What are bayonet shovels and how to choose the best one?

Most people who have their own, even a small piece of land, know well what a bayonet shovel is. This tool has been indispensable for a long time. With its help, you can not only loosen the ground and plant plants, but also dig a hole or ditch, load the soil onto a cart. In order for the tool to be convenient and reliable, you need to choose it correctly. Knowledge of its characteristics, storage and operation rules will help in this.

What is and what does it consist of?

A bayonet shovel is a mechanical tool. The tool is designed for construction work and soil cultivation. It got its name from its pointed flat shape, which resembles a bayonet. Its surface is slightly concave, and the upper edge forms a perpendicular with a handle (handle). Such a device makes the pressure with the foot easier, which simplifies the workflow. The instrument has several varieties, but the structure is the same for all types. A bayonet shovel consists of:

- from canvas (bayonet);

- tuleikas;

- cutting.

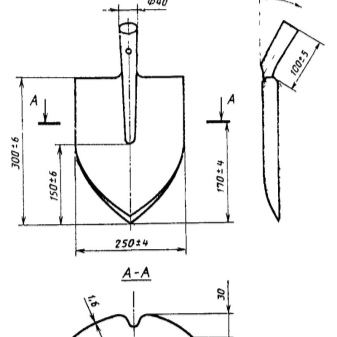

The canvas is the main working part of this structure. They directly affect the soil. It is equipped with curved edges at the top of the bayonet, which are called offensive. Its rectangular shape is considered to be the most suitable for increasing the pressure on the blade during operation. The right angle of advance is an important feature of the bayonet shovel. If it is changed upwards, then the efforts made will become less effective. And if in the process of work the edges of the offensive bent and began to form a smaller angle, then an additional load on the leg will be created, which leads to injuries and various pains in the leg.

The next part, called the tulle, is designed to securely attach the bayonet and handle. It can be either a separate part or a monolithic structure with a canvas. In the first case, it is fixed independently by welding or bolts, and in the second, the fastening is carried out by the manufacturer.

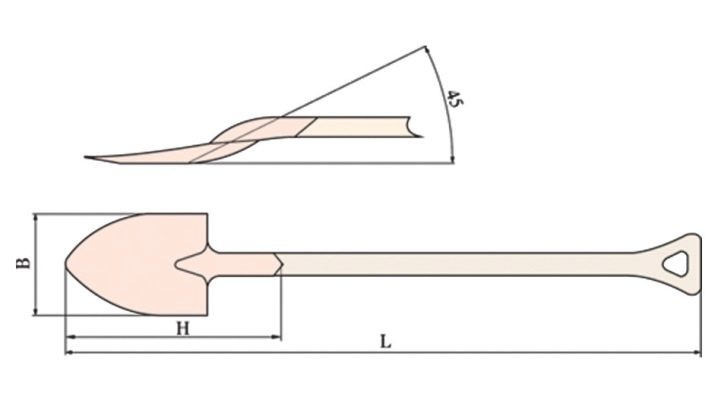

The handle is the handle of the shovel, which has an oblong shape. It is securely fixed in the tunic, after which the instrument is considered assembled and ready for use. Most often, wooden handles are produced, since this material is easy to process and has a low weight (with appropriate drying). However, nowadays you can find cuttings made of plastic or metal. Polymer handles are fragile and unreliable, and metal - most often homemade variations - are too heavy.

The presence of a handle in the design of this tool greatly facilitates the workflow, since it is an additional power lever that reduces labor costs when digging out heavy soil. In some modifications the handle is equipped with an additional pommel handle. This design makes it easier to carry and load.

Specifications

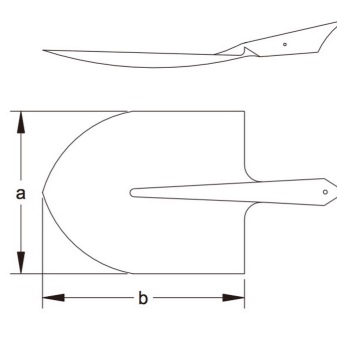

The size of the blade of a bayonet shovel, as well as its weight, depend not only on the material, but also on the area of operation of this tool. The standard dimensions of the shovels are established by GOST. Some metallurgical plants still use Soviet documentation, according to which the width of the product should be 20 cm, the length - 27 cm, and the tulle - 9 cm.However, modern manufacturers have significantly expanded the limits of permissible values.Today, the following are considered normal working dimensions: width - from 18 to 21 cm, length - from 33.5 cm to 40.5 cm.

The sizes of the handle also vary in a significant range: from 110 cm to 150 cm. At the time of purchase, you need to focus on this parameter, since the wrong choice of the size of the handle can lead to stretching of the back muscles and, as a result, to painful sensations. Therefore, the stalk must be chosen individually, taking into account the growth and convenience when making digging movements.

Views

Bayonet shovels are distinguished on several grounds: according to the material from which the tool is made, according to the shape of the bayonet, and according to its purpose. The material of the blade is the most important criterion when purchasing this tool. Currently, manufacturers use several options for raw materials:

- titanium;

- stainless steel;

- spring steel;

- rail steel;

- ordinary steel.

A material such as titanium has come to be used in the manufacture of shovels relatively recently. It is in high demand among farmers due to its lightness and strength. But the complete lack of flexibility of such a bayonet is a disadvantage. With significant effort during operation, the blade can easily break. In addition, the high cost also does not favor this material. Stainless steel is considered the next material in demand. Although it surpasses only ordinary metal in strength, it is wear-resistant and durable. In addition, it has average fragility and a fairly low price.

Steel is the most common raw material for bayonet shovels. This alloy copes well with earthwork when the soil is soft and free of stony inclusions. And its cost is much lower than that of other types of material. Therefore, ordinary summer residents prefer to buy this particular option. But the tool also has disadvantages. This is an increased sensitivity to corrosion, and high brittleness, and a fairly large weight.

High-alloy spring steel can be said to be much stronger than conventional steel and, in addition, has sufficient flexibility. This allows the tool to be used for a long time. In terms of weight, this material is inferior to titanium and steel alloys, but only slightly: only 8 percent. The cost of the material is slightly lower than that of titanium. There is another material that stands out for its high strength - this is rail steel. For the manufacture of shovels, defective rails are most often used. High strength characteristics in this case are explained by double hardening. After it, the alloy becomes high-carbon. But this material is also quite elastic. Therefore, the tool made of rails is suitable for working in dense soils. He is able to carry heavy loads.

Depending on the configuration of the bayonet and the length of the shank, the shovels are divided:

- on bayonet;

- garden;

- sappers;

- semisovkovy;

- shovels.

Bayonet shovels have universal shapes that are suitable for work not only in the garden or vegetable garden, but also in construction, as well as during loading operations. Their construction can sometimes be reinforced with small stiffening ribs, located symmetrically, on both sides of the working blade. A garden shovel has a narrower application - digging up soil in a personal plot. It has an almost rectangular shape and an additional pommel handle across the handle. This creates additional emphasis and facilitates the work process. A variety of such a highly specialized tool is a drainage shovel. It has a narrow, elongated, slightly curved blade, which is excellent for widening holes and clearing ditches.

The sapper blade is intended for use by the military, therefore it has sufficient bayonet strength and a small handle. The weight and dimensions of such a tool are small, for which it received recognition not only among different types of troops, but also among motorists.Such a lightweight version easily fits into the trunk and helps out in case of erosion of dirt roads. Half-shovels are a kind of hybrid of a bayonet and a shovel. And the capabilities of this species are also advanced. The spoon-like bayonet shape and its inclined position in relation to the handle make the tool suitable for digging and loading work. A great example of this type is the fire shovel.

The shovels live up to their name and are mainly used for loading and unloading various materials, both organic and artificial. Modern bayonet shovels have another feature - the telescopic handle. If necessary, it can be unfolded or folded. Adjusting the length of the handle makes the tool versatile.

Model rating

There are many manufacturers of bayonet shovels on the market today. Most of the brands are represented by Russian manufacturers. Of the foreign firms producing classic bayonet products, one can single out the company Gardena... Its products are distinguished by their high German quality and well thought-out equipment. The company mainly produces garden tools. Their shovels are made of stainless steel, however, due to the light aluminum handle, the weight of the product is low. The only drawback of these shovels is the price, which is 3 times higher than the average cost of domestic counterparts. The company gives a guarantee for its products for 25 years. Therefore, this brand is considered the best.

Black & decker Is another foreign company for the production of garden tools, however, it cannot boast of such reliability. And at the same time, the prices for its products are quite high.

From Russian manufacturers, several worthy options can be distinguished at once. First of all, it is firm "Zubr", which produces a wide range of goods of this type, including for garden and construction work. Models "Master" and "Favorite" are prominent representatives of the lineup. They are equipped with a D-shaped handle, which is comfortable to use. The handle is made of high-strength wood - ash. You can dig any soil with a shovel. The steel bayonet is powder coated to protect the metal from corrosion. The tool has an average weight of 1.8 kg.

LKO products are in approximately the same quality range. But it is worth noting a slightly more practical weight of the product, which is about 1.5 kg.

Fiskars Solid uses boron steel for the manufacture of shovels. This indicates the strength of the material, but leaves little doubt about the possible occurrence of corrosion. The weight of such products is also about one and a half kilograms. The disadvantages include a metal handle, which can create difficulties when working in subzero temperatures. The manufacturer suggests using a plastic handle, but it is not always convenient to use it. However, the low cost of the products of this brand captivates.

The next domestic manufacturer is Finland - manufactures stainless steel bayonet shovels, equipping products with ergonomic handles. This allows you to slightly reduce the weight of the tool, but the price is twice as high as that of the previous company.

It should be noted that there are also American shovels on the market. They are produced by firm "Dachnik"... The stainless steel tool has a handle made of high quality and durable eucalyptus wood. This helps protect the grip from insects. Garden tools from this company are distinguished by the presence of a Teflon coating, which is easier to clean from the ground. The handle is equipped with a foam rubber ring to protect hands from chafing. But this attribute wears out quickly, which is a significant drawback, since it is necessary to look for the same nozzle. And these are additional costs.

How to choose?

The main criterion for choosing a shovel is its size.A good shovel has an average bayonet size. They can vary from 18 to 35 cm. At the same time, for the convenience of work, the size of a titanium shovel with a wooden bayonet can be slightly larger than the width of a shovel made of rail steel with the same handle, since titanium weighs less. In a bayonet shovel, important parameters include the width of the offensive, which for maximum comfort and efficiency should be in the range from 1.4 to 1.8 cm.

The length of the shaft of the bayonet shovel should not be too long or too short. For a standard shovel, this parameter is 90–100 cm. More precisely, you can determine the data during the selection process. It is enough to put the product on a flat surface and try it on to the shoulder. The handle should not be more than 10 cm higher than the shoulder level. After determining the dimensions, you can proceed to more general indicators. So, the shovel's sleeve should be open at the end. If the hole is sealed, the stalk will rot over time due to the constant stagnation of water at the end of the product. The wooden shank at the bottom of the shovel needs constant ventilation.

Subtleties of operation and maintenance

In order for the instrument to serve as long as possible, it is necessary to handle it correctly. This implies periodic sharpening, which reduces the stress on the blade, cleaning and proper storage. You can sharpen the end of the shovel with a special machine or grindstone. The sharper the edge of the shovel, the better. Also, after the end of the work, the canvas and the shaft are cleared of the ground as much as possible. Then they are placed for drying and further storage in a dry ventilated area. In this case, the tool with a sealed tulle must be placed with a bayonet upward for water drainage and better drying.

It is also important to monitor the tightness of the connection between the handle and the bayonet of the shovel. Loosening this knot can cause the handle to break at the most inopportune moment. Therefore, you need to check the connection before starting work in order to fix it in time if necessary.

For a long service life of the wooden handle itself, it must be periodically painted, for example, with a stain. This will protect the wood not only from moisture, but also from insects. Seasonal treatment of the instrument with preservative compounds is also important. When preparing for winter, you need to carefully coat the bayonet of the shovel with machine oil or kerosene to prevent metal corrosion. The exception is stainless steel, which is not afraid of moisture.

For information on how to choose a bayonet shovel, see the next video.

The comment was sent successfully.