Plastic ceiling: pros and cons

A few years ago, plastic ceilings were perceived by many as exclusively "office interior" or "summer cottage". Today, plastic ceilings are found in interiors more and more often.

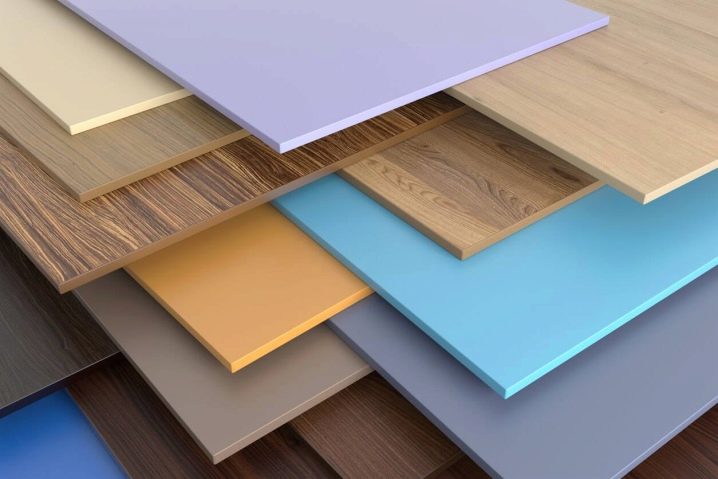

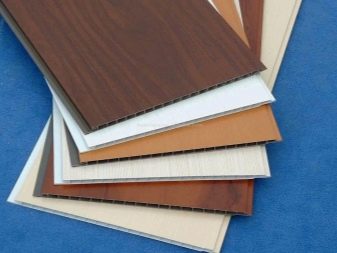

Plastic panels and lining, presented by modern manufacturers in building supermarkets, outwardly are practically indistinguishable from natural materials and do not have a characteristic "plastic sheen" and a specific smell.

Peculiarities

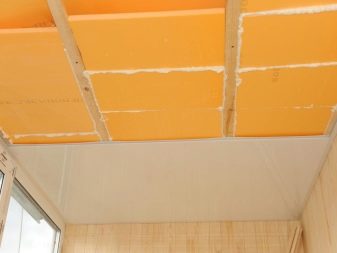

It is safe to say that a modern plastic ceiling will decorate the interior of both a city apartment and a country house. Before installing the plastic ceiling, it is necessary to clean the surface of dirt, eliminate cracks, and then process the base with special antiseptics, since a fungus may appear under the plastic surface.

Determine the places where the lighting fixtures will be installed, choose their type It is best to purchase them in advance. If you have chosen PVC panels for finishing, then the wiring must be installed in advance.

So, your ceiling can be made using PVC panels, plastic lining or plastic film (stretch plastic ceiling). At the same time, it is quite possible to undertake the installation of panels and lining with your own hands, but it is better to entrust the subtleties of working with a stretch ceiling to specialists.

Let's dwell in a little more detail on the main options for finishing ceilings with PVC materials.

PVC panel ceiling

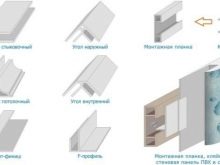

PVC panels are most often presented on the market in the form of plates or sheets. The plates are overwhelmingly square, with sides ranging from 30 to 100 centimeters. To fix the slabs around the entire perimeter of the room, you will have to install special mounting shelves.

PVC sheets come in different lengths (up to 4 meters) and different widths (up to 2 meters). The order of work is always approximately the same and consists of the following stages:

- Reinforce the corners that will hold the PVC panels with self-tapping screws.

- Cut the plastic panels if necessary, you can use a regular hacksaw.

- If there are burrs at the edges of the panels, sand them off with sandpaper.

- Make a layout for future lighting fixtures and cut holes for them.

- Start securing the panels by positioning them across the profile.

- It's okay if some of the panels are not perfectly aligned; alignment will help to give a neat look, which is recommended before installing the last panel, this is done by loosening or tightening the screws.

Ceiling made of plastic lining or "slatted ceiling"

This finish is the cheapest, while it is quite functional and diverse. Consider the main stages of installing a ceiling made of plastic lining:

- Before starting work, make the markings along which you will carry out the installation of the ceiling. First, you need to find the lowest point of the ceiling. From this point, retreat down about 10 centimeters. This will be the level of the new ceiling.

Using a water level, we markup in all corners of the ceiling space (there can be several marks if the ceiling is not rectangular, but has a broken shape). According to these markings, further installation of the frame will be carried out.

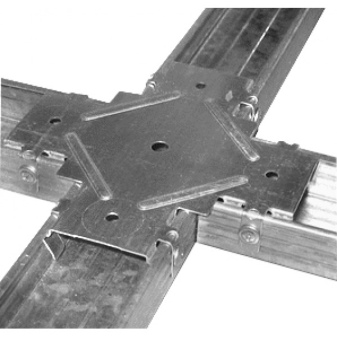

- The frame can be made of wood, but metal will be more reliable and stronger.For a metal frame, you will need self-tapping screws with a press washer and ordinary self-tapping screws, a construction stapler, nails, clips, rope, U-shaped fasteners and crabs, as well as metal CD-profile (for the frame base) and UD-profile (for the perimeter frame).

- Draw a line along the perimeter of the walls with a pencil and fix the UD profile along it using dowels; 2 control CD-profiles are fixed at different ends of the room, not too close to the wall (10-15 cm); using P-mounts, we mount a profile to the ceiling along a stretched fishing line or rope (step up to 50 cm).

- We fix the jumpers with crab fasteners.

- We prepare the wiring and communications, leaving the loops where the wires will be output.

- We install the lining on the frame.

Vinyl stretch ceiling (PVC film)

This is a smooth and neat canvas that is attached to a metal or plastic profile at various distances from the main ceiling.

PVC materials are quite tough, but immediately before installation, the canvas is heated with a special gas gun, thanks to which it becomes elastic. When the canvas cools down, it will stretch over the profile and the ceiling will become perfectly smooth.

Advantages and disadvantages

There are many advantages to plastic finishing material. Perhaps they are able to cover the few disadvantages available.

Let's talk about the main positive points:

- Plastic panels are much cheaper than any other materials used in ceiling decoration.

- Ceiling defects (irregularities, seams, cracks) will remain hidden under the finish. Also, if you need to hide pipes or wiring, plastic panels will do the job best.

- Installation of a plastic panel ceiling is available even for novice craftsmen and does not take much time.

- No special tools are needed for mounting plastic panels.

- If the ceiling needs to be cleaned, you can easily do it yourself.

- Finishing materials made of plastic for ceilings do not fade in the sun and are resistant to temperature extremes.

- A variety of textures and shades of plastic panels make it possible to match them to any interior.

- When using plastic lining, the load on the ceiling frame is very small.

- There is no need to be afraid of special smells - modern plastic panels practically do not smell, and a couple of days after unpacking, even the most sensitive nose will not feel an unwanted smell.

- This is a particularly moisture resistant material that will not change its appearance even after direct contact with water.

- Plastic panels are durable and will last you as long as you need it, and the harmfulness of plastic to human health is a clear exaggeration, because modern technologies make it possible to make these finishing materials absolutely safe.

- Plastic has good sound insulation properties.

- If it is difficult to carry out standard electrical wiring into the room, then the installation of point LEDs in plastic panels will not be difficult and will perfectly cope with the tasks of the main and additional lighting.

The plastic finish has its drawbacks, which we are obliged to tell you about:

- Plastic panels are resistant to fairly high temperatures (up to 400 degrees), but if a fire does occur, the material will emit gas that is harmful to human health. A similar process can begin with smoldering material.

- The attractive appearance of plastic trims can be compromised by accidental scratches or bumps on the trim. Unfortunately, the damage cannot be repaired, and part of the ceiling will have to be replaced.

- Despite promises from panel manufacturers that the sun's rays will not damage the finish, keep in mind that white panels or white parts on colored panels can turn yellow.

- The last disadvantage is associated, rather, with aesthetic perception than with objective characteristics. The fact is that many perceive the plastic ceiling as "artificial", "office".It is worth noting an important point - modern PVC ceilings can look anything, including successfully imitating wood or stone, so the rejection of plastic finishes for reasons of aesthetics is just a delusion.

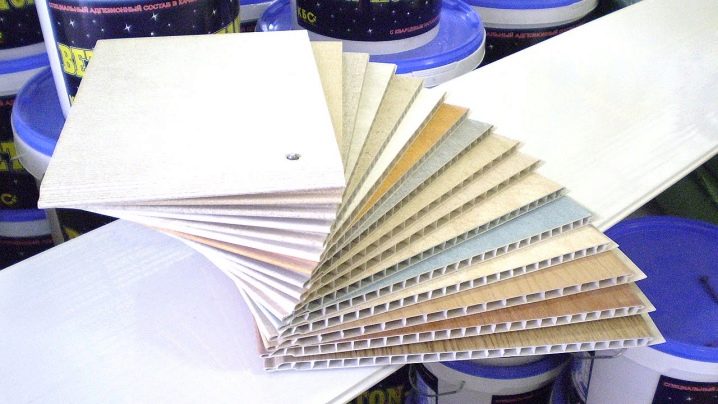

Sizes and shapes

Plastic ceiling trim is unusually diverse in size, shape, color and texture. The main groups are tiles, lining and sheet products, as well as stretch ceilings. Each of the groups differs not only in size, but also in rigidity, weight, and, of course, in price.

When choosing a finishing material, pay attention to the thickness of the plastic panels. For finishing the ceiling, you need to use a much thinner plastic than for walls (no more than 5 mm).

The size of individual elements of plastic trim (they are called "lamellas") depends on the group: narrow and long - lining, the largest - sheet products.

Plastic lining looks harmoniously in the decoration of ceilings in the country, on verandas, loggias and balconies, as well as in kitchens. Panels and sheet finishes are suitable for decorating living rooms and halls, and a stretch PVC ceiling will look good in any room.

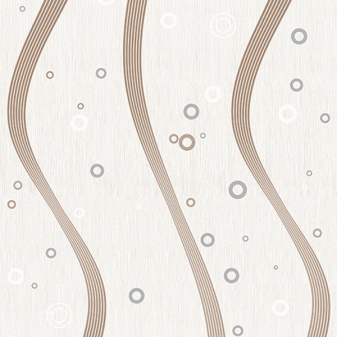

A special type of ceilings - curly... Such a ceiling is usually a combination of a PVC ceiling or plasterboard with tension structures. This is a complex ceiling, often multi-level with the use of complex shapes of various shapes and colors (rounded elements, spirals, waves, plants).

Volumetric stretch ceilings also fall into this group.

Despite the complex designs of curly ceilings and the complexity of the work, they have enough advantages. The main thing is attractiveness and originality. Also, the correct painting and the effective arrangement of the ceiling elements make the room look bigger and taller.

It also happens that the room needs to be made more comfortable and zone a large space. In these cases, curly ceilings are simply irreplaceable..

Under the curly ceilings, you can easily hide any communications or height differences - this is often necessary in a variety of rooms. When installing such structures, you need to take into account their large weight and remember that the ceiling must be very strong.

The most common curly ceilings:

- Ceiling with a rectangular "frame". A frame is suspended around the main suspended structure, into which spotlights are usually mounted. This design is also used in cases where you need to divide the ceiling into several rectangles (for example, if you like a traditional "Bavarian" ceiling with a white base and dark beams).

- Ceiling with multilevel ovals, circles and semicircles... Suitable for both the bedroom and the kitchen, since with the help of the uppermost level we can highlight any area in the room. A spectacular lamp is usually placed in the center of the circle.

- Wavy shapes can play the role of both a room divider into zones, and an effective decorative element for any part of the room.

- Flowers made of plasterboard or PVC materials, plants, leaves or any other complex patterns are suitable for giving the room an original, unique look. However, sometimes it is necessary to hide communications and irregularities of the main ceiling under complex structures.

Design

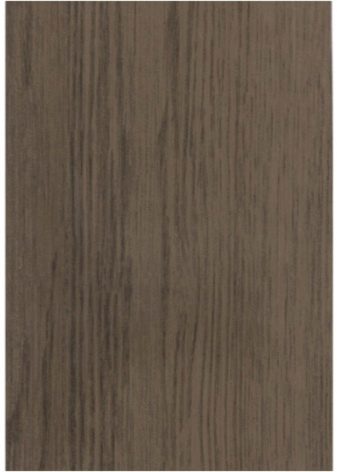

When choosing PVC materials for finishing the ceiling, consider the style of the interior of the room. Classic interiors require white ceilings, Mediterranean style goes well with "marble decor", cupids, roses and gold trim, and Provence allows the use of delicate azure blue, light olive, cream and other pastel shades. All woody shades and wood-like textures are suitable for the rustic style.

The more minimalistic the design, the stricter the ceiling finish should be. Cool shades of gray and beige go well with Scandinavian interior design.

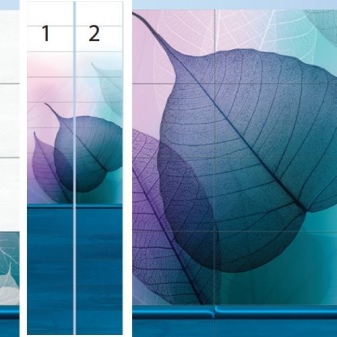

Remember that patterned PVC ceilings are only appropriate in children's rooms or in rooms of a certain style (for example, Mediterranean chic). If you doubt the appropriateness of a particular color of ceiling panels or PVC film, give preference to a white matte ceiling.

The decorativeness of the lamellas also depends on the type of their connection. It is easy to distinguish them even by their appearance - these are panels with a relief surface, products with bevelling and seamless panels.

Seamless panels are arranged so tightly to each other that seams are almost invisible... Panels with beveled or rusticated look like seamless lamellas, but in the end part, each element has a recess (rustic), which makes it easy to connect the panels into a single canvas.

For information on how to install a plastic ceiling with your own hands, see the next video.

Manufacturers

By choosing products from a reliable manufacturer, we can be sure of the quality of the goods. How to navigate the market, because there are many companies? We will introduce you to some of the companies that have proven themselves in the production of PVC finishing materials.

- Belgian Venta - a manufacturer with vast experience, constantly improving production technology and expanding the range. Even digital printing is used to apply a pattern to the surface of PVC.

- Forte Is an Italian company that has been producing finishing materials for over fifty years. Produces elegant panels in classic colors for ceilings and walls using modern equipment.

- Manufacturers of PVC materials from the Republic of Belarus have proven themselves from the best side. Excellent quality, European design and low prices of Belarusian PVC materials attract the attention of many buyers. The products of the company are presented in hardware stores and supermarkets Europrofile (own production of PVC panels and profiles), a major manufacturer and seller of various PVC materials Yu-plast, PVC West (has been working in the construction market for over 20 years).

- Krasnodar company "AnV-plast" has earned the respect of craftsmen and plastic panels sellers. The company uses domestic raw materials and domestic technologies. The quality of the products is quite high, and the price is much lower than that of foreign competitors.

- A popular domestic manufacturer from Magnitogorsk - Ural-Plast company. Its products are manufactured on foreign equipment, are distinguished by their spectacular design and a variety of colors.

Selection tips:

- Finishing materials are best purchased from specialized stores. Check the products for quality certificates, carefully study the composition of PVC materials. If you have any questions - contact consultants or sellers. Ask your consultant to immediately select all the necessary fasteners and other materials for you.

- Examine the PVC boards - they should not be cracked or otherwise damaged.

- Press lightly on the surface of the PVC sheet. No traces should remain on a quality product.

- Stiffening ribs should not be visible on the surface of the slab; when bent, the product should not crack.

- When choosing PVC panels, be guided by the layout and dimensions of the room. On a small loggia or in a narrow corridor, use PVC elements of the minimum length and width. Large squares will be appropriate in a large room or spacious hall.

Examples in the interior

A two-level figured ceiling, which allows you to visually enlarge the space of a small room, will become a real decoration of a modern interior.

PVC wood-like lining looks almost like a real one, and will serve you much longer. If necessary, such a ceiling can be easily cleaned, which is important for the kitchen.

A stretch ceiling made of PVC film with a holographic pattern will decorate the interior in a minimalist or hi-tech style.

Plastic panels in the bathroom are a spectacular and much cheaper replacement for tiled finishes. Using panels with the same pattern for walls and ceilings can visually enlarge a small bathroom.

A plastic ceiling made of PVC sheet on a loggia or balcony will give the room a neat and modern look. If you place point light sources on the ceiling of the loggia, then you can relax here even in the evening.

We spend a lot of time in the kitchen, so a beautiful and functional kitchen ceiling is a must for a modern apartment. In addition, he will perfectly cope with the division of space into a dining area and a cooking area.

A stretch ceiling in a bathroom can turn it into a completely futuristic and unusually spectacular room. Correctly positioned fixtures, chrome-plated metal finishes and mirrored details will create a multitude of sources of light and sparkle.

The comment was sent successfully.