Selection of superdiffusion membranes and their installation

Under-roof waterproofing is extremely important when it comes to construction in a wide variety of variations. The implementation of this process has its own technology, as well as materials and selection of tools. At the same time, one of the most popular products is superdiffusion membranes.

What is it and what is it for?

The answer to these primary questions provides information about the material and its application. Superdiffusion membranes are products that consist of several layers of polypropylene. The more of them, the stronger and more reliable the material. Accordingly, the price will also rise. In general, the standard options include two-layer and three-layer counterparts, as they allow you to have suitable characteristics without unnecessary waste.

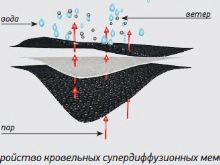

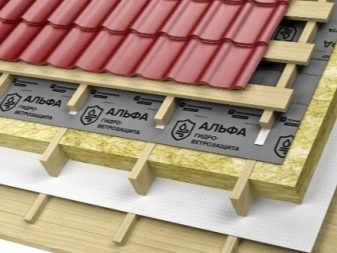

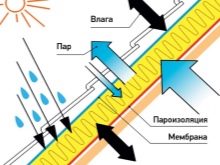

Superdiffusion membranes are located on the insulation and prevent it from getting wet. In addition, the product has the ability to let steam through, that is, to "breathe", due to which accidentally trapped moisture will not linger for a long time and will be released from under the roof structure in a short time.

The basis of the membrane construction is a non-woven canvas, which has many positive characteristics. When designing the so-called "roofing pie" and its correct arrangement, the builder will need to resort to the use of additional material, which can be attributed to the superdiffusion system. The membrane is designed to protect not only from water, but also from strong winds that can damage the under-roof space. A large number of positive qualities make it possible to operate this product in a variety of conditions.

The superdiffusion membrane finds its use in other building processes as well. These include wall cladding, the creation of a reliable base for floor logs, operation in houses for siding. Polypropylene material is used in a wide variety of variations - for facades, frame structures and other situations where universal protection of a building is needed.

Super Diffusion Membranes help reduce heat generation, which is extremely beneficial in cool weather.

Main characteristics

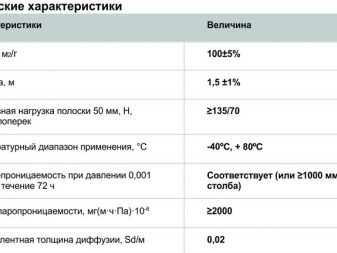

When choosing a membrane model and before purchasing it directly, it is necessary to pay attention to the characteristics that directly affect the operation and its reliability. First of all, this material has key parameters. One of these is density. It is important in that it reflects the characteristic of strength, which, in turn, makes it clear what physical damage the membrane can withstand.... The most common types of deformation are strains and punctures, which compromise the integrity of the structure.

As mentioned earlier, superdiffusion membranes can be composed of 2-4 layers of polypropylene. If the material is especially thick, then it will not be afraid of any damage. But it must be borne in mind that the installation of these models will become more difficult, and the flexibility will decrease. The selected density parameter should be correlated with the type of roof for which the product will be used. Tiles made of bitumen and metal are sufficient 110-125 g / m2, while for composite materials and natural tiles, it is better to choose a model with an indicator of 140-170 g / m2.

The second most important thing is to designate the vapor permeability parameter... Before buying, always pay attention to it, because it directly affects the entire operation of the membrane. A large number of factors affect the vapor permeability, but in any case, it is better to purchase a product with a higher rate. It depends on diffusion resistance, 0.1 meter of which corresponds to 10 cm of air in the form of a layer under the waterproofing. Good vapor permeability will allow accidentally trapped moisture to leave the roof as quickly as possible, so that it will not entail negative consequences in the form of dampness. Another important characteristic is elongation at break. This indicator is measured in percentage and makes it clear how much the material can deform without fatal changes in its design.

Naturally, during installation, builders do not assume that the membrane will undergo ruptures and other deformations, but this takes place after long-term operation. Accordingly, the more elongation, the better. Do not forget about the breaking load, which is a consequence of the density. This indicator is distributed depending on the deformation vector - along the width and length. It is also indicated as a percentage. It is these characteristics that reflect the main vapor barrier and wind and moisture protection properties of superdiffusion membranes.

Naturally, each manufacturer, at its discretion, sets the overall dimensions, which are worth paying attention to. This is especially true for situations when you need to mount the product on walls and floors.

Comparison with other materials

It is very interesting to consider superdiffusion membranes not only as a material in itself, but also to compare it with their counterparts on the construction raw materials market, because consumers are exploring a variety of options before buying. It is worth starting with roll options, which are represented by roofing material and other materials from bitumen and polymer resins... They have long been used as a basis for waterproofing, and therefore a considerable number of people know about them.

Roll materials are technologically outdated in comparison with membranes, they do not have a proper wind and moisture protection structure. Despite the most different models, they all have inadequate characteristics.

Among the minuses, it is worth noting low vapor permeability, as well as flammability and the need for difficult installation, which consists in additional surface preparation during installation. The only advantage of roll products is their low cost. But at the moment, such materials should not be considered as a competitor to the membrane, because their difference in manufacturability is extremely large.

A more serious competitor can be called mastic. For a number of certain indicators, for example, durability and thermal insulation properties, it is comparable to a membrane. But for the installation of mastic, a considerable number of conditions must be observed. So, you can only apply it on a flat surface that must be prepared in advance. And also the mastic does not have proper vapor permeability and must be flat in all installation areas.

This can be done, but it will take a lot of effort and time. Of course, mastic is inexpensive, but inferior to the membrane and its simple method of application. Powder coatings are also used for waterproofing. After mixing them with a solvent, they perfectly take up space at seams and joints, as well as in cracks.

But powder analogs are not elastic and not as reliable as membranes. Most of these materials are used for interior decoration, where there is no shrinkage and vibration. Water-based materials are very popular, among the advantages of which are easy application, excellent water-repellent properties, and good vapor permeability. But do not forget that liquid analogs are unhealthy and susceptible to washout, which is why you will need to apply them at regular intervals.

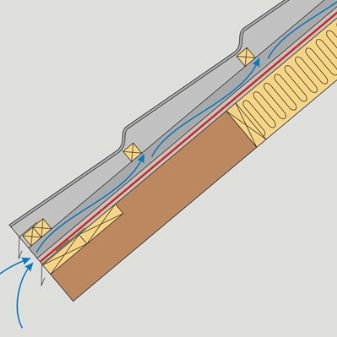

And this, in turn, will lead to high costs. Superdiffusion membranes are superior to other film products that require a ventilation gap. This complicates installation and requires a certain amount of space.

In the absence of a gap, the pores of the film will clog, and the diffusion properties will decrease their effectiveness over time.

Top manufacturers

Among the many variations, consumers are trying to find the optimal product in terms of price and quality. The top manufacturers of such membranes include a number of companies, so there is an opportunity to choose for your building configuration and scope of application. The most famous brand is the diffusion membrane MASTERMAXproduced in Hungary, Poland and several other European countries. Among the main advantages, it is worth noting a wide variety of assortment, which includes various models. They differ both in technical characteristics and in areas of application.

For example, a product CLASSIC has a three-layer structure with basic characteristics. Due to its good characteristics, this material is used as a secondary protection against dust and moisture. The cost is very low, installation and operation are simple. Model TOP made in a more technologically advanced version, as it is adapted for operation in places with high humidity and strong wind. EXTRA equipped with more serious strength characteristics, and therefore can be used in extreme conditions. The main focus is on elongation and breaking load. The cost is higher than that of the rest of the range, but the quality is also superior to its counterparts.

Another popular membrane brand is Difoil-S... It is based on three layers of polypropylene. The manufacturer has made an emphasis on the fact that this model has excellent parameters of vapor permeability and thermal insulation. Water vapor is removed from the room extremely quickly, thereby preventing the roof from rotting. Difoil-S is most often used for the installation of roofs of buildings with an attic or with a complicated construction system. Installed directly on the insulation without the requirement for circulation. It is used for wind and moisture protection of walls with a heat-insulating layer.

The density is 90 g / m2, the vapor permeability is 0.05 m, and the water resistance is class W1. This membrane is resistant to temperatures from -24 to +70 degrees, which allows it to be used in many regions. And also you should pay attention to the company's products. TECHNONICOLwhich sells superdiffusion products PLANTER and a standard reinforced model. Each of them has good physical characteristics, and easy installation allows you to use it in different fields of activity. The density is 150 g / m2, elongation at break is 60%, vapor permeability is 1000 g / m2 per day. Among other indicators, 4 months of resistance to ultraviolet radiation can be noted.

Selection Tips

Before choosing a membrane, one should proceed from its design and technical characteristics. If everything is clear enough with the latter, then the inner part of the product needs to be studied. During acquisition, try to rub the material with your fingers and examine it in layers. The most recommended option is the presence of three layers, because in this case the structure will be dense, and the installation will remain simple due to the elasticity index.

And also find out in advance what specialization the membrane has. Some manufacturers create models for specific needs, and they are not always suitable for other applications.

Before making the final choice, it is advisable to study the documentation with all the useful data about the product.

Installation nuances

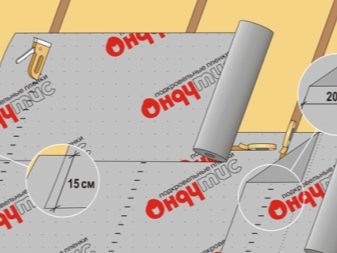

The superdiffusion membrane installation scheme is not complicated and feasible even for amateurs.As for the direction of laying the film, it is carried out parallel or perpendicular to the overhang. Variations in direction do not give any definite advantages. In this case, it is important to position the membrane with the perforated side outward so that it can release steam and not allow water to pass through. The installation should have an overlap of about 20 cm between the foil strips.

Fastening is carried out with roof brackets, and in such a way that the final overlap places are on wooden structures. At the same time, the membrane is nailed under the roof.

The comment was sent successfully.