Wooden shovels: pros, cons and recommendations for choosing

In winter, any owner of a private house is faced with the task of cleaning the area adjacent to the house. Snow, which often forms huge drifts, can become an obstacle not only for a car to leave the garage, but also so that household members can simply leave the house. The simplest solution to this problem is to purchase a wooden snow shovel.

Advantages and disadvantages

A wooden shovel is a budget option for a manual snow blower. In a store or market, this tool may be called a plywood shovel. You can make it yourself at home. Despite the fact that its main advantage is its relatively inexpensive cost, it is short-lived. Hence the following drawback of this model follows. It is permissible to use a plywood shovel only for clearing the area from freshly fallen snow.

Removing ice or wet layers of snow from the surface will be extremely difficult. Due to the fact that the surface of plywood is made of wood, when it gets wet due to working with snow, it increases in weight and makes the cleaning process extremely laborious.

In addition, constant moisture provokes splitting in the plywood structure, and the manual snowplow is unusable.

However, manufacturers have found this solution by equipping wooden models with special metal edges, which allow to extend the operational life of the shovel. But since the moisture-resistant characteristics of plywood are low, the shovel will sooner or later begin to crack.

Therefore, owners of wooden models are strongly advised to dry them after every snow removal.

Selection recommendations

In order not to be disappointed after purchasing a snow shovel, it is recommended that you familiarize yourself with some important criteria for choosing this tool. With the help of them, the owner will not only be able to choose an option that will cope with the task at hand and will meet his requirements, but will also save a significant amount. Since, having chosen a high-quality shovel, she will not have to look for a replacement after some time.

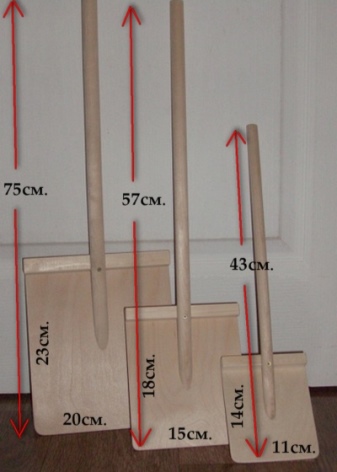

- The dimensions of the chute are an important characteristic when choosing a shovel. First of all, you need to take into account your physical capabilities. Having given preference to a shovel with a wide tray, which, although it will allow you to collect a fairly large amount of snow, will still exert a very serious load on the owner's back and shoulder joints. However, this disadvantage can be solved thanks to the small wheels. This type of shovel can be purchased ready-made or made yourself. It should be noted that the standard tray size is 40 centimeters.

- The slope angle affects the comfort when working with a wooden shovel. The tilt of the implement base can be used as a lever. This will greatly facilitate and speed up snow removal. The best option is a shovel with an angle of inclination not exceeding 20-25 degrees.

- The length and weight of the cutting will affect how quickly the owner gets tired of cleaning the snow. The fact is that the comfort of this process ensures that there is no need for a person to constantly bend over and unbend. Therefore, it is recommended to give preference to a long and light cuttings.When buying, it is advisable to carry out several strokes with a shovel in order to get an idea of which product you will have to work with.

- The sides are an equally important criterion for a snow shovel. Their presence will allow you to keep a large amount of snow when clearing it. Thus, maximum precipitation will remain on the surface of the tray, and the process will take less time. It is advisable to give preference to wooden shovels with deep sides.

How to make it yourself?

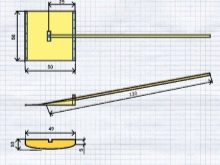

As mentioned earlier, plywood is not the most durable material, so a shovel made of this material will have to be replaced next season. However, nothing prevents the owner of a private territory from making this weapon on his own, moreover, the materials involved are of low cost. First you need a plywood sheet that has a good density. Next, you need to cut out a square, the side of which will be 50 centimeters. The tray can be resized to suit your preference. Further, it is recommended to subject the future cutting to a synthetic resin (epoxy) treatment, which will increase the moisture-resistant characteristics of the plywood sheet. If desired, you can make and attach a metal border on the sides of the tray.

Such a snow shovel will last much longer.

A ready-made stalk is available at any hardware store. It is inexpensive. In order to attach it to a plywood tray, you will need to file one of the edges at an angle of 45 degrees. To accomplish this task, an electrically jigsaw will help. The resulting cut is sanded with sandpaper and processed with any paint and varnish product. This will help protect the cutting from corrosion damage. For the stability of a wooden shovel, it is necessary to mount the handle in two areas at the same time. For the first, you need to drill a 6 mm hole and insert a bolt and 2 nuts, tightening them well.

For the second hole, you will need to select a location at the point of contact between the cutting and the tray. Drill, place the bolt and tighten with nuts. The final stage in the independent manufacture of a wooden shovel from ordinary plywood is its processing with paints and varnishes and impregnations. Most people ignore the final stage, which is extremely wrong. It is extremely important to take care of protecting the material from the possible appearance of cracks, as well as from the destructive effects of fungi and various harmful microorganisms. If the plywood tray cracks or breaks completely, you can always replace it, leaving the handle.

How to make a shovel for clearing snow with your own hands, see the video below.

The comment was sent successfully.