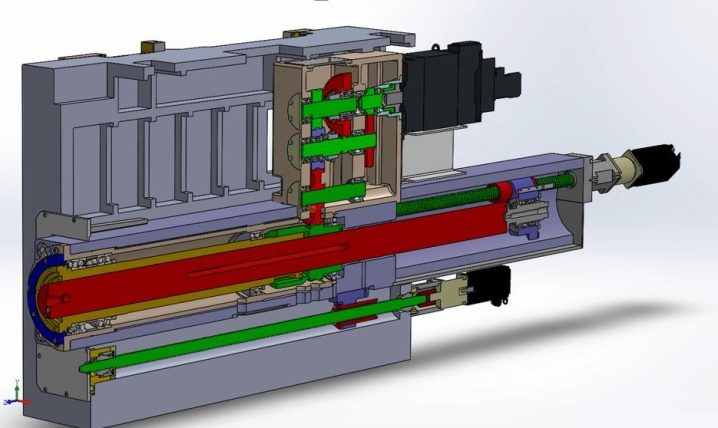

Device and principle of operation

The basic principle of operation of this type of technique is to process holes in the most precise execution. For this, a coordinate system is used, which allows the most varied processing of the workpiece in accordance with the production goals. The main working mechanism is the spindle, which has a horizontal or vertical position. A device that holds the working tool is attached to it.

A feature of jig boring machines is the versatility in the selection of the cutting device. It can be a drill of various shapes and diameters, cutters, taps, countersinks and other similar tools. Moreover, their maximum dimensions depend on the specific model of the machine and its classification. A spindle with a fixed attachment moves in a linear direction along a given axis.

Separately, it is worth paying attention to the device of such a machine. Its basis, like other types of equipment, is the bed. It is she who accounts for the entire physical load after assembling the equipment, so this part of the structure must necessarily be made of very hard materials. Often it becomes cast iron. The next part of the machine is the working table, on which the workpiece is placed and fixed, thereby preparing it for processing.

This structural element is equipped with a slide, so that it can be moved in accordance with the coordinate system and adjusted to the cutting tool with the required side.

Above is the boring head of the spindle, which works to make the required hole. The machine is driven by a motor of a certain power and the number of spindle revolutions per minute.

Appointment

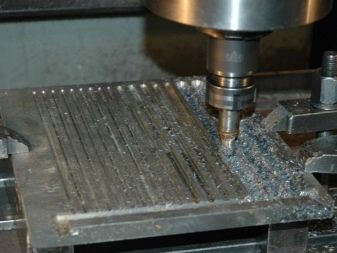

Jig boring machines can be classified as universal equipment, since they can perform a wide range of operations within their scope of application. The most basic among them are drilling and boring holes, both in the rough and in the final version. This is possible due to the ease of changing the cutting tool, which can be of different sizes. Also, such units are often used for turning cylindrical surfaces, machining the ends of holes, their countersinking and deployment.

The functions of jig boring machines include surface milling and thread formation. In general, the equipment is quite useful and is intended both for use in mass production and for the manufacture of unique blanks per piece. This type of equipment can process both metal structures and a variety of types of wood, and therefore is used in many areas: the manufacture of parts, furniture, large-sized equipment, factory production and other industries.

The design features of jig boring models allow you to create holes in the most difficult parts, for example, when you need to work at an angle or in perpendicular planes. Also, due to optical devices, it is possible to perform very accurate measurements in parts and calculate the distance between the centers of the workpieces. Adjustment up to 0.001mm provides reliable information.

The coordinate system enables the machine to perform operations in a variety of ways.

Species overview

By design

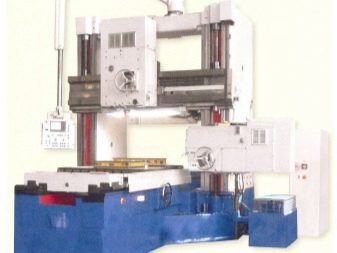

Depending on the layout, the machines are divided into single-column and double-column. In the first case, we are talking about those models that themselves have average dimensions and, accordingly, a frame. Such products are equipped with a cross table, on which the workpiece moves in the horizontal plane along the perpendicular. Structurally, single-column models are simpler, but their price is lower. These units are mostly used in medium-sized enterprises and are equipped with basic technological functions.

Their number and versatility make it possible to carry out a considerable working volume, but nevertheless they are inferior to two-column machines, which, in turn, are distinguished by the presence of a second column.

It performs several functions at once. The first of them is to increase the strength and rigidity of the structure, since the two-post models are wider, their tables are large in size. The second goal is the placement of additional technological systems and assemblies so that the work is more varied and more accurate, in contrast to the single-column one. A feature of the operation of such models is that the table moves on a slide between the racks, and the spindle moves vertically.

By level of automation

The initial set of automation functions for jig boring machines implies the ability to specify the indication during the set of the coordinate system. This technology makes it easier to adjust the technique and allows you to better navigate during various operations. Other features are automatic tool change and easy access to workpiece changes. Very useful options, with the help of which the user will spend less time preparing the machine for the next stages of processing or rearranging the parts on the table.

Usually, these possibilities are used in cases where production does not consist in constant work on the same blanks, but in the creation of small-batch products. It is for this reason that the tools used change periodically, and the desktop adapts to new workpieces. The most advanced machines are equipped with a CNC system, which makes the operation of the product the most automated and easy to use.

The meaning of CNC is that with the help of certain software you can set all the necessary parameters for processing, thereby achieving its accuracy and step-by-step execution on the machine.

Also, most of the applications used for this support a considerable number of solutions for both tools and visual creation of blanks with the ability to preview work on them. Using these manipulations, you can create algorithms for roughing and finishing with different spindle strokes, set the number of its revolutions, change direction vectors, and much more.

The CNC takes the operation of the equipment to a new level, because the user only needs to configure the program, having previously checked it in the editor, and it is not necessary to use the machine. After starting the unit, it remains only to monitor the working process and the correctness of its implementation. There are also additional options for the CNC, for example, the connection of various automated parts of the structure.

Rigging

The main accessories of the machine are cutters, which are attached to the structure due to the shank head. The holder has a free play so that the cutting tool can do the job in different ways. Among other types of equipment for jig boring machines, individual structures can be distinguished, one of which is a rotary table. It makes it possible to unfold the part in such a way as not to change the already set program.

The number and variability of tooling parts depend on the configuration, which, in turn, is presented by each manufacturer individually. Therefore, before buying a machine, you need to study not only the basic set of the product, but also the possibilities for its modernization in the future, if the scope of application changes or the existing characteristics of the equipment are not enough.

Top manufacturers

- JSC "Stan-Samara" is a domestic manufacturer that specializes in jig boring machines. The company focuses on a variety of assortments, and therefore subdivides its products into particularly precise and high-precision ones. The units are equipped with digital systems, due to which the operating efficiency reaches good indicators. The firm's models are often used at large enterprises in Russia and the CIS countries. Also JSC "Stan-Samara" sells separate parts of the structure, which gives the buyer the opportunity to purchase additional parts in case of their breakdown. The machines differ in their technical characteristics, configuration, dimensions and price.

- MZKRS is another Russian manufacturer, known since Soviet times. The Moscow enterprise gained popularity due to the reliability and versatility of its equipment. Among them there are units with DRO and CNC. The technique is distinguished by ease of operation and serial production of models, which allows you to choose between standard and modified types of machines. At the moment, the enterprise has ceased to exist, but some models can be found on sale.

- TOS Varnsdorf is a well-known Czech brand, under which various production machines are manufactured. The most popular jig boring model is the WHN (Q) 13/15 CNC, which can handle workpieces weighing up to 25 tons. The control is carried out by a special system with which you can set parameters and use integrated technologies. These include metrology function, simplified head calibration, modular headstock interface, software remote diagnostics, and more.

The manufacturer uses a number of options, thanks to which you can personalize the machine for the needs of production.

Operating tips

The operation of jig boring machines, like any similar equipment, must be carried out in accordance with the rules. After purchasing the machine and assembling it, it is necessary to check the operating condition of the unit. Carefully inspect all components and parts of the structure so that they are not damaged. This is especially true of the engine, network system and other elements, in case of problems in which the machine cannot be used.

Also, periodically perform maintenance on the software and the CNC, if present. During work, when securing the workpiece, cutting tools and other parts, check that the fasteners are secure. Do not forget to periodically replace the nozzles, because they tend to grind off.

Take full care of the safety of the site where the unit is located. The workplace must be clean and prepared for use.

Do not forget that the machine has a certain configuration, therefore unauthorized design changes are strictly prohibited. If the product becomes faulty, then the first step should be to study the instructions and other documentation, which may contain information about the basic service and a description of the causes of the breakdown with their possible remedies. If the malfunction is too serious, then professional workers should repair the equipment. Remember that all adjustments must be made in accordance with the rules of operation.

The comment was sent successfully.