All about Fokin's flat cutters

The Fokin flat cutter is a useful tool that is designed for processing plants in greenhouses and garden plots. The unit was patented in Russia and was recognized all over the world, having received many prizes and medals at international exhibitions. This tool greatly reduces the effort required to cultivate a summer cottage or garden plot.

For farmers and summer residents, such a tool has become an effective help.

Description

Fokin's flat cutter is a device that makes it possible to work the land manually, while applying a minimum amount of effort. The authorship and patent for this invention belongs to V.V. Fokin, a talented innovator who invented an original tool that facilitates the hard work of a working agrarian.

The flat cutter has a positive effect on the condition of the soil and has several important functions:

- shovel;

- rake;

- hoe.

Flat cutters are of three types:

- combined tool;

- large flat cutter;

- small manual flat cutter.

In total, this tool can do about 20 types of different work.

The unit is very effective when treating a site from weeds; it cuts off the root system of harmful plants deep in the soil (up to 6 cm).

The soil is cultivated without significant damage, while the weeds die. Also, noticeably less effort is spent during the production process, productivity is significantly increased.

Advantages and disadvantages.

The indisputable advantages of the unit are as follows.

- The soil is cultivated in a gentle manner and is subjected to delicate intervention. All beneficial microorganisms and insects remain in their habitat.

- No need to spend unnecessary physical effort to process the site.

- Annual and perennial weeds are effectively eliminated, while their root system is damaged and becomes an additional "feed" for the development of useful crops.

Moldless soil cultivation, which is carried out by a flat cutter, gives the following advantages:

- optimal conditions for plant development are preserved;

- the soil is saturated with oxygen;

- the employee spends a minimum of physical effort.

Of the disadvantages of the plane cutter, it can be pointed out that the unit cannot process areas where there is dense growth of weeds. If the area is too large, then the plane cutter may not cope with the volume.

A plane cutter should not be confused with a hoe - these are different tools, they also function in different ways.

Views

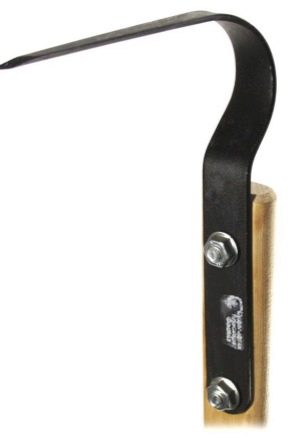

The unit itself has the configuration of a bent plate, the edges of which are well sharpened on a grinding machine. The performance of this device depends on the quality and strength of the metal. Most often, the manufacturer offers sets of two tools (large format and tools of small parameters).

With a large flat cutter, it is handy to handle large beds, weed weeds, and use it for mowing tall grass. The small plane cutter is ideal for weeding and thinning plants, agar work in greenhouses.

It is very good to huddle ready-made plants with such a device, while usually wide blades are involved. Correct hilling requires that the wide blade is immersed in the soil for a minimum distance, then with the help of small oscillatory movements the soil is "fluffed".

It is also good to level the ground with a flat cutter and fill in the seeds.This is done using a wide blade as well.

There is an additional hole in the plane cutter, which makes it possible to change the angle of the cutting knives, you can also modify the functionality of the device for right and left-handed use.

It is important not to increase the overheating of the tool during sharpening so that the “blunt” edge does not lose its performance characteristics and strength characteristics.

Having bought a tool, you should test it for some time, understand the principles of its operation. You should also adjust the functionality so that it optimally matches the parameters of the owner.

There are 6 types of flat cutters in total.

- Large size "cloth", it is designed to work in large areas.

- Small size "cloth"... Designed for processing plots of no more than 6 acres. Ideal for soft soil cultivation where large energy resources are not required.

- "The Mighty Man" makes it possible to quickly and efficiently process various young plants, it has an increased cutting edge.

- "Krepysh"... This tool can be used on clay soils, it has a short blade, while the width remains standard.

- Small flat cutter Is a machine that works effectively in the space between the beds.

- Hoe - plane cutter for working with "heavy" clay soils, the blade of this tool is very wide.

The large flat cutter is convenient for working the soil (furrows) during sowing. Also, this device is often used for weeding and loosening.

It is important to note that a separate handle has been designed for flat cutters, which has a flat section, its edges are rounded. This configuration allows you to work more productively, while reducing the risk of corns.

Models

To properly use the full potential of a flat cutter, a certain amount of practice and experience is required. The models "Strizh" and "Sudogodsky" are especially popular among summer residents, the reviews about them are the most positive. Flat cutter "Strizh" is well suited for processing loamy soil... It does an excellent job of loosening as well as removing weeds. A plane cutter is made of a handle and two combined blades (they resemble hearts).

There are three types of this flat cutter:

- enlarged sizes;

- average;

- miniature shape (handle only 66 cm).

"Swift" can handle soil to a depth of 16 cm... It is best to start working in the second half of March, when the snow melts, the soil dries up a little. Preventive treatment with this flat cutter lasts throughout the season (depth up to 6 cm). It is convenient to work with a small flat cutter in greenhouses. The cutting section provides the ability to effectively remove weeds with a branched root system.

Well, this tool is suitable for working with such plants:

- flowers;

- garlic;

- onion.

The model of this flat cutter is designed to work in:

- greenhouses;

- greenhouses;

- greenhouses.

One edge of the blade is straight (works the soil up to 4 cm deep), the second edge has the shape of a wedge, the working depth is up to 8 cm. The "Strizh" is especially well suited for hilling small plants, especially potatoes. Also the plane cutter is suitable for cutting weeds and grass.

This tool is more effective than a simple braid.

How to choose?

On trading floors, you can often find counterfeit flat cutters. They are distinguished from real units by their extremely low price. Buying a low-quality flat cutter means throwing money down the drain, such a tool will work for a matter of days (if not hours).

There is a guarantee for these flat cutters, quality certificates are attached, the service life of such a tool is at least 3 years.

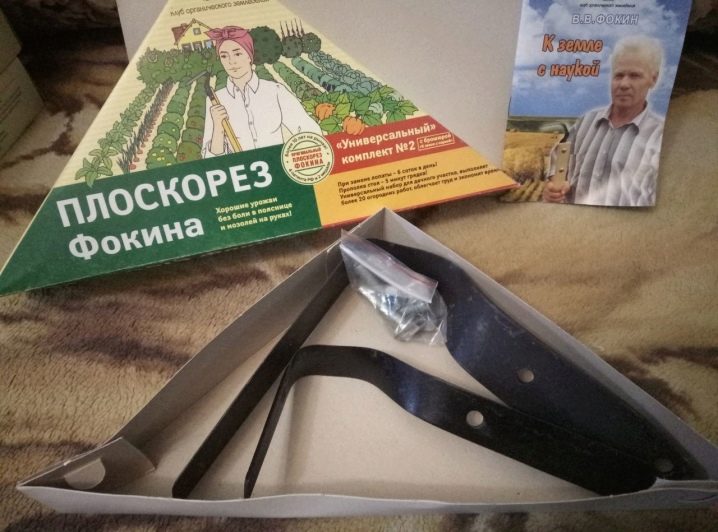

A real "native" unit looks like this:

- the box bears the logo: "Organic products club";

- the set contains a company manual with a portrait of the author;

- there are also fasteners with a special coating;

- all flat cutters are produced in large and miniature formats, and they are identical in configuration;

- all tools sold by this manufacturer are coated with reliable anticorrosive, and if the unit is counterfeit, then it is painted with enamel, which can be easily scraped off even with a fingernail.

The following signs give out a fake:

- poor quality metal;

- the weight of the unit is small;

- the box is made of substandard material;

- cloudy printing on labels;

- the instruction (if any) looks wrinkled, the text font is blurry;

- bad fasteners that will break after a short time.

How to work?

It is not difficult to use a flat cutter correctly. The tool blade moves in a parallel plane. If the blade deflects at any angle, then the tilt of the handle changes. Thus, the blade angle can be easily and efficiently adjusted. It is possible to understand how the unit works only in test mode, there is nothing complicated about it, but you need to “feel” the behavior of the mechanism.

The blade is installed in the ground to a depth of no more than 95 cm, the tool must be located close to the working farmer.

It is recommended to do weeding when the weeds or grass have not yet grown very much, in which case less effort will have to be spent on eliminating them.

Operations can be of this type (instructions for use).

- Straightening the beds. The unit moves along the surface of the ground, without any effort.

- Loosening of the soil. In this case, the soil is loosened to a distance that corresponds to the parameters of the canvas itself.

- You can do the processing of virgin lands.

- It is possible to process "heavy" soils from clay and loam.

- Make furrows to install seeds in the ground. In this case, the tool is immersed in the soil and a seed furrow is made. To plant seedlings, they usually use a large format. A small tool can be used to plant seeds.

- If you hit the "heel" of the plane cutter on the stuck together clods of soil, then they are easy to crumble. The same manipulations can be done with weeds. The curved part of the unit makes it possible to remove a rather thick stem of any plant located in the garden.

- The root system can be damaged in weeds if the blade of the implement is brought close to the plant during operation.

- With a flat cutter, you can huddle and thin out plants, thin out young crops (carrots, pumpkin, dill).

- You can remove the soil cover that appears next to the tree trunk, clear manure from the barns, slit the aisles, collect hay, evenly distribute fertilizer over the treated soil.

It is important to understand that you should not work with a flat cutter like a hoe or a shovel. It is worth holding the plane cutter a little differently, you cannot knock it on the ground, during work you should occupy a perpendicular position relative to the ground, do not bend to the right or left.

Before starting work, you should adjust the unit to the parameters of your body. If you do not follow these guidelines, the device may jam during operation when the blade is immersed in the soil.

If the tool works without difficulty, all parameters will then be set correctly. Before starting work, you should familiarize yourself with the detailed instructions that are attached to the product. It is recommended to maintain correct posture during work. The muscles of the back should be relaxed, the trunk can bend forward slightly. There should be no more than 20 centimeters of distance between the hands, the thumbs slightly rise up during work.

It is also important to adjust the machine to suit the worker's specifications. The handle of the tool should be a couple of tens of centimeters below shoulder level, it is important to choose the right parameters of the handle. If after 2-3 hours of work the body feels tired and aching, then this indicates that the work with the plane cutter was done incorrectly.

How to do it yourself?

It is not difficult to make a flat cutter yourself. One end of the cutting is made rounded, in the lower part it is necessary to leave only a couple of tens of centimeters without any rounding, thereby the process of forming a hole in which the device will be mounted will be ensured. The shank must be processed without fail with sandpaper and a file, there should not be any roughness or burrs.

Also, the tree is treated with a special anticorrosive and covered with linseed oil and varnish. This will ensure the service life of the unit over time.

All bolted connections should be provided with counter washers, this will make it possible to use the device more efficiently and productively. The counter washers will securely fix the joint assembly. It is not difficult to make a plane cutter with your own hands, it is enough to find the desired drawing and collect all the necessary materials. First of all, a strip of metal is required, the dimensions are as follows (thickness up to 5 mm, length up to 45 cm).

The metal heats up, at least four folds are made:

- the first bend is made at an angle of 96-104 degrees;

- the second bend is 109-132 degrees;

- the third bend is the same in terms of parameters as the first;

- the fourth is adjustable.

The angles should be 32-42 degrees. Then the metal should be allowed to cool. The edge of the blade should be sharpened on a special machine. To attach the handle, 3-4 holes must be drilled. The shape of the handle will be different from the shape of the handle for a shovel, its shape is rectangular, which excludes the possibility of sliding in the hands.

To more accurately determine the dimensions, it is recommended to look at the drawings by downloading them on the Internet. Agrarians make a plane cutter blade from a braid, cutting it off by 20 centimeters.

With this work, you should have a grinder on hand. Sharpen the blade at an angle of at least 40 degrees. The flat cutter can become more efficient in soil cultivation if you put it on a walk-behind tractor. Labor productivity increases several times. It is advisable to select steel for the blade of a flat cutter of 67G grade, for this a spring from a VAZ or a torsion bar suspension from "Zaporozhets" is suitable.

The sharpening of the plane cutter is done on the appropriate machine, processing should begin from the very edge of the blade. It is also recommended to do the hardening of the metal.

A similar operation is done as follows:

- technical oil is poured into the container;

- the part is processed with a blowtorch until “redness” appears, then it is sharply immersed in oil;

- it is recommended to repeat this operation 2-3 times.

The following wood is suitable for the cutting:

- Pine;

- Birch;

- ash.

The handle should be carefully processed with sandpaper and anticorrosive, and also varnished. Of the tools for creating a do-it-yourself flat cutter, you will need:

- turbine;

- hammer;

- blowtorch;

- pliers;

- vice;

- butter;

- bolts, nuts.

Care

During the period of work on weeding the beds, it is imperative to place the blade of the plane cutter flat. In this case, it is recommended to turn it slightly to the left. It is necessary to "drag" the unit behind you a little, while slightly pressing the handle.

When cutting weeds, the device rises slightly when:

- the beds are arranged;

- the soil is leveled;

- seeds are poured.

The tool then acts as a rake, with the blade turning to the right and lying on the surface. If the soil is loosened, as well as the removal of weed rhizomes, the blade in this case can be placed at any angle of inclination. The blades must be properly sharpened before each start of work. The sharper the blade, the easier it will be to work with such a unit.

The tool is especially effective when processing:

- raspberry;

- strawberries and strawberries;

- the layout of the beds;

- hilling plants.

Before you start sharpening the blade, you should carefully inspect it for damage and chips.When sharpening the tool, it is recommended not to forget to sharpen first of all the edge of the blade, which is located on the back side, you do not need to sharpen the front part, it may become even more dull.

It is strictly not recommended to overheat the edge of the blade during operation, the metal loses its performance characteristics. The blade edge is processed only at an angle of 45 degrees. When sharpening, you should actively use a hand file and a sharpening stone, as well as a circle.

How to work correctly with Fokin's flat cutter, see the next video.

The comment was sent successfully.