What are diffusion membranes and how to choose them?

Diffuse membranes are insulators used in the installation of building structures. In the article we will tell you what they are, what they are, what are the nuances of their choice and use.

What is it and what is it for?

The diffusion membrane is a building cloth used for solving various problems. It is used for roof waterproofing, preventing moisture and condensation from entering the insulation.

The membrane solves installation problems:

- a vapor barrier with an insufficient level of protection;

- vapor barrier material in violation of technology;

- structures made of wet lumber.

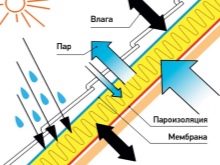

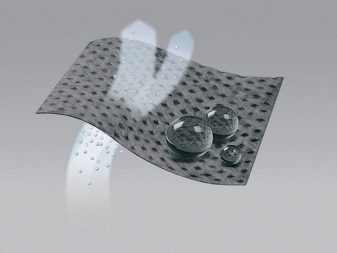

In addition, the material is used for other works. It appeared on the building materials market quite recently. It differs from traditional counterparts in the ability of one-sided moisture transmission. When used in conjunction with a heat insulator, the membrane does not allow water and air to pass through... In fact, this is a hydro-windproof membrane, an alternative to vapor barriers.

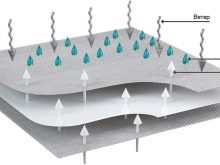

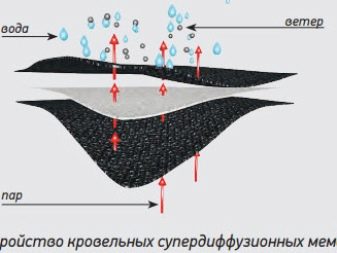

There are several layers in its structure, one of which is the main one. It consists of many tiny pores. Their size is so microscopic that they are able to pass water only in the form of vapor due to diffusion. It emerges from the living quarters of a wooden house into the street at the same atmospheric pressure on both sides of the membrane. The material removes steam from insulation formed by temperature extremes.

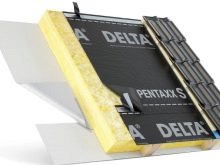

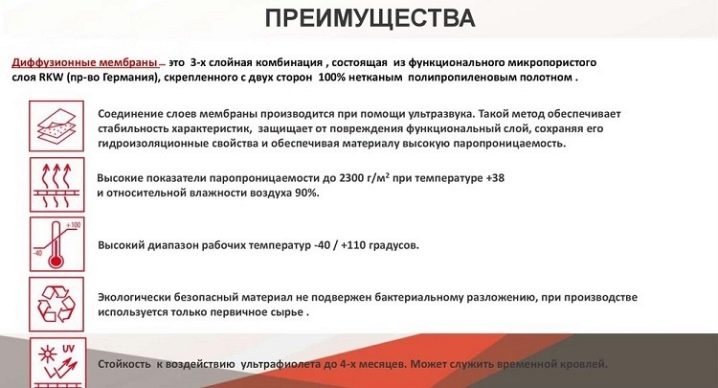

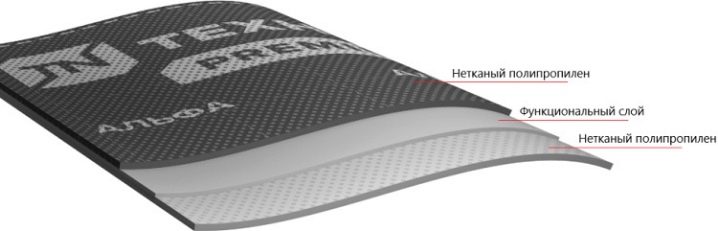

The material is supplied to the domestic market in rolls. The panels have a multilayer structure in the form of a capillary pump. The classical diffusion roofing membrane has a three-layer structure. Its upper and lower layers are made of non-woven fleece material (polypropylene). The inner layer is tensile resistant. The material protects the house from heat loss.

For ease of use, the sides have a different color. One of them usually has a picture or a trademark logo.

The areas of use are different. In addition to waterproofing pitched and seam roofs with under-roof ventilation, the material is used for thermal insulation of the rafter system in height, for laying wall and floor claddings. It is bought for ventilated hinged facades and load-bearing timber structures. This eliminates the need for additional impregnation of wood. It is bought to insulate a cold attic and for windows. In addition, a vapor-permeable construction membrane is used to create a roofing cake without insulation, when the cladding is slate, ondulin, polymer, ceramic, metal tiles.

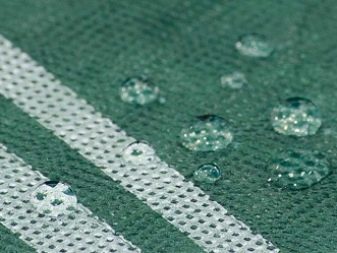

The material is reliable and durable, resistant to temperature extremes, acids and alkalis. It is safe for health and does not emit toxic substances at all times of use. It resists the intense influence of precipitation in gusts of wind. The membrane works by actively collecting moisture and transferring it to the perforated areas. Microscopic droplets seep out and escape.

Varieties

Most diffuse membranes are practically indistinguishable from each other visually. They are evaluated according to various characteristics, the key of which is the level of vapor permeability. It determines the ability of the canvas to pass water vapor. This parameter is referred to as the diffusion flux density. Based on this feature, they distinguish low, medium and high vapor permeable moisture insulators.

Variants of the first group are varieties with two or three layers and a reinforcing mesh. Such material does not have too great ability to remove water vapor. However, it can be used as a typical rain protection product. The analogs of the second group, called superdiffusion ones, have a much higher throughput. They protect the insulation layer from decomposition. Therefore, when arranging insulating layers, no ventilation gaps are left.

In addition, on sale there are volumetric membranes. It is they who are used in the insulation of folded, as well as metal facings. Roof separating insulators are mounted with an upper ventilation gap on titanium, aluminum, steel roofs. In addition to traditional membranes, modern construction uses specialized varieties of high-tech type... They combine the characteristics of a vapor barrier and insulation.

For example, these include an aluminum-sprayed metalized waterproofing membrane. It partially reflects heat while maintaining diffusion properties. For operation in hot regions, a foil-type membrane is produced.

Due to the foil, the material has the ability to reflect infrared heat outward into the atmosphere. Thus, the roof heats up less.

Specifications

The perforation density of the membranes is different. With its increase, the drainage capacity of the panels increases. Quality materials have a service life of about 50 years. The values of vapor permeability also differ. For low diffusion variants, it is less than 300 mg / m2. According to the manufacturers' recommendations, these are raw materials for dry rooms, internal partitions. Analogues of medium diffusion have a vapor transmission capacity in the range of 300-1000 mg / m2.

They are suitable for installation in medium to moderate climates. Superdiffusion modifications have a vapor permeability of more than 1000 mg / m2. Unlike other varieties, they can be used in regions with harsh climates and fluctuating humidity.

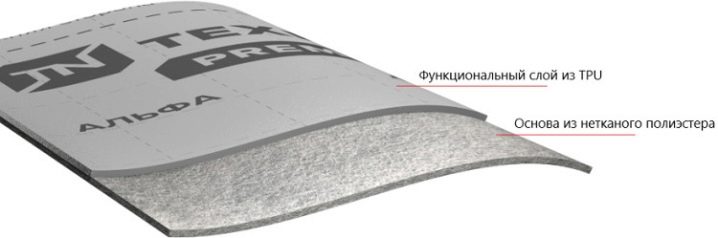

The higher this criterion, the thicker the type of insulation used in installation can be. The functional layer can be produced not only from polypropylene, but also from thermoplastic polyurethane. The outer layers protect the inner layer from mechanical damage. The inner part contains UV stabilizers.

Diffusion membranes do not lose performance when the temperature changes. They are not destroyed by the frost expansion of the ice. They do not lose their elasticity in winter, they can be mounted at any time of the year. Available on the market in a wide range of sizes... As a result, installation can be carried out with a minimum number of joints.

Top manufacturers

Domestic and foreign brands are engaged in the production of diffusion membranes. For example, a company supplies high-quality products to the domestic market. Technonikol... The manufacturer's vapor diffusion membrane is intended for waterproofing while protecting the structure from moisture. There are several varieties in the assortment, including versions with reinforcing fibers.

Among other products, Technonikol produces a superdiffusion polypropylene membrane with a double-sided type of application. It is used for roof structures with high requirements for insulation and strength.

The leading manufacturer in its segment is the trade mark Du Pont, which specializes in the production of protective membranes for wall and roof systems. The brand manufactures the Tyvek multifunctional polymer membrane. The material is environmentally friendly, suitable for use in decoration outside and for the internal structure of the cladding.

Products of the Izospan, Ondutis, Ecolife, Megaflex brands are in special demand and popularity.The products of the companies combine quality and reasonable cost.

Nuances of choice

The choice of a diffusion membrane depends on a number of factors. In addition to vapor permeability, you need to take into account the grammar, the indicator of water resistance. The mass of the membrane increases with its thickness. At the same time, the mechanical strength also increases. The grammage of the product varies in the range of 60-270 g / sq m. No less significant feature is the resistance to water pressure. The methods for determining the criterion are different. The easiest way to understand the markings is from W1 to W3. For example, modifications marked W1 can withstand a water pressure of 20 cm for 2 hours.

In order to select the right type of material, it is necessary to take into account the peak temperature effect. For standard samples, the values vary within 80-100 degrees. The materials have varying degrees of UV resistance. Basic options can be under the sun for up to 3 months. Reinforced - about 4. When buying, you need to take into account the angle of inclination, length, width of the roof slopes.

In addition to these parameters, the thickness of the ventilation gap, the type of insulation used in the arrangement of the roof are taken into account.

Installation of membranes

The installation of the membrane panel depends on the purpose. You need to choose the right side. Otherwise, it is impossible to avoid getting the heat-insulating material wet and disturbing the insulation work. The membranes are placed on the outside so that excess steam and moisture can flow through the ventilation gap in the lining. The material is mounted on the facade together with thermal insulation panels.

The construction with a supporting frame made of metal is made using volumetric membranes that create a wet drain without the appearance of rust. If the finish is lining or siding, the sheet is tightly fixed to the outside of the insulator under the decorative coating. The membrane should be laid on the side with the manufacturer's logo.

Bilateral

Double-sided varieties differ from traditional counterparts in the same appearance of the front and back sides. In this case, the question of choosing the right side does not arise. Installation of double-sided membranes significantly speeds up construction work. Laying involves stretching the canvas. In this case, the clean side of the material is placed to the insulation. It is important to isolate the places where moisture can enter the insulator through joints and loose fit. At the intersection of the penetrating elements, trapezoidal cuts are made.

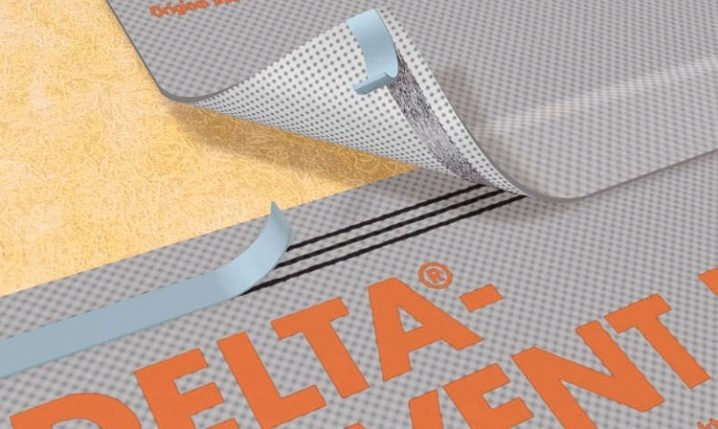

Installation begins with rolling and strengthening the rolls. They are rolled out parallel to the eaves, choosing the right outside side. Then secure with staples or nails. Mount the membrane with an overlap, having previously fixed it on the rafters in the overlap places (the overlap gap is 15 cm). After fixing the canvas, remove the protective film from the adhesive coating, iron the overlap. Then they are engaged in gluing with sealing tape. After that, the membrane is attached using glue or elastic bitumen-rubber tape. The final stages are the installation of the cornice on the bar and the sizing of the film.

Unilateral

Modifications of the one-sided type have different front and back sides. For example, with anti-condensation options, the side that should be directed inward is made on a fabric base. These membranes are not produced very often. Foil products also belong to them. When laying, it should also be located inside the room to be finished. Otherwise, there are no special differences in installation. In order not to doubt which side you need to lay this or that material, you must familiarize yourself with the instructions that are attached to the membrane. If the sides of the canvas are painted in a different color, you can navigate along them. As a rule, the outer side of the diffusion membrane is painted with a brighter color.

Not all one-sided modifications require hermetic gluing with self-adhesive tapes. Do not glue the joints with ordinary or narrow tape. From this, the joints will unstick rather quickly. The best type of membrane fastening is counter battens. If they are absent, it is better to use nails with wide heads. A construction stapler can also be used for fastening. The film can be mounted not only on insulation, but also on moisture-resistant plywood, OSB sheets.

The clearance of the anti-condensation membrane should be 4-6 cm on each side.

The comment was sent successfully.