How to insulate the ceiling in a private house from the inside?

In winter, the heat loss of the ceiling structure is about 15%. Since it is warm in the house and cold outside, condensation forms in the room, creating a favorable atmosphere for the growth of bacteria and fungi. Therefore, it is necessary to think about effective insulation of the ceiling in the interior of the house.

Peculiarities

The main feature of ceiling insulation from the inside is the impossibility of organizing a condenser drain. Drainage walls could remedy the situation. However, their cost is not affordable for everyone. Depending on the season, the ceiling can quickly heat up and cool down. For this reason, the main technology of ceiling insulation is focused on preventing condensation from forming in the finished structure.

To create a warm and cozy atmosphere in your home, it is recommended to use mineral wool in the form of a roll or slab.

Such insulation is popularly called glass wool. If this material is used in conjunction with a false ceiling, drywall will create an insurmountable barrier to the outgoing heat.

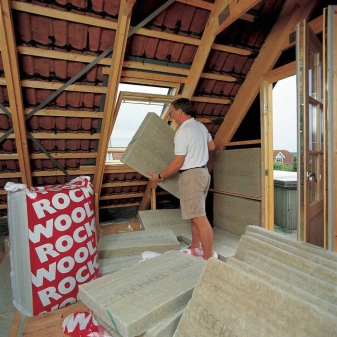

The installation of mineral wool should be divided into several stages:

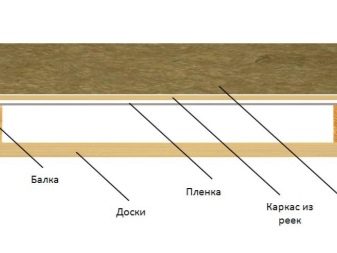

- Collection and installation of the frame on a metal or wooden base. For this process, it is worth using an electric drill and dowels.

- Filling the free space between the parts with mineral wool. A special tile adhesive is used as an attachment. It instantly solidifies and creates a reliable fastening of the material. Do not forget about the additional installation of a vapor barrier.

- At the final stage of work, drywall is installed on the ceiling. It is recommended to use hardened steel self-tapping screws as fasteners (they are highly durable and can withstand maximum loads).

It will seem to an ordinary person that the installation technology is quite simple. However, any installation process has its own nuances. It is strictly forbidden to press mineral wool. The main effect of heat conservation is that the bubbles located in the interior of the material do not provide heat transfer between the ceiling and the attic.

Spotlights can also pose a problem. Energy saving lamps are known to be very hot. The mounted insulation will prevent heat removal from the lamps, which will lead to their rapid breakdown. An alternative option is to create an additional gap between the luminaires and the insulation (preventing heat dissipation and air circulation).

Types and materials

Various shops and markets for building materials offer a large selection of insulation. Several varieties stand out against this background.

Mineral wool

Mineral wool is a common textile fiber produced by various methods. Fiber made from volcanic materials is called stony fiber. Slag wool is created on the basis of blast furnace slag. Glass wool is a raw material created on the basis of glass melt. As for the thickness of the insulation, the indicator ranges from 2 to 20 cm.

Mineral wool is optimally hygroscopic; over time, it degrades as a result of condensation. To prevent this process, when installing the insulation, it is necessary to mount an additional layer of vapor barrier.

Polyethylene foam

Polyethylene foam in the form of a roll on a foil base - a new generation of insulation.The thickness of such a material ranges from 3 to 20 mm. Polyethylene foam is the most effective material used for ceiling insulation. Small thickness makes it easy to install in a private house and apartment.

Styrofoam

Polyfoam is a material made of plastic mass in the form of cells. It is produced in the form of squares with a size of 1 x 1 m. The thickness of the sheet is from 2 to 10 cm. The density of the material varies between 15-25 kg / m2 (for insulation of the ceiling, 25 kg / m2 foam is often used). Polyfoam is often used to insulate suspended frames, walls and other coatings of a private house. It has good reviews.

Expanded polystyrene

Extrusive polystyrene foam is formed by the production of special polymers: the finished insulation is created by extruding the material through a special mold measuring 120x60 cm. The thickness of the finished sheet ranges from 10 to 200 mm. For insulation of ceiling structures, material with a density of 25-45 kg / cm2 is often used. In simple terms, this is foam made using a different technology. Its main difference is the higher strength of the material.

Expanded polystyrene (polystyrene) should be used as a ceiling insulation when subsequent plastering is planned.

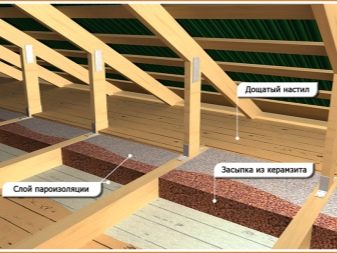

You can insulate the ceiling with loose expanded clay. This material is often used to insulate attic floors. In addition to the basic materials, insulation can be carried out with isolon, penofol, penoplex. It is important to fix the insulation material correctly. Materials are suitable for insulation on the top floor, veranda, basement, attic.

Which to choose?

Stopping at the choice of insulation, special attention should be paid to flammability, strength, weight and level of permeability. The cost of the insulation is not as important as its effectiveness. There are wooden and concrete floors. Concrete structures, in contrast to wooden ceilings, have a high load-bearing capacity. Concrete is considered a partially vapor-permeable material, but finished slabs lose this indicator.

Wooden ceilings are more common in private homes. Usually attic floors are installed on a wooden base. It is known that wood is susceptible to burning and passes any vapors well. If you try to close off the air, over time, the tree will begin to rot. It is worth highlighting the key factor affecting the choice of material - the location of the insulating layer. The ceiling can be insulated from the attic side of the house and from the inside. For lovers of an inexpensive, simple and affordable option for insulation, the attic floor is suitable.

Work technology

Experienced experts do not recommend insulating ceilings in the interior of the room. The main reason is the danger of penetration of insulation or its vapors into the room. Consider the best options for the placement and installation of ceiling heaters, observing the technology of work and precautions.

Expanded polystyrene (EPS) can be used as an effective option. Installation work begins with the installation of the battens. At the next stage of work, polystyrene foam is installed. The insulation thickness should be 3 mm.

Next, measure the space between the slats (no more than 2 mm). The empty space is filled with insulation and fixed with dowels. At the end, drywall is fixed to the crate as a suspended ceiling. Alternatively, tensioning structures can be installed.

Foamed polyethylene is not as effective as insulation. It can be used for insulation in the event that heat loss is small. A crate is mounted on the ceiling and penofol is fixed with dowels. After installation, on both sides of the material, a small gap is made for air ventilation and another crate is installed.

At the end of the work, plasterboard or stretch ceiling is mounted.As an alternative, penofol is recommended to be used in combination with penoplex.

Plaster mixes can become additional insulation. They are excellent insulation for concrete ceilings. Plaster mixes are highly environmentally friendly. They do not burn and fit perfectly into the architectural style of the house. One of the most natural and high-quality materials for insulating the interior with your own hands is an agglomerate of cork bark. A similar material is mounted on the crate. Since the bark of the cork is not afraid of moisture, a vapor barrier is not necessary.

Insulation of the ceiling in the interior of the room directly depends on the material used. Using polystyrene, the lathing can be omitted, since it is perfectly mounted on mastic or glue. Additional strength to the rest of the materials is formed by a hinged structure. In rooms of a wet type (for example, a bathroom), a metal profile is additionally used; in other situations, a wooden structure is used. However, it will not be possible to insulate the ceiling without decorative trim.

The profile must be fixed to the dimensions of the insulation. A film or glassine is used as a waterproofing material. The insulation is mounted without additional gaps. Another layer of waterproofing is placed on top of the insulation and glued hermetically. Foil insulation is mounted with a reflector in the interior of the room. A special lathing serves as an additional support element for the subsequent decorative finishing of the ceiling.

Tips & Tricks

Stopping at the choice of insulation, it is necessary to take into account the tips and recommendations, as well as a number of conditions and characteristics of the main material. In more detail, you should analyze the material of construction (concrete, brick, wood), as well as the size and purpose of the room.

Let's highlight the main properties and characteristics for ceiling insulation:

- High level of fire safety (material should not burn).

- The elasticity and resilience of the material play an important role in the preservation and restoration of the insulation.

- Environmental friendliness of the insulation (the main composition of the material should not contain harmful and toxic substances).

Do not forget about the recommendations for the installation of insulation. The heat-insulating layer of the insulation should not impede air circulation.

The durability and long period of operation of the insulation depends on this. Insulation of ceiling structures in private houses is carried out upon completion of the main construction work.

Before starting finishing work, it is necessary to insulate the walls and flooring. The main process of thermal insulation is carried out after the construction of the house. The structure must be fully seated (this happens within 6 months). After this period of time, the roof of the house is insulated. At the end of the work, insulation materials with waterproofing are mounted on ceiling structures. Experts recommend leaving a small gap between the insulating material and the roof for air circulation.

Insulation of a private house is a rather laborious work that can be done by the efforts of several people, subject to competent installation technology, installation, as well as the choice of material.

The finished ceiling structure can reduce heat loss by up to 10%. As a result, the owner of a private house will significantly save on heating, will feel cozy and comfortable being indoors. The process of warming requires diligence and responsibility. A cozy atmosphere in the house will depend on the efficiency of the work performed. If there are certain doubts and uncertainty about one's own abilities, the insulation of the ceiling should be entrusted to experienced specialists.

From the video below you will learn how to insulate the ceiling in a private house.

The comment was sent successfully.