All about the wind and moisture protection membrane for the facade

Having learned all about the wind and moisture protection membrane for the facade, you can use it correctly yourself. Non-combustible membrane "FibraIzol NG" and products of a number of other brands are presented on the market. Therefore, it is important to find out which one to choose, and which side it should be put on.

What it is?

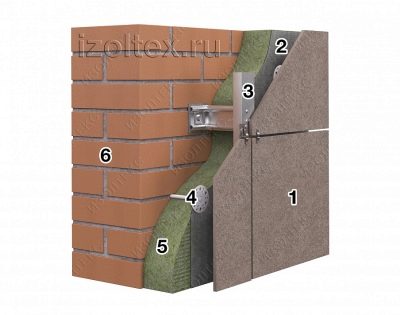

The use of membranes for the facade began relatively long ago. Such structures are used mainly in ventilated façade assemblies. They perform well because they protect the insulation and the outer wall from water ingress. This is not the end of their role, because along with waterproofing, protection against weathering, leading to a thinning of the insulating layer, is also very important. Therefore, experts mainly talk about wind and moisture protection coating, and prefer it to less universal solutions.

Until recently, such protective films were created on the basis of easily flammable materials. Flames will spread quickly within the room with any fire. This has led to sad consequences more than one hundred times.

Therefore, in recent years, preference has been given to innovative non-combustible membranes. Both domestic and foreign firms are engaged in their production; the choice of specific options is quite large.

In general, moisture-proof properties can be described very simply - just as the use of a hydrophobic material. But wind protection is a much more tricky thing, even from the point of view of a professional. The composition of the combined protective material contains at least 2 layers. When the film (membrane) is heated, no harmful or hazardous substance will be released. Such structures guarantee a full-fledged microclimate in the building, protect the walls from the effects of dampness and bad weather, including the occurrence of mold and other fungal infections.

Materials (edit)

Various materials can be used in the production of windproof membranes. In the ultra-budget segment, glassine and polyethylene stand out. Their service life is short. Such products are mainly suitable for temporary protection of building structures. Yes, and you can only call it incombustible - if these materials do not spread combustion, then they themselves are destroyed by heating very easily.

Superdiffusion films have a multilayer structure. The fibers of a special polymer are taken as a basis.

Such a product is very permeable to water vapor. Subject to proper installation, the service life will exceed 25 years. Wind protection at a very high level.

For the purpose of finishing, PVC-based film membranes are actively used. They are very economical and practical. Reinforcement is rarely practiced. The lower part of the structure consists of polymer, to which a certain amount of dyes is added. PVC membranes are resistant to acid-base solutions and their salts, can be successfully applied in direct contact with any type of soil and are easily attached, regardless of temperature.

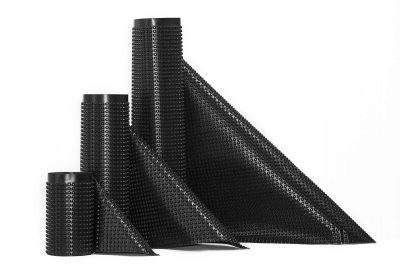

The profiled membrane, along with protection from wind and water, also serves as a wall drainage system. It is usually made on the basis of high density polyethylene. The starting material has rounded shaped protrusions. Thanks to him, the pressure from the external environment will be distributed uniformly.

Profiled membranes:

-

elastic;

-

tolerate contact with a wide range of aggressive media;

-

they work confidently not only on vertical, but also on horizontal surfaces;

-

mechanically strong;

-

remain flexible at low temperatures;

-

little subject to deformation.

The largest list of advantages is possessed by universal membranes. Their high cost is justified by the possibility of operation for 45-50 years. Such solutions have shown themselves well in multi-storey construction and even in the design of frame ceilings.

They confidently resist ultraviolet radiation. Strong wind for such a film is also almost at ease.

Top manufacturers

Firm "TECHNONICOL" can supply reinforced superdiffusion membranes. They consist of 3 layers and have microscopic pores. Non-woven polypropylene is placed above and below, which becomes the frame. In the middle there is a polypropylene film. Its feature is the passage of water vapor with cut-off of liquid water.

Other points:

-

standard length 50 m;

-

width 150 cm;

-

density 0.15 kg per 1 sq. m;

-

elongation at breaking force in length and width - 60%;

-

steam permeability - 1 liter in 24 hours;

-

the ability to survive 4 months under the influence of ultraviolet rays.

A non-flammable waterproofing membrane with an additional option of wind protection was created at the Khrunichev State Research and Production Center. "FibraIsol NG" suitable for the protection of insulation and the main structures of buildings. It is often used in hinged ventilation facades. The material is able to withstand heating up to 1200 degrees and does without fire protection strips made of steel. "FibraIsol NG" is useful for work in close to extreme conditions.

Under such a membrane, insulation will be reliably protected from:

-

fiber emission;

-

destruction of binding components;

-

rainfall.

The alternative turns out to be membrane Tyvek... It reliably prevents leaks and the ingress of condensation. The vapor permeability of the material is quite high. The corresponding nonwoven fiber was developed back in 1955, and a waterproofing product based on it has been used since 1990. It is already ISO 14001 and ISO 9001 certified.

Tyvek products can be laid directly on thermal insulation and framing elements. They are resistant to ultraviolet radiation for 3-4 months. The permissible temperature reaches 100 degrees. The ability to dispense with an additional counter grill allows significant savings. The structure of the product is completely unique and is a trade secret of the company. The protection layer reaches 450 microns - at least 6 times more than most common coatings.

In 2012, a new material appeared - Firecurb housewrap... It is suitable for waterproofing and windproofing buildings with different heights. This coating is self-extinguishing. Even with a severe fire, it emits little smoke. The fire safety level meets the requirements of Euroclass B both for free installation and when fixed on mineral wool.

A non-flammable membrane with water and wind protection is also available under the brand name Izolteks... It is produced by the Ayaskom company, which has its own modern production facilities. Izoltex NG200 is white by default.

But there is also a black variety, the color of which is associated with the use of carbon filler. This solution works well if the facing material has clearly visible gaps.

Model NG200 metallized is distinguished by an aluminum layer on the inside. This layer reflects heat in the same way as in a thermos. As a result, the efficiency of facade insulation increases. The technological process is developing steadily. And modern Izoltex options are no longer susceptible to particular fragility, which makes it possible to speed up installation work and improve their quality.

How to choose?

One of the key characteristics of a facade wind and moisture protection building membrane is its density.Normally, this figure is at least 0.09 kg per 1 sq. m. At this level, leaks and fluid seepage are excluded. A material with similar properties is also quite difficult to damage.

But at the same time, tensile strength is analyzed separately in many sources. It is divided into indicators in the longitudinal and transverse planes. The membrane for a ventilated facade on an insulated type of substrate must be well permeable to steam. Indicator less than 1 liter of steam per 1 sq. m is completely unacceptable. Only at a high level of this parameter can a quick release of water vapor to the outside be guaranteed. There are also a few more important criteria:

-

resistance to ultraviolet rays (it allows you not to be afraid that for some time the final cladding is missing);

-

lack of toxic properties and toxic fumes;

-

economic expediency;

-

duration of use (and by the sum of these properties, superdiffusion membranes are usually preferred).

Installation nuances

Which side to put, you need to find out in relation to each specific brand separately. Usually the smooth side is oriented towards the insulation. It is useful to cut the roll into fragments of the required length before installation, and make a careful marking. The installation itself goes from bottom to top with a certain overlap.

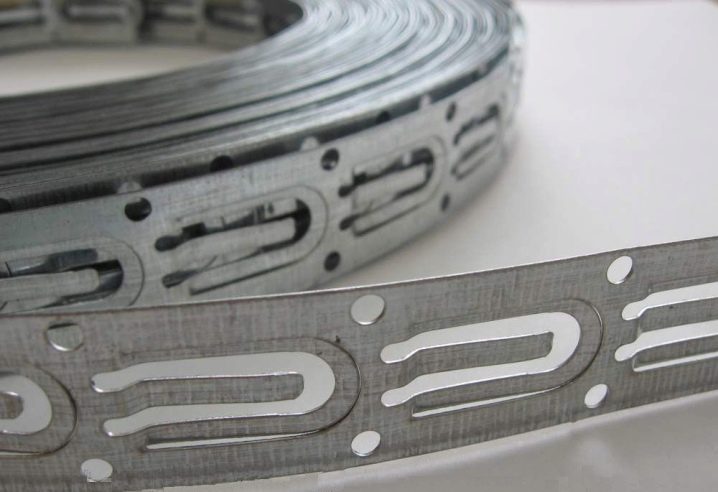

An assembly tape is needed to seal the joints.

Any holes are strictly unacceptable. All intersection points are supposed to be hermetically sealed. This is ensured only with a competent alternation of canvases. The overlap should be at least 15 cm. The use of a construction stapler is recommended for fastening. The assembly also includes cladding, counter-batten, additional insulation material.

The comment was sent successfully.