Ceiling in a private house: how to insulate from the attic side?

If the house has an attic, then it should be insulated, because any owner is ready to fight for warmth in his house. Therefore, the process of arranging the ceiling from the attic should be taken with full responsibility and must be done correctly.

Features: pros and cons

According to the famous canon of physics, warm air moves up to the ceiling. Therefore, with a "cold roof" and an insufficiently insulated floor, the heat goes out. This is called the term "heat loss". 25-40% of the heat can go through the roof from the house. In order not to heat the street, it makes sense to carry out thermal insulation work.

Ceiling insulation performs several functions at once:

- keeps the heat inside the rooms during the cold season - the air heats up and rises, but does not find "loopholes" to exit and again descends, remaining inside the house;

- prevents the penetration of heat in summer, therefore, a favorable microclimate with an optimal temperature regime is maintained in the room;

- minimizes the penetration of unnecessary noise, maintains peace and quiet in the house during wind, rain or storm.

All work on insulation requires preparation, because the illiterate use of insulating materials and non-observance of the technology, at best, will lead to the appearance of condensation, and at worst, it will create a real threat of fire in the house.

Below are the features of the materials used for insulating floors.

Types and materials of insulation

Traditionally, the following is used for thermal insulation of the attic:

- basalt mineral wool or fiberglass;

- Styrofoam;

- polyurethane;

- expanded clay, vermiculite and other bulk materials;

- ecowool.

Often, homeowners use traditional methods of warming using sawdust and straw mixed with clay.

Insulation materials differ greatly in their performance characteristics., and their prices vary in a fairly wide range. That is why you need to consider each group of materials separately.

Sawdust

Thermal insulation using sawdust is one of the old ways of warming a room. Sawdust is used in those regions where woodworking industries are widely developed, where material can be purchased almost for free.

It is the availability and low cost that have become the main advantages of the material.

Of the minuses, high flammability should be noted. However, this shortcoming is easily compensated for by the competent use of modern installation systems. Another disadvantage is that sooner or later rats and mice will "take a fancy" to wood chips. To avoid such an undesirable neighborhood, sawdust is mixed with lime, which scares away rodents.

Mineral wool

Mineral wool is used to insulate the attic space, ceiling, facades, balconies and loggias.

This material has excellent consumer properties and has many advantages:

- relatively low cost;

- ease of installation;

- unsuitable for food for rats and mice;

- low flammability.

Along with the advantages, mineral wool also has disadvantages:

- cotton wool should not be pressed - its effectiveness may decrease by 30-40%;

- the properties of the material deteriorate when wet, because if the roof leaks in the house, then moisture will begin to accumulate in the insulation, which will not only worsen its properties, but will also become a favorable breeding ground for fungi and mold;

- the insulation cannot be used in a house where people with asthma and other diseases of the respiratory system live.

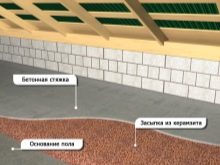

Expanded clay

Simple and durable insulation.

Its advantages are obvious:

- light weight;

- low thermal conductivity;

- environmental Safety;

- resistance to low temperatures and combustion.

The use of expanded clay does not require special technical training, because in order to carry out work on the insulation of the ceiling, it is enough just to cover the treated surface with this material, having previously laid any vapor barrier layer.

Expanded clay is suitable for installation in attics with a large number of pipes and ceilings.

Expanded polystyrene

This is the same styrofoam. It is well known to everyone, it is widely used for quick and effective insulation of ceilings and facades of buildings. Working with polystyrene is simple: for this you need to make accurate measurements and not cut off excess material from a solid sheet.

The advantages of expanded polystyrene are:

- light weight;

- it is easy to cut;

- it is resistant to moisture and temperature extremes;

- has low flammability;

- environmentally friendly;

- not a breeding ground for mold;

- not used for food by rodents;

- has a low cost and availability.

Styrofoam should not be used in an attic with a large number of pipes, since in this case the covering will simply have to be folded like a puzzle.

Polyurethane foam

It is a special sprayed material. Its application requires special skills and professional equipment.

The material is mainly used in harsh climatic zones - this is due to its extremely high performance characteristics:

- polyurethane foam fills any gaps, forming a seamless sealed coating;

- freezing, forms a dense layer on which you can walk without fear of the appearance of dents;

- due to low rates of thermal conductivity and water absorption, the insulating properties do not decrease at any temperature and humidity level;

- does not require preliminary use of heat and waterproofing materials during installation.

Of the minuses, it is possible to note high manufacturability, because working with polyurethane foam requires professional equipment and special work skills.

Ecowool

It is a relatively new material composed of fine cellulose fibers.

Among its advantages are:

- light weight - ecowool can be applied in any layer, without fear of making the attic floor heavier;

- safety - the insulation is made from environmentally friendly raw materials, does not contain harmful and toxic substances;

- is an unfavorable breeding ground for mold and fungus due to its "preserving" properties;

- retains extremely high performance properties over a long period of operation;

- low flammability and self-extinguishing ability.

Which to choose?

Below are some guidelines that will help you decide on the right choice of insulation for the attic in a private house:

- If you plan to engage in thermal insulation on your own, then you should give preference to expanded clay, foam or mineral wool. For work with ecowool and polyurethane foam, specialized equipment and some technical training are required - these materials are best entrusted to professionals.

- If the attic floor is made using reinforced concrete slabs, then it is optimal to use expanded clay as insulation, but it is more expedient to protect wooden floors with mineral wool or cellulose wool, since these materials are considered "breathable" and they prevent the formation of condensation, as well as the destruction of wood.

- It also significantly affects the choice of material and the planned budget.For example, if the owner of the house has access to sawmill waste, then you can simply use sawdust and shavings - this will be the most environmentally friendly and at the same time the cheapest way of thermal insulation.

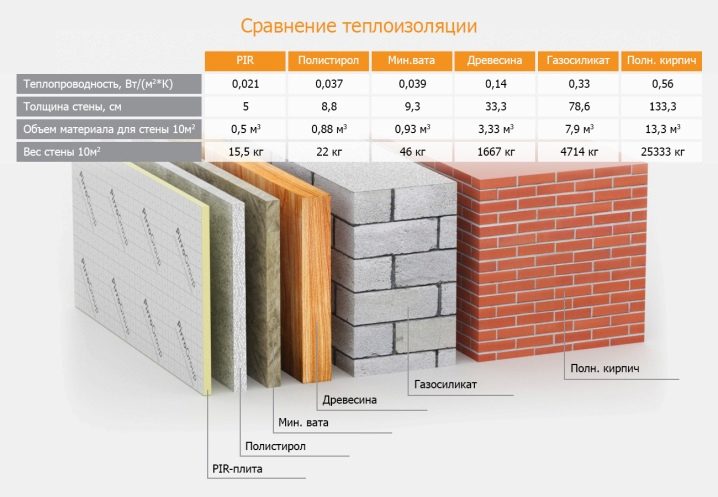

How to calculate layer thickness?

To calculate the thickness of the required insulation layer, special calculations should be made. It won't be too difficult if you use an online calculator. In general terms, the calculation scheme is based on the physical parameters of the substances and the established building codes.

For example, in Moscow SNiPs established that the insulation of all types of floors should provide resistance to heat transfer, R = 4.15 m2C / W. When foam with a thermal conductivity of 0.04 W / mC is used, the required coating thickness is calculated as follows: 4.15 x 0.04 = 0.166 m. Polyurethane foam will require a layer thickness of 125 mm, and expanded clay must be taken 415 mm in height.

Work technology

The technology of thermal insulation works directly depends on the type of material used.

Bulk materials

The technology for working with bulk materials is considered the simplest. To begin with, the ceiling is carefully cleaned, cleaned of dirt and debris. After that, a layer of hydro and vapor barrier is laid on the surface. Most often used "Izospan", aluminum foil, roofing felt or polyethylene.

The selected material is cut into strips and overlapped. On top of it, it is advisable to apply a layer of soft clay, after which the insulation is poured.

At the final stage, a mixture of sand and concrete is applied over the expanded clay and sewn up with floorboards.

Installation of slabs

When laying slabs (for example, foam), technical work is carried out in several stages.

To begin with, you should overlap the vapor barrier over the entire surface of the attic. After that, the plates are laid directly. At the same time, the most difficult thing is to cut them correctly, which is rather difficult, given the weak flexibility of the material and its flowability.

All gaps at the joints are filled with polyurethane foamto prevent the formation of cold bridges. Additionally, the entry points of ventilation pipes and electrical wiring are treated with foam. Another layer of vapor barrier is laid on top of the slabs.

Spraying

These works require special equipment and are carried out by professional teams in several stages. After the application of each layer of polyurethane foam, a foaming and stabilization stage takes place. As a result, the surface becomes seamless and sealed.

This is an effective method that allows you to carry out large volumes of work in the shortest possible time.

Helpful hints and tips

Each material for insulating the ceiling from the attic has its own advantages and disadvantages. The choice largely depends on the personal preferences of the owner of the premises, his financial situation and further plans for the use of the attic. Of course, it is better to give preference to environmentally friendly materials that will not cause allergies in households, will not pose a threat to the life and health of adults and children.

After insulation, the attic can be converted into additional living space, organize a pantry there for storing unnecessary things, or even make a small room. But this is at the discretion of the owner of the house.

For information on how to properly insulate the ceiling from the attic side, see the next video.

The comment was sent successfully.