The subtleties of choosing insulation for the ceiling

Heat loss is an urgent problem in the Russian climate and cold winters. The cost of heating and energy resources is increasing every year. To reduce heating costs, heat insulation of residential heated premises is used. It is not enough to insulate the outer walls and floor, install modern double-glazed windows. Up to half of the heat can go through the roof to the street, since warm air is concentrated under the ceiling. Insulation will reduce these losses and create more comfortable living conditions.

Peculiarities

Thermal insulation of the ceiling will save heating costs in a private house. This will help apartment residents to increase the room temperature during the heating season. An additional insulating layer will get rid of mold and mildew on the ceiling.

When building your own home, you need to remember the importance of keeping warm. and initially lay the height of the ceiling, taking into account the parameters of the insulation. Depending on the use of the attic space, a method is chosen. When the attic does not imply an intense load, then thermal insulation of the attic floor itself is used. If the roof is used as an attic, then it is advisable to insulate the ceiling from the inside.

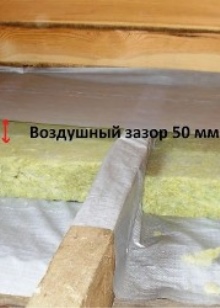

For installation on top of the ceiling, a vapor barrier must first be laid to protect the structure from moisture. As a vapor barrier, polyethylene or anti-condensation films, glassine and modern membranes are suitable. If bulk insulation is used, then the vapor barrier will also have a protective function, preventing its particles from entering through the seams of the plates or boards into the interior.

Apartment owners living on the top floors should also think about insulating the ceiling on their own from the inside. In a nine-story panel building, taking into account the deterioration of the housing stock, it becomes necessary to protect the outer walls and ceiling. For this, you can use different types of materials. The main goal of correct installation is to create a monolithic layer of insulation in order to exclude warm air leaks.

Types of materials

For thermal insulation, materials are used that have low thermal conductivity. They are distinguished by the method of installation and manufacturing option.

There are the following types:

- roll;

- bulk;

- slab;

- foamy.

Roll

Mineral wool is produced in the form of rolls or mats of different sizes. Fibers differ depending on the material from which they are made.

The raw materials are:

- for stone - alloys of rocks;

- slag - waste of metallurgy;

- glass wool - sand, glass and dolomite.

For insulation of ceilings, they are often used:

- glass wool is the leader in thermal insulation, but it has difficulties in installation;

- basalt wool is preferable for self-laying.

Mineral wool is hygroscopic and high humidity leads to its destruction and an increase in thermal conductivity. This non-combustible material is versatile, suitable for wooden and concrete floors. High-quality insulation can be achieved when installed under the ceiling and in the attic, by changing the thickness of the layer. Light weight and low thermal conductivity allows for insulating attic floors with a layer of up to 200 mm.

Foamed polyethylene foam with a thickness of 2-25 mm is also sold in rolls. Isolone canvases of small thickness are used as a substrate for floor coverings.Foamed polyethylene is suitable for thermal insulation of walls and ceilings - from 0.5 cm with a foil layer on one side that reflects heat. Small thickness and lightness make it easy to mount Izolon on the inner surface of the ceiling and carry out further repairs with it. The material is durable, fireproof and exhibits high thermal and waterproofing properties.

Bulk

Bulk materials include:

- straw;

- sawdust;

- slag;

- Earth;

- expanded clay;

- foam glass;

- vermiculite;

- ecowool.

Warming with sawdust, straw and slag is considered a traditional method and has been used since ancient times. With the development of industry and the production of modern insulating heaters, the popularity of natural materials has declined.

The earth as insulation can be used as a temporary measure in the attic of a bathhouse. The loose layer should be more than 20 cm. The best option would be straw mixed with wet clay 10 cm thick. You can simply spread straw 30-50 cm thick. Slag is a secondary raw material from metal processing, which is used in construction as a cheap backfill insulation.

The availability and low cost of sawdust is a defining parameter for their use. The disadvantages of sawdust are obvious - they absorb water well, are highly flammable, and can serve as a home for rodents and insects. Over time, its insulating properties deteriorate, it is necessary to lay an additional layer. To reduce the negative effects of using wood insulation, dry sawdust is mixed with lime or cement.

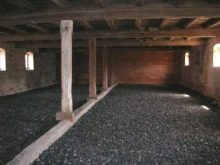

Expanded clay is a porous free-flowing building material based on clay in the form of granules of various sizes. The backfilled layer depends on the external weather conditions of the region and can reach up to 50 cm. Expanded clay is distinguished by fire resistance and frost resistance. Its low price and durability make it a popular environmentally friendly heat insulator.

It possesses lower heat-conducting properties, in comparison with expanded clay, foam glass... This granular foamed mass can be produced in blocks for wall insulation. The positive characteristics of the material are: durability, strength, frost resistance, moisture resistance, environmental friendliness. Synthetics do not attract rodents and do not serve as a favorable breeding ground for bacteria. But foam glass was not widely used due to its high cost.

Vermiculite - natural mica material, which becomes swollen at high temperature values, while acquiring a different shape. It has a low coefficient of thermal conductivity, fire resistance, durable and lightweight, which makes the material an excellent heat insulator. It possesses adsorbent properties, absorbs and releases water without deterioration in performance. The only drawback is its high cost.

Ecowool- modern natural cellulose insulation. The substances included in its composition prevent burning and decay. The level of thermal insulation is similar to that of mineral wool, but high vapor permeability does not lead to a decrease in heat capacity.

Ecowool can be laid in two ways. Self-dry ecowool is scattered over the entire area of the attic. Another method involves gluing using a special dampening and blowing machine, with which the material is applied to the battens. The second method is more professional and increases the thermal properties of ecowool by a third.

Tiled

It is easy to work with the tile material and you can make your own installation. Styrofoam is often used for styling, since it is affordable, moisture-resistant, frost-resistant, lightweight and inexpensive. The disadvantage of foam insulation is weak strength characteristics, in addition, it emits chemical compounds hazardous to health during combustion. Low vapor permeability imposes restrictions on its use with wooden structures.

Plates of extruded polystyrene foam are more durable in structure. It is also called penoplex. Due to their density, they have a lower thermal conductivity with a smaller thickness compared to foam. Penoplex does not form cold bridges, since it has grooves and is not required to seal the seams.

It is not recommended to insulate wooden houses with artificial materials, since wood needs ventilation. If you create a vapor barrier of foam or foam on the ceiling, then the steam coming from the living space will spoil the floors, contributing to the growth of fungus and mold.

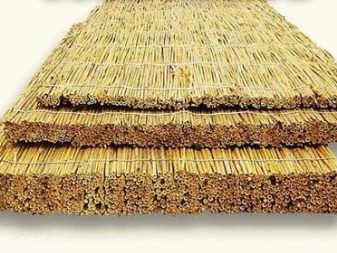

The traditional raw material for the insulation of wooden buildings is reeds. They are pressed in the form of mats, pre-treated with fire retardants. This inexpensive material allows well-ventilated attic space and does not need vapor barrier.

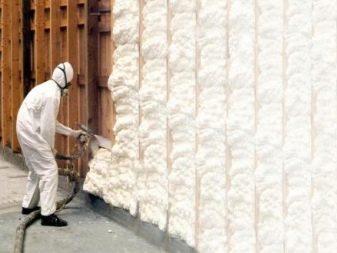

Foam

These materials include modern insulation with polyurethane foam and foam insulation. According to its characteristics, polyurethane is similar to foam, only it is applied in a liquid state, creating a durable airtight coating with high thermal insulation properties. Penoizol is an analogue of foam plastic in liquid form. The additives in its composition improve the quality of the material, making it fireproof.

Insulation is sprayed with a professional compressor of the required thickness. This work cannot be done independently, since special expensive equipment is required. To install thermal insulation, a company specializing in the production and installation of these heaters is invited.

Criterias of choice

When selecting thermal insulation for the ceiling, take into account the characteristics of the protective material, installation features, floor material, and the amount of material investments.

The following criteria for thermal insulation products will help you choose a heater:

- flammability;

- weight and size;

- durability;

- thermal conductivity;

- environmental friendliness;

- vapor permeability.

The main claim for various types of thermal insulation is their flammability. Sawdust, straw and styrofoam are highly flammable. Not exposed to fire vermiculite, expanded clay, foam glass, earth. Other types of heaters do not form a flame, but at high temperatures they melt. Fire safety requirements must always be observed, especially when stacking combustible materials.

The parameter of weight and size is important during the installation and transportation of building material. Weight is taken into account if one or two people are engaged in the work on the flooring of the insulation. Thickness is important when carrying out interior work.

The durability of thermal insulation depends on the strength of the starting material, operating conditions and the correctness of the laying of layers during installation. High-quality thermal protection should not change its properties during temperature changes and mechanical stress.

Thermal conductivity is the main indicator of a material, which characterizes the rate of heat transfer to the environment. The lowest coefficient in this sense is possessed by: penoplex, polyurethane, izolon, glass wool. Expanded clay passes heat best of all.

All types of bulk insulation and reed mats are considered environmentally friendly.

The vapor permeability index of the material is important for wooden structures, since wood is susceptible to moisture and is prone to condensation. Mineral wool has the highest level of vapor permeability. Artificial heaters are water-repellent, moisture-resistant and poorly vapor-permeable.

There are two types of floors in the house - made of wood and concrete, based on the properties of these structures, and choose the type of insulation. For a wooden house, it is better to give preference to thermal protection from natural raw materials. Eco-friendly materials have good vapor permeability and allow the wooden floors to be ventilated. Synthetic types are also suitable for concrete.

For insulation of the attic roof space, you can choose any insulation - bulk, roll, foam or shield. Above the rooms, the thickness of the insulating layer should be less than for external work. Roll and tile materials are usually used under the ceiling.

Often the selection criterion is the budget, which is spent on repairs. Cheap insulation can be selected depending on the type of floors and the operating conditions of the room. The availability of a certain type of insulation also depends on the cost of all work. Transportation of bulky and heavy material, rental of professional equipment for applying penoizol are also included in the total costs.

Application area

It is necessary to insulate the ceiling in all heated rooms. During installation, different heat insulators are used depending on the operating conditions of the room or the entire building.

In a private house, it is imperative to insulate the ceiling if the roofing cake itself does not contain thermal protection. For a two-story house, floor insulation will help keep the ground floor warm. Thermal insulation is required on the ground floor and if there is a basement underneath. This will prevent drafts and heat leakage through the floor. In a spacious basement, thermal insulation is laid from the inside. In the absence of such an opportunity, the floor is insulated over the floor using any material.

It is worth thinking about the insulation of the veranda roof.if it is used in winter and has heating. There is usually no heating on the terrace and there is no need to save heat. When a bathhouse or sauna is located in the house or on the site, then the creation of a warm roof must be taken responsibly, because this is a place of increased fire hazard and humidity. For the sauna, a fire-resistant vapor-permeable material is selected.

If the country house is visited in winter, then the attic definitely needs heat protection. An uninsulated structure is difficult to heat and maintain a comfortable temperature in it.

Tips & Tricks

External insulation allows you to choose any type of suitable material, not limited to roll or panel type. The best option is considered to be laying outside the floors than protection from the ceiling. But in the apartment you don't have to choose. In this case, penoplex or basalt wool are perfect for thermal insulation.

High-quality insulation of the upper floors of the room is capable of retaining up to 20% of the outgoing heat through the roof. Following the recommendations of the manufacturer of thermal insulation materials will help to avoid annoying mistakes during installation and operation.

See below for the intricacies of choosing a heater.

The comment was sent successfully.