Diaphragm water pressure reducers

Water supply as a system has many installation nuances, one of which is the correct distribution of pressure, which is extremely important in apartment buildings. To avoid problems with water consumption and system wear, pressure reducers are used, represented by diaphragm models.

general description

Water regulators are devices due to their operation, the normalization of the pressure in the water supply system is achieved. Due to this, the likelihood of failure of plumbing equipment is reduced, and a certain temperature level is maintained. Often the cause of malfunctions in the domestic water supply can be a change in the operation of the gearbox. The material for the manufacture of these products is brass, which has all the characteristics for this area of use. It is reliable and allows the gearboxes to last as long as possible under constant loads.

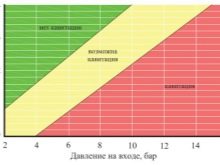

The principle of operation is to use an adjustable valve to limit the cross-section of the water supply and allow it to pass liquid in certain situations... At the moment, the types of operation by the type of restrictions exist in two types. The first one is static.

Recommended for use in situations where uneven and inconsistent water intake occurs. Such reducers maintain a given pressure in the network after their work and are most often used in apartment buildings, cottages and other places where water consumption is variable and not so voluminous.

The second type of diaphragm gearbox operates on a dynamic principle. It gives a head distribution that is constant with a continuous flow of water. This system is most often installed in production, where technical devices, machines, units and other products may require a large volume of water. Also, dynamic diaphragm reducers are widely used to maintain the operation of irrigation systems and irrigation of agricultural areas.

The spring-loaded part of the structure allows it to be versatile in a variety of situations. For example, when the pressure is too low and the devices connected to the water supply system stop working, the technique makes it possible to normalize the situation due to the active operation of the pump.

It increases the water flow rate and it starts to be enough for all the units requiring it. When the pressure is not constant, this leads to temperature jumps, which is undesirable for the water supply and its elements. The diaphragm reducer will allow you to achieve more stable performance, thereby minimizing damage to the system.

With excessive pressure, all parts of the water supply experience an extremely serious load, which, as a rule, manifests itself in various defects in the integrity of the connecting parts. Water hammer can cause leaks and malfunctions in equipment connected to the system and consuming a certain amount of water.

Comparison with piston gearboxes

Often, before buying a gearbox, the question arises of which type of product is better to choose. Here you need to look at what are the scope of the unit and the potential operating conditions. To better understand this, it is necessary to draw parallels between the two types of gearboxes and highlight their pros and cons. Due to this, the consumer will be able to more accurately select the product.

Diaphragm reducers at the heart of the design have a direct spring operation, which compresses or expands, thereby allowing the valve to change the amount of water supplied. Piston models do the same with the movable parts of the piston, and the movement itself is mechanically more intensive, so the wear of the diaphragm gearboxes is less significant.

It is impossible not to say about the working conditions, because piston products are more dependent on the quality of water and its purity. If the gearbox chamber is in contact with small particles, debris and other costs of water filtration, then they can hinder the operation of the valve, then it will have to be cleaned. Membrane models are not subject to this, since the absence of rubbing parts makes operation independent of dirt in the water supply system. The design of piston gearboxes is complicated by the presence of seals and gaskets, which wear out rather quickly and need constant replacement.

For membrane analogs, the chamber remains dry, so maintenance costs will not be so significant. But the disadvantage of this is the extremely high requirements for the material of manufacture of the membrane. As a rule, they are triple ethylene-propylene rubber or TEPK.

If it does not meet quality standards, then such a gearbox will fail in the near future. For piston models, small discrepancies are not so critical and quite fixable, because their design is repairable and, due to its simplicity, allows you to eliminate shortcomings.

The advantage of membrane products can be considered versatility, because they are designed to work in systems with a large pressure range. Therefore, they are used not only in apartments and houses, but also in industrial facilities, where the most important thing is the quality and reliability of water pressure regulation. Piston gearboxes are more practical to use due to their smaller dimensions and simpler design. If the scope of application does not imply high pressure and constant active work, then this option is preferable.

Also, a significant difference lies in the price, because the cost of diaphragm gearboxes is an order of magnitude higher due to their durability, longer resource and the possibility of operation in systems with high pressure.

Top manufacturers

In the niche of the plumbing equipment market, there are many well-known manufacturers, the products of each of which differ in their characteristics, scope, design and price. Among inexpensive gearboxes, one cannot fail to note models from Italian manufacturers: Valtec, Itap, ICMA. Their products can be safely attributed to quality products due to competent production control and emphasis on product simplicity. These companies have their offices in Russia, due to which gearboxes are easy to find in many plumbing equipment sales networks. The above companies are popular not only due to decent quality, but also due to a very diverse assortment, which includes both inexpensive and medium-cost models.

Another Italian manufacturer is Caleffi, known for the 533441 diaphragm reducer. It is equipped with all the advantages inherent in its type, namely: low noise level, absence of contamination in the working chamber, as well as a reliable design. It has a small size, protects the water supply system from both static and dynamic pressure. The central support is made of plastic, which does not adhere to scale. A robust diaphragm is used to reduce wear.

The body is made of chrome-plated brass, the pressure is adjusted from 1 to 6 bar by means of a screw located in the upper part of the gearbox. Diameter 1/2 ", maximum inlet pressure 16 bar. There are also minor drawbacks.The first of these is the absence of a pressure gauge, while in piston models it is mainly included in the package. There is also no scale for mechanical indication of regulated pressure.

It is impossible not to single out an American firm Watts, widely known all over the world and having many branches and representative offices. The gearboxes of this company are of high quality and reliability, which are the result of production technologies. The main part of the assortment is adapted to work in powerful plumbing systems, typical for production and industry of various sizes. When designing gearboxes, Watts focuses on a variety of product qualities: technology, structural design, optimal dimensions, and the ability to adjust and adapt products to suit the application.

Despite the company's bias towards industrial gearboxes, the lineup also has more familiar units intended for domestic use. Naturally, the cost of American membrane analogs is considerable, but it is fully paid off by the quality guaranteed by the manufacturer.

When listing the best manufacturers of any plumbing equipment, one cannot but mention the products of German companies. One of these is Herz with professional principles of work: stability and reliability combined with high quality. Diaphragm reducers of this company are distinguished by their configuration and simplicity, which are appreciated by consumers.... Installation and operation are also simplified. Among the many advantages, it is worth highlighting the relatively low price. There is only one drawback - Herz products are quite large, which can cause inconvenience in cases where space is limited.

What to consider when choosing?

It is important to pay attention to a lot of things before buying a diaphragm reducer. First you need to decide what size pipe is installed in your plumbing system. This is important for the subsequent installation of the product. As a rule, most pipes have a diameter of 1/2 or 3/4 ", but there are also such communications where dimensions reach 1" or even more.

It is advisable to study the structure of your water supply system in advance and proceed from the information already available. Otherwise, you simply will not be able to mount the gearbox and it will not bring you any benefit.

Then match the operating mode of the model you are looking for with how your system works.... If the movement of water in the network occurs constantly and in medium quantities, then it is better to purchase a product with a dynamic type of application. If the scope of application is purely household use, then you can make a choice in favor of static units. They are cheaper and their characteristics are enough for reliable and durable operation, provided that they are made of high-quality materials. They are no less important in the case of membrane analogs, since all subsequent operation depends on the quality of the TEPK.

Although household gearboxes are similar in their characteristics, one of them differs from model to model. It's about bandwidth. Here it is necessary to select a membrane depending on the load on the system. To do this, consider the number of people consuming water, as well as the availability of technology that uses resources.

Before buying, be sure to check for what temperatures the reducer is suitable. Not all units support operation with both cold and hot water.

If your system is simple enough in terms of characteristics, pipe size and other parameters, then with an extensive choice, make calculations for membranes with the largest number of display elements and other functions that will give more opportunities for adjusting the technique.

It is desirable that in the minimum configuration there was a pressure gauge with which it was possible to understand when to adjust the pressure.

The comment was sent successfully.