The subtleties of ceiling insulation in a wooden house

In private wooden houses, as a rule, beamed ceilings are made. They are reinforced from below with boards for a secure stop. If the attic part of the house is not heated, the ceiling requires mandatory insulation. We will tell you how to do this in this article.

Peculiarities

From physics lessons, everyone knows that there are three ways of transferring thermal energy:

- thermal conductivity;

- convection;

- radiation.

When it comes to ceiling structures, then all three options are relevant. By convention, heat rises higher, and when heat is transferred from air to materials, the most heated gas is activated. Any designs have cracks and natural pores, so the heated air partially escapes along with the heat. Infrared radiation escaping from all heated objects in the room also contributes to the heating of the ceiling.

All this suggests that the greatest loss of heat in the house occurs through the ceiling, therefore, work on the insulation of the building should be started from this part. This can be done by choosing the right insulation material.

Materials (edit)

On the modern market there is a huge variety of insulation for the ceiling. When choosing a specific type of material, you need to know its characteristics and laying technology.

Ceilings in wooden houses are most often insulated:

- sawdust;

- mineral and ecowool;

- expanded polystyrene;

- expanded clay.

Each material listed has its pros and cons. Let's take a closer look at them.

Sawdust

The most environmentally friendly material for insulation is shredded natural wood. With a significant consumption of material, it is lightweight and does not affect the supporting structures of the house. Sawdust can be purchased at any sawmill for little money, and sometimes even free of charge. Of the obvious disadvantages of the material, it is worth highlighting its increased flammability. In addition, sawdust is an extremely unstable insulation, depending on weather and climatic conditions, it can dry out or, conversely, get wet and start to rot.

Mineral wool

The most popular material among buyers as a ceiling insulator in a private house. Its popularity is due to its low price, ease of installation and good heat retention properties. In addition, cotton wool has soundproof characteristics, does not require periodic replacement, and will last a long time. Of the minuses, it is worth highlighting hygroscopic properties, over time, cotton wool accumulates moisture in itself, which means that its thermal insulation characteristics deteriorate. It is also important to note that this is not the most environmentally friendly material.

Expanded polystyrene

Modern insulation, presented in the form of slabs. Plates are lightweight and safe, they look like polystyrene, but unlike it, they do not have increased fragility and do not crumble. The performance properties of expanded polystyrene are much higher than the properties of polystyrene, plates made of such material will last longer and will not lose their thermal insulation characteristics. High humidity is not terrible for expanded polystyrene. The disadvantages of the material include its high cost and flammability. It is also important to note that this material cannot be laid in a house where rodents are not bred. Mice easily gnaw through the passages in it, due to which the thermal insulation properties of the material deteriorate.

Expanded clay

Sold in the form of porous granules made from clay. The material is quite cheap, while it has good heat retention properties. An indisputable plus of expanded clay is its durability, the material will last many times longer than any other insulation. Neither water nor fire is terrible for expanded clay.However, it significantly makes the ceiling structure heavier when laying; it is important to pay attention to this factor if the house is not new.

Important nuances

Wood as a natural material itself has good thermal insulation properties. Therefore, with a sufficient thickness of the walls of the log house, they themselves perfectly retain heat inside the building. However, this does not mean that no other insulation material is needed. Heat escapes through the natural pores of the wood material, its significant losses occur precisely through the ceiling, since heated air is lighter than cold air, which means that everything rises above it.

The comfort of the temperature regime in the premises of the house will depend on how the insulation on the ceiling is correctly selected and laid.

Any material selected as insulation must meet certain criteria:

- fire safety;

- environmental friendliness;

- ease;

- low thermal conductivity;

- moisture resistance.

In addition, if the selected material also has soundproofing characteristics, this will provide a more comfortable living in the house.

The choice of insulation

When choosing an insulating material for ceiling insulation, you need to familiarize yourself with the main characteristics of each.

Materials can be bulk, slab, roll, block. According to the characteristics of the composition - organic, inorganic and mixed.

TO organic insulating materials include sawdust. And from a mixture of sawdust, peat and hay with the addition of cement, you can make a durable building composite. Sawdust is perhaps the oldest insulation used in the construction of houses. However, low refractoriness and wear and tear make this material less and less in demand over time. Organic insulation needs to be renewed periodically, which causes difficulties in the overhaul of the ceiling.

Inorganic insulation - expanded clay, obtained from clay with the addition of impurities by firing. In addition, this group includes mineral wool. Both materials are in demand in the construction market, while expanded clay is more popular due to its low cost and high thermal conductivity. An important point - a very large volume of expanded clay is required to insulate the ceiling, so it is advisable to lay it where the ceiling has a beam structure with a continuous roll.

Roll inorganic insulation - mineral wool is no less popular with builders as a heater; even a beginner can lay it down. The material has the best heat retention properties, it does not deform and does not wear out over time. In the last decade, mineral wool has been replaced by ecowool - cellulose with a special impregnation with antiseptics and refractory substances.

Polymer heaters inexpensive, durable and lightweight. This is the most modern type of insulation that has many positive properties. Of the disadvantages of these materials, it is worth noting the release of corrosive smoke when ignited, which has a detrimental effect on human health. But technologies do not stand still, and recently polymer insulation materials with increased refractory characteristics have been developed, which do not burn at all and do not emit any substances when smoldering.

How thick should it be?

The thickness of the ceiling insulation to be laid will depend on which insulation material has been chosen for installation.

The amount of sawdust required can be calculated based on building codes - the thickness of this type of insulating layer must be at least 20 centimeters.

Expanded clay embankment must have a thickness of 10 centimeters, you can lay a larger volume, moreover, the thicker the embankment, the better the insulation will be.

Mineral and ecowool - one of the most reliable ceiling insulation in a wooden house. For the best thermal insulation effect, the thickness of this material should be at least 15 centimeters.

And, finally, polymer insulation must have a thickness of 5 centimeters or more in order to perform well its functions of keeping heat.

How to insulate?

Insulation of ceiling structures can be carried out outside or inside. Which method suits you best will depend on the structure of the roof, on the repairs already carried out in the house, on the height of the attic and the ceiling itself. So, when carrying out work inside the house, you need to understand that the ceiling height will decrease. If you insulate the attic, that is, the ceiling of the house from the outside, then after installation it will be necessary to lay your own flooring there, otherwise there will be little effect.

Ceiling insulation works are best done during the warm season. - in spring and summer, so by the onset of cold weather, moisture, which is in any case contained in the material, will evaporate, which will improve the strength and insulating qualities of the structure.

The technology of ceiling insulation itself should not cause difficulties when using any material, since the main elements - wooden floors are already present, you just need to correctly distribute and fix the insulation on them.

The first thing that you should definitely pay attention to is that high humidity is destructive for wood, therefore, the insulation material must have waterproofing properties.

Before starting the installation work, you need to conduct a visual inspection of the ceiling structures for the presence of obvious cracks and holes, and if there are any, they must be closed using polyurethane foam. The foam instantly sets and hardens, a few hours after the application of the excess, it can be cut off with a knife and the entire surface is leveled with sandpaper.

Another important circumstance is the most common method of insulation with bulk materials: expanded clay leads to a significant weighting of the entire ceiling structure. In addition, it takes a long time to distribute the mixture evenly over the surface. More modern analogues of heaters do not need much time and labor.

Ceiling insulation works are carried out in three stages

First, it is required to provide the ceiling with waterproofing, for these purposes it is better to choose glassine, which is distributed over the entire surface in strips cut with the same width and length. You need to take so much waterproofing that 10 centimeters of material remain between the beams. It is imperative to lay the glassine with an overlap (about 15 centimeters), and at the joints, process with mastic.

At the next stage, the insulation itself is laid. For example, roll materials are easily attached to the base with self-tapping screws.

At the third, last stage, another layer of waterproofing is laid on top of the insulation. This technology is suitable for working with polymeric materials. If the work was carried out with bulk materials, then on top you will also need to lay additional attic flooring, for example, plywood.

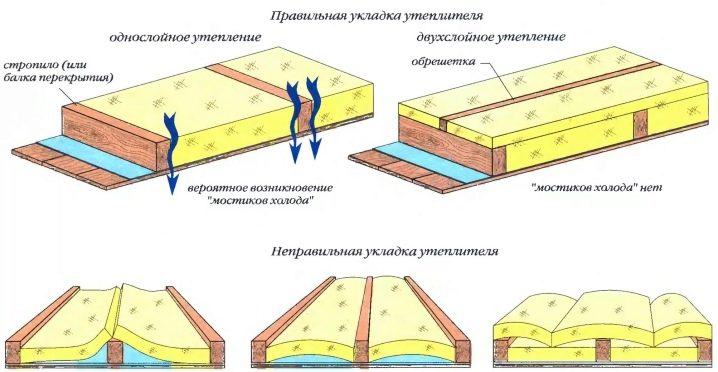

Mineral wool is laid in two layers so that the joints of the sheets of the lower and upper layers do not coincide with each other. The size of the sheet should be 2–3 centimeters larger than the distance between the beams. Cotton wool needs to be laid very tightly and preferably tamped. In addition, when working with this material, it is important to follow the safety rules: use a respirator and wear rubberized clothing that eliminates the static effect.

At the end of all the work, the insulated structures must be covered with PVC panels, and the attic itself can be sheathed, for example, with clapboard.

Tips & Tricks

To insulate the ceiling, there is a special ceiling tile made of foam, it protects well from the cold, but in the conditions of severe winters, it alone will not be enough, but you can still save on the main insulation and lighten the entire structure.

Insulating the ceiling alone will not lead to the desired effect, warm air will escape through any cracks found, therefore, walls with a floor also require thermal insulation.

If you have doubts about your own strengths and skills, it is better to turn to professional workers. An improperly insulated ceiling will not bring any benefit, and the craftsmen will do everything efficiently and quickly, based on their own experience and the requirements of building codes.

Plasterboard structures need fasteners with galvanized iron profiles, since the material itself is not able to hold its weight and without reliable support there is a possibility of it falling.

Well, you can insulate the ceiling with mineral wool or penoplex. For timber, these are reliable "companions" that can be used between floors. In a country house, insulation from the inside is very important, and it is quite possible to do it yourself.

At the construction stage, it is necessary to insulate the ceiling immediately, but if a ready-made house has been purchased and there is no insulation in it, it is necessary to carry out the work immediately after settling, having thought over the procedure and scheme of work in advance.

For the intricacies of ceiling insulation in a wooden house, see the following video.

The comment was sent successfully.