Profiled membrane: types and purpose

Profiled membranes are an indispensable material in construction that has become widespread. In the article we will tell you what it is, what are their features, types, manufacturers, areas of use.

Peculiarities

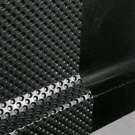

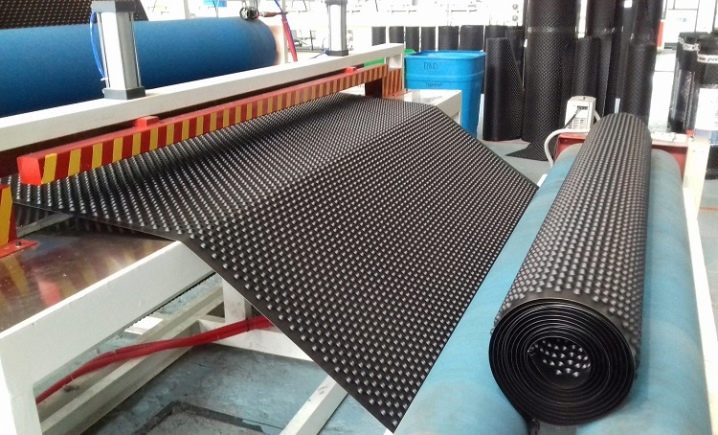

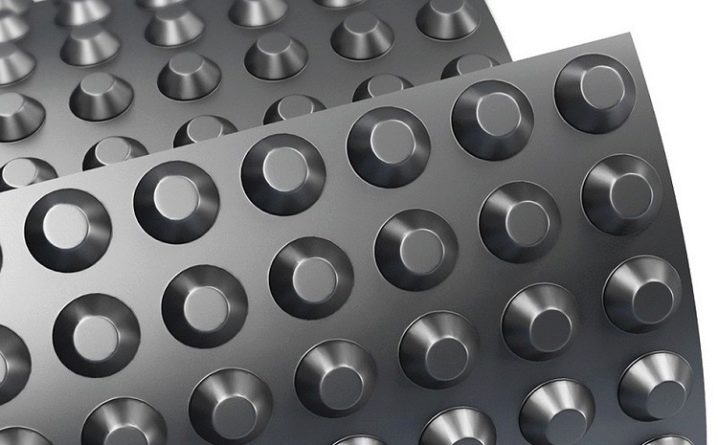

Profiled waterproofing membrane (PM) is a protective insulation in the form of a rolled high-density canvas. It is made of polyethylene (PVP) and has molded hollow spikes in the form of truncated cones or star-shaped protrusions. They are equally spaced. Moreover, their sizes are variable: the height can vary within the range of 0.4-10 mm. The density is 400-1000 g / m2, the width is 0.5-3 m, the length is 20 m, and the thickness is 3-5 mm. The main function of the profile membrane is to provide water drainage. It is produced in accordance with GOST standards and consists of antioxidant components, minerals and polymer additives.

She has a structural structure and high elasticity. The material is inert to the effects of various aggressive media. The type of the main filler determines its performance properties.

The profile membrane is an obstacle to water penetration on vertical and horizontal surfaces. It is mechanically strong, resistant to deformation, and has sufficient flexibility at low temperatures.

Specifications

The profiled membrane is produced according to the extrusion principle. Thanks to its relief, it creates a gap for condensation drainage and ventilation. At the same time, it reduces the volume of noise between structures. Its mechanical resistance (compressive strength) is 15-40 t / m2. The greater the thickness of the membrane sheet, the higher the resistance of the material to compression and rupture, bursting and stretching.

Profile membranes have minimum water absorption rates (less than 1%). Their cultivation capacity is 2.2-5 l / s * m2. Particularly powerful drainage varieties are geotextile options. The average roll weight is 24 kg. Price - from 70 rubles per 1 m2. The service life of the canvases reaches 50 years. The membrane is an alternative to granular drainage materials.

Thanks to this, it is possible to save and speed up construction work. The insulator is inert to UV rays, mildew and mold. It is used at any time of the year with different humidity. It is easy to operate, does not need an open flame, and has a welded thermal layer. The corrugated surface promotes high adhesion.

These materials are durable and productive. The canvases do not sag, do not block the air gap, exclude silting of the drainage cavity and its clogging with solid particles. The canvas can be glued. Due to its composition, it does not lend itself to destruction due to water and tree roots. Its only drawback is its high cost. However, it is justified by the quality and durability of the building material.

Application area

The areas of use of profile membranes are different. For example, they are used to protect foundation waterproofing. Lay on top of a waterproofing layer to prevent contact with the ground, instead of concrete preparation of paths around the house. They are a preventive measure against possible soil displacement, shrinkage, exposure to aggressive chemicals present in the composition of groundwater.

In addition, the material protects the waterproofing from moisture due to melt, rainwater. Prevents its destruction due to trench filling at the end of construction work.The membrane layer perfectly preserves the concrete base near the house, near which trees with overgrown roots grow.

The material can be laid not only on a mastic, but also on a glued type of waterproofing.

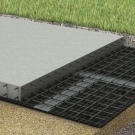

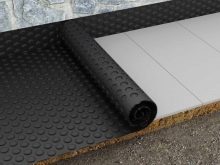

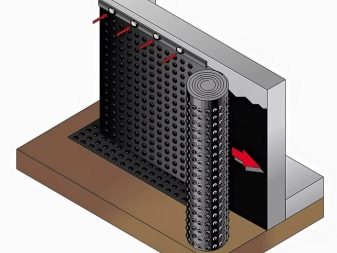

Another purpose of profile membranes is the arrangement of drainage systems near the walls. The canvas is laid with a relief upward, protecting the walls of the foundation from moisture due to atmospheric precipitation. The relief texture increases the drainage effect. Thanks to it, the water flow into the deep layers of the soil is accelerated. This does not create pressure on the walls, reducing the likelihood of leaks.

The technology of laying profile membranes of the wall drainage system involves installation along the foundation perimeter. Backfilling is carried out using ordinary land, which reduces the cost of construction. The profile membrane is used to provide filtration of the water runoff. For this, a variety with geotextiles is needed, due to which the likelihood of silting is excluded. In addition to the installation of waterproofing, plastering work on the basement, the arrangement of the roof, floors, profiled membranes are used to create ventilation of building objects.

The membrane can be attached to the buried walls of the foundation, plinths, structural elements exposed to moisture. Installation is possible both inside and outside the wall. In the first case, the membrane sheet must be fixed with the smooth side to the wall ceiling. A layer of plaster is made on top of it, or plasterboard sheets are mounted. Installation is carried out in such a way that air can circulate freely from above and below. Therefore, small gaps are left.

When the membrane is fixed from the outside, it should be spiked against the wall. Water evaporation is carried out due to the space between the pins. A profile membrane is needed for arranging the blind area. To do this, it is laid horizontally along the perimeter of the structure with a slope towards the ground. This ensures an effective drainage of water from the walls. And the likelihood of heaving due to frost also decreases. After that, gravel, soil filling is performed, paving slabs or other facing are laid. Such a blind area serves for about 50-60 years.

With the help of profile membranes, they equip road, garage, basement coverings. They are used to strengthen underground passages and cellars.

Varieties

Materials can be classified according to various criteria. For example, the thickness of the materials determines their purpose. Canvases with a minimum thickness of 0.4 mm are used in private housing construction. Analogues with a thickness of 0.6 mm organize wall drainage, blind areas, they are bought for work on objects with deepening or heaving soil. Thicker products are used in industrial facilities.

The height of the studs determines the rigidity of the canvases and the type of ventilation gap, the peculiarities of working with wet underground structures. At the same time, their flexibility remains even with strong soil freezing (up to -45 degrees). The profiled diaphragms differ in the design structure. Each species has its own characteristics. A common feature is the base material.

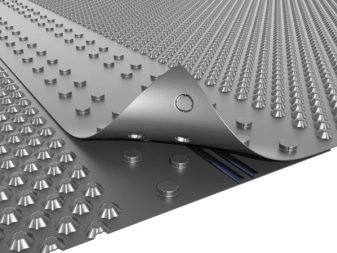

Single layer

This type of membrane is the thinnest. The thickness of a single layer can be up to 1 mm. In this case, the height of the studs is 7-8 mm. Products assume a horizontal arrangement. Single-layer profile PVC membranes are a means of auxiliary waterproofing. They protect the existing layer from damage and contribute to the correct distribution of the mechanical load.

Double layer

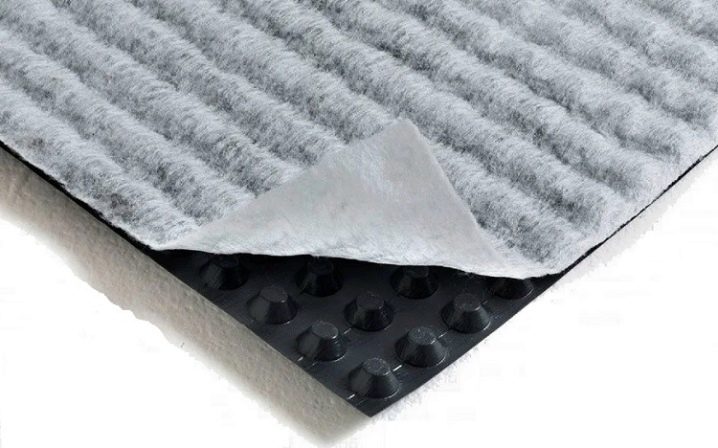

In addition to the main layer, the material has a thermally bonded geotextile coating. This is the traditional version of membranes used as a groundwater filter.... In comparison with the previous type, such building materials are especially tough and durable. Membranes of this type are used when arranging wall drainage.

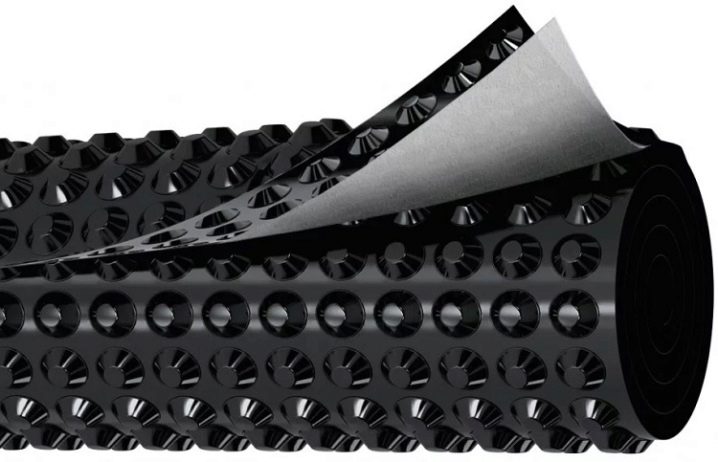

Three-layer

A distinctive feature of this variety is the presence of a polyethylene film coating. It has a smooth and sliding texture, it is this side that should be located against the wall. Such varieties are used for deep laying of the foundation. They are also used when arranging a wall drainage system. They are used when working in heaving soil.

Nuances of choice

There are a few basic things to consider when buying a particular variety. The key one is purpose. In addition, attention is paid to the conditions of use of the material. An important criterion is the type of soil, as well as the depth of the foundation to be laid. The type of soil determines the degree of lateral pressure on the profile membrane sheet. Because of this, it shrinks, which further reduces the culvert capacity. Products have a different mounting method. Its fastening elements are dowels with a profile washer. And also for fixing, laminated adhesive tapes, latches, clamping strips are provided.

You need to choose products from a trusted supplier with a good reputation in its segment.

The parameters of a standard roll are 2x20 m. On sale there are options with a single mechanical lock. The wrong choice can lead to gross technological disruptions. Geomembranes are of two types: LDPE and HDPE. They differ in the type of polyethylene pressure... They also have different characteristics. The operating temperature range ranges from -60 to +80 degrees. HDPE has higher values of density, tensile strength, hardness, flexural modulus. LDPE has significantly higher tensile elongation.

Popular manufacturers

Leading companies in Russia and other countries are engaged in the production of profiled membranes. Among them, it is worth noting the products of several brands, which are highly appreciated by customers.

- TECHNONICOL offers buyers material PLANTER made of high density polyethylene with molded rounded protrusions. The rolls are 1, 2, 3 m wide, 10, 15, 20 m long. Popular modifications are PLANTER EXTRA, PLANTER ECO and PLANTER Geo. The planter has high mechanical strength. It is laid vertically and horizontally.

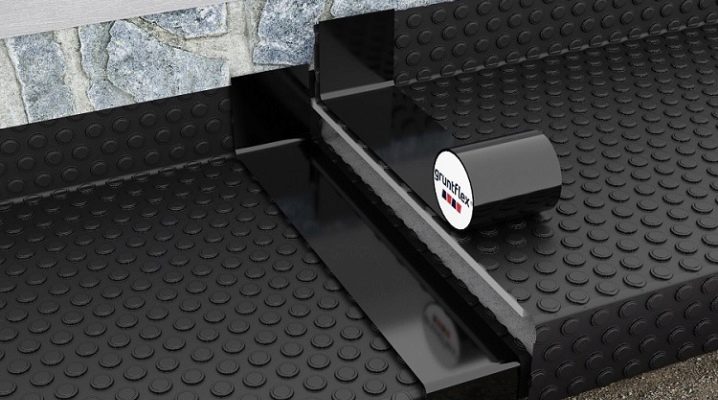

- Gruntflex offers professional profile membranes for private construction: Fundament Bace, Landshaft, Drenaj, Heavy Duty 450 width 1, 2 m, roll length 10, 15, 20 m. The brand's products have zero water absorption, a large number of protrusions, high compressive strength. It can be used at depths of up to 10 m. It has high breaking strength in longitudinal and transverse directions.

- LockDown supplies material to the domestic market Standard size 2x20 m, projection height 7.5 mm. The material is used in the construction and reconstruction of highways, slopes. It is suitable for work in difficult hydrogeological conditions. With its help, the concrete preparation of the base is replaced. The raw material for production is high density polyethylene granular, to which antioxidants and carbon black are added.

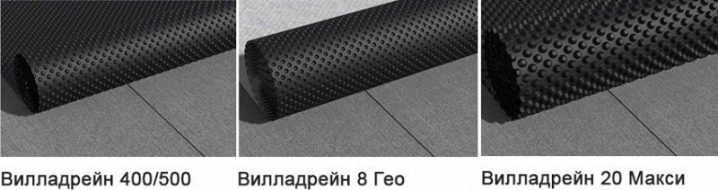

- "VILLADRAIN 400" - profiled membrane fabric of roll type with free laying and mechanical fastening to the base. The material has standard dimensions (2x20 m). Its thickness is 0.45 mm, the mass of 1 kg / m2 is equal to 0.4 kg. It is delivered on special pallets, packed in plastic wrap. The material has optimum compressive strength.

The comment was sent successfully.