Features of the mini-tractor KMZ-012

The KMZ-012 model appeared on the agricultural machinery market in 2002. Until now, the unit competes with many new products, as it has good technical characteristics. The car belongs to the traction class of specialized equipment.

Device

The mini-tractor KMZ-012 can be operated on farms, in the utilities sector, at a construction site. The compact dimensions and reliability of the design allows the unit to easily carry out plowing, soil cultivation, cleaning household plots, hilling plants, shrubs and many other functions. Efficiency in the operation of the machine is advisable on an area with dimensions of no more than 5 hectares.

The machine has 2 dependent PTOs, as well as 2 attachments. Due to the presence of a lever-hinge device with a chain-type bar, as well as a traction fork, it is possible to displace the working tools to the right side up to 10 centimeters. The trailed beam can be displaced in both directions.

The mini-tractor does not have a cab, but in order to protect it from rain and sun, a roof can be installed. The place where the worker is supposed to be has a seat that reclines and contributes to the comfort of the user. Under this element is a battery-type battery, as well as a fuel tank. The undercarriage of the unit consists of a front wheel axle that looks like a swing beam.

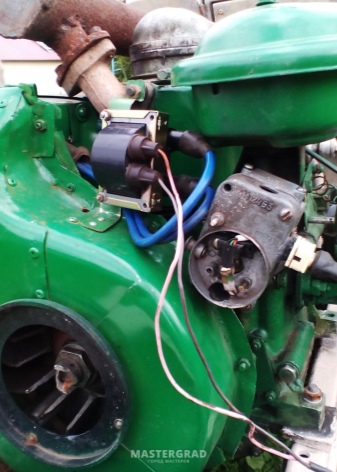

Brakes equipment using wheel brakes that are mounted on the housing of a 1-stage gearbox. The gearbox is responsible for the traction ability, in which there are 4 forward and 2 reverse speeds. The equipment of the transmission is expressed in a 1-disc friction clutch. In the hydraulic system of the machine, the operation takes place thanks to the drive from the engine, which is equipped with a power take-off shaft, as well as a hydraulic valve with a spool type.

Specifications

Mini-tractors KMZ-012 belong to machines with 0.2 traction class. The mini-tractor has several wheel drives located at the rear of the machine. The unit has the ability to change the track. This model is characterized by small dimensions, it has a width of 96 cm, a length without overhangs - 197.2 cm, a height without a roof - 197.5 cm. The weight of the car is influenced by its configuration. The average weight of a mini-tractor is from 650 to 750 kg.

The unit is equipped with a diesel engine with two cylinders and a V-shaped cooling system. There is also a modification that is equipped with an American gasoline engine. The carburetor type of the engine has two cylinders, its operation is based on gasoline. The Hatz 1D81Z engine has a single cylinder and an air-cooled system.

The advantages of the model include good power, which is 12 horsepower, as well as economical fuel consumption - 3 liters per 100 km. The fuel tank can hold 20 liters of fuel, so the user can work for a long time without stopping to refuel. Due to the presence of a clearance of 30 cm, the mini-tractor is easy to move off-road. The control levers make it easy to use the machine.

The advantages of KMZ-012 include the following characteristics:

- multifunctionality, universal application;

- ease of use;

- economy in fuel consumption;

- compactness and light weight;

- ease of repair and customization;

- availability of spare parts required for troubleshooting;

- low cost;

- convenience and comfort when driving a car;

- good maneuverability.

The disadvantages of a mini-tractor include the following:

- inconvenience in the location of the fuel tank;

- the dependence of the transmission on the hydraulic pump;

- low quality of the elements that are included in the gearbox.

Attachments

Rear and front hinges allow you to connect different types of additional equipment to the mini-tractor, for example, a milling cultivator, a front loader, a plow, a snow blower, a sweeping brush. Owners of KMZ-012 can improve the functionality of their unit thanks to different hinges. Let's list them.

- Harrows. This equipment contributes to a better plowing procedure than using standard cutters.

- Trailers, allowing to transport goods weighing up to 0.5 tons.

- Blade shovels, which are intended to remove snow cover, foliage, dirt from the site.

- Plows, which allows for more efficient excavation work.

- Lawn mowers. These hinges are capable of mowing weeds and wild vegetation.

- Tillersthat are able to work on dense soils.

- Grass collectors... This is a type of hitch that must be applied after mowing the grass, which is used for hay harvesting.

- Spreaders, which are used for scattering seeds, as well as for sprinkling sidewalks, roadways in the winter season.

- Redesigned snow blowers. This equipment is necessary for the cleanliness of the areas, which is achieved by removing snow and throwing it over a long distance.

- Brushes. This attachment removes not only snow, but also debris. It is often used in public utilities.

User manual

Before starting intensive use of the KMZ-012 mini-tractor, the user must run it in. This procedure consists in a set of measures that can significantly improve the operating ability of the motor, while allowing each of the large units to work in. When starting starts, it is worth observing the state of the engine. The work of the latter should not be intermittent and noisy. And also it is worth making sure that there is no fuel or oil leakage.

According to the manufacturer's recommendations, it is worth using SAE 10W30 oil, which should be changed according to the table in the instructions. At the first stages of running-in, the engine should be started at low speeds, without loads. The duration of this procedure should be about 70 hours. After this time has passed, you can put the unit at full load.

When running in, it is worth checking the fasteners and bolted connections. It is necessary to work out the power take-off shaft initially at an idle year, and then with low revolutions after an interval of 10 minutes.

Maintenance of the machine before the conservation phase involves a number of steps.

- Before starting to use, it is worth making sure that all clutches, brakes, as well as the steering system are in good working order.

- The engine oil needs to be changed every 50 hours of machine operation. In summer it is recommended to use M-10DM, and in winter - M-10V. Before starting the fuel change, it is worthwhile to warm up the engine. After this procedure, the oil will be more liquid, and the engine will get rid of it faster.

- The transmission oil should be changed once a year or after every thousand operating hours.

- If the unit runs on gasoline, then it is worth using AI-80 or AI-92 fuel. In this case, the oil must be characterized by freshness and purity.

- For the correct process of "conservation" of the mini-tractor does not require a lot of knowledge and effort. The storage room for the machine must be dry and well ventilated. You can purchase a special type of cover that will reliably cover the mini-tractor.Do not place your car near a fire source.

- Before preservation, the unit should be thoroughly washed, paying special attention to the metal elements. Do not forget to remove adhering dirt and dust. After removing rust, it is necessary to lubricate the parts with oily substances.

The oil and fuel must be drained to prevent condensation from forming. To prevent the liquid from freezing, it should also be removed from the mini-tractor. Tire pressure should be reduced by 30 percent.

In order for the service life of the mini-tractor to be long, the following measures are strictly prohibited:

- overload the unit;

- use the machine to perform tasks that are not typical for it;

- turn off the engine at high speeds;

- fill in oil and fuel that is not recommended by the manufacturer;

- carry out maneuvering operations while the attachment is lowered;

- carry out the transportation of passengers.

In order for the machine to function normally, it is worth adhering to the following rules:

- use only those fuels and lubricants specified by the manufacturer;

- clean and change filters regularly;

- correctly carry out the "conservation" procedure for the cold season;

- do regular inspection before each use;

- carry out maintenance according to the schedule specified in the instructions.

The most common problems with KMZ-012:

- decrease in power;

- increased fuel consumption;

- the appearance of black smoke while the motor is running;

- the occurrence of extraneous noise;

- excessive vibration of the unit;

- visually visible leaks from the oil or fuel tank;

- changing the functioning of the chassis;

- failure of the main systems.

In a situation where the attachment refuses to rise, it is worth adjusting the pedal free travel, replacing or cleaning the drive discs, and eliminating jamming in the discs on the splines. If the mini-tractor begins to malfunction during braking, then it is worth adjusting the free pedal travel, replacing the elements of the brake disc or pads. The gearbox may overheat if the gear clearance is too small or the oil quantity is insufficient. If the user began to notice that the starter does not function, then the reason for this could be an open starter, a poorly charged battery, a short circuit, or a poor contact of the magnetic switch.

Mini-tractor KMZ-012 is a multifunctional unit that can be used to solve many tasks on the land and in the garden. When using this unit, it is worth following the instructions, as well as troubleshooting in a timely manner.

For an overview of the KMZ-012 minitractor, see the following video.

The comment was sent successfully.