Polycarbonate fence construction technology

Fences could always hide and protect a home, but, as it turned out, blank walls are gradually becoming a thing of the past. A new trend for those who have nothing to hide is a translucent polycarbonate sheet fence. It looks quite unusual, and in combination with artistic forging - impressive and representative. Before demolishing a solid stone fence, you need to understand what carbonates are and what are the features of working with them.

Peculiarities

Polycarbonate is a transparent heat-resistant substance belonging to the group of thermoplastics. Due to its physical and mechanical properties, it is widely used in various fields of production. Most methods of polymer processing are applicable to it: blow molding or injection molding, creation of chemical fibers. The most popular is the extrusion method, which allows you to give a granular substance a sheet shape.

As such, polycarbonate quickly conquered the construction market as a versatile material that can even replace classic glass.

Such high marks are explained by the following characteristics:

- Withstands significant mechanical loads, is durable, retains the shape specified during processing. At the same time, prolonged abrasive action adversely affects the appearance of the material, leaving unaesthetic scratches;

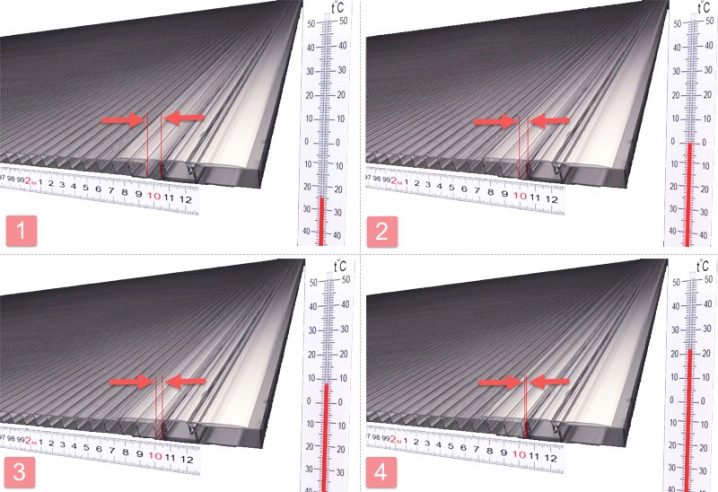

- Resistant to temperature changes. On average, the temperature range of most brands is from -40 to +130 degrees. There are samples that retain their properties at extreme temperatures (from -100 to +150 degrees). This property makes it possible to successfully use the material for the construction of outdoor objects. During installation, it should be borne in mind that when the temperature changes, the linear dimensions of the sheets also change. Thermal expansion is considered optimal if it does not exceed 3 mm per meter;

- Possesses chemical resistance to acids of low concentration and solutions of their salts, to most alcohols. Ammonia, alkali, methyl and diethyl alcohols are best kept away. Also, contact with concrete and cement mixtures is not recommended;

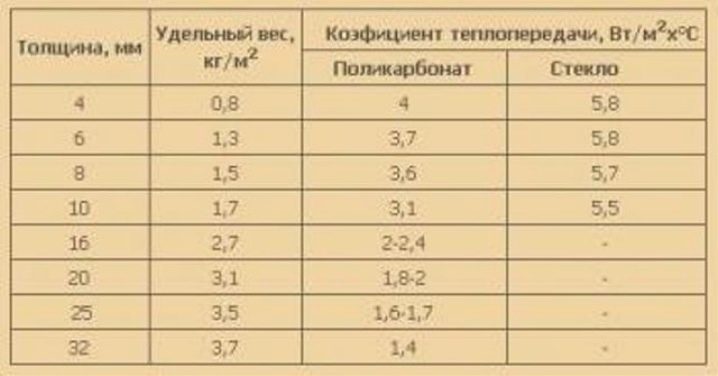

- Wide range of panels in thickness. Most often, in the markets of the CIS countries you can find indicators from 0.2 to 1.6 cm, in the EU countries the thickness reaches 3.2 cm. The specific gravity, as well as heat and sound insulation, will depend on the thickness of the material;

- Thermal insulating properties of polycarbonate are not decisive, however, in terms of heat transfer, it is more efficient than glass;

- High performance of sound insulation;

- Environmentally friendly due to its chemical inertness. It is non-toxic even under the influence of high temperatures, which allows it to be used without restrictions in residential premises;

- Has a fire safety class B1. Hardly flammable - ignition is possible only with direct exposure to fire and when a certain temperature limit is exceeded. When the source of fire disappears, combustion stops;

- Long service life (up to 10 years) is guaranteed by the manufacturer, subject to correct installation and operation;

- Optical characteristics. Light transmittance depends on the type of polycarbonate: solid is capable of transmitting up to 95% of light, for a cellular material this indicator is lower, but it perfectly diffuses light;

- Water permeability is minimal.

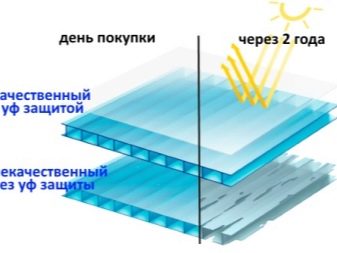

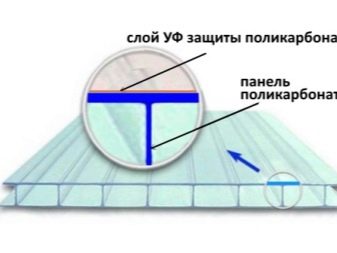

Judging by its properties, polycarbonate is a really wonderful material, but not everything is so simple.In its pure form, under the influence of ultraviolet radiation, it loses its optical (transparency) and mechanical (strength) qualities. This problem is solved by using UV stabilizers, which are applied to the sheets by coextrusion. The base and backing layer are firmly fused to prevent delamination. Usually, the stabilizer is applied only to one side, but there are brands with two-sided protection. The latter will just be the best option for protective structures.

Views

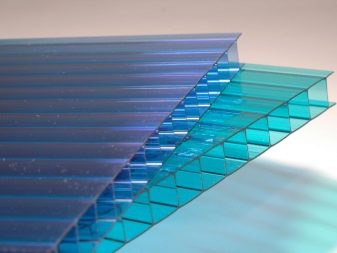

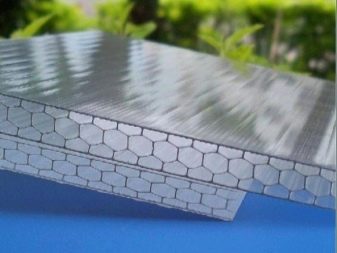

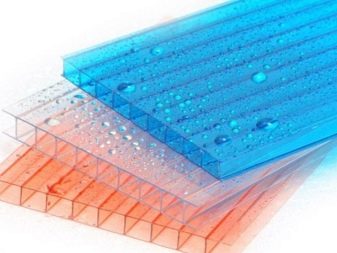

According to the internal structure, the sheets are of two types: honeycomb and monolithic. The third group of textured polycarbonates can be provisionally distinguished.

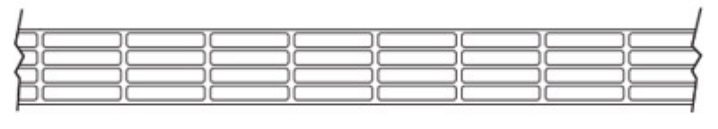

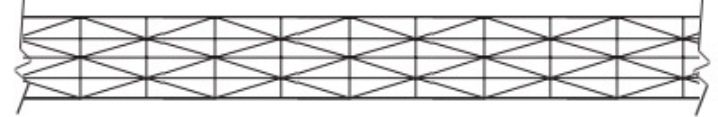

- Honeycomb or honeycomb panels consist of numerous chambers formed by internal stiffeners. If we look at the sheet in cross section, then the similarity with honeycombs in 3D becomes obvious. Air-filled sections enhance the material's insulating properties and strength characteristics. They are available in several versions:

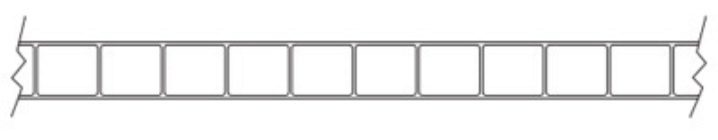

- 2H have rectangular cells, they are found in samples up to 10 mm thick.

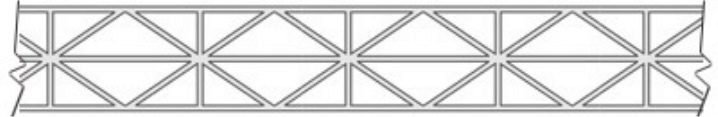

- 3X They are distinguished by a three-layer structure with rectangular and inclined partitions.

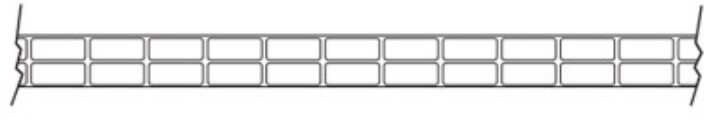

- 3H - three-layer with rectangular cells.

- 5W - five-layer sheets with a thickness of 16 to 20 mm with rectangular sections.

- 5X - five-layer sheets with straight and inclined stiffeners.

- Monolithic panels have a solid structure in cross section. They are very similar in appearance to silicate glass. It is monolithic polycarbonate that is often used in the creation of modern double-glazed windows.

- Textured panels have a textured surface obtained by embossing. This most decorative type of polycarbonate sheets is characterized by high light transmittance and diffusion characteristics.

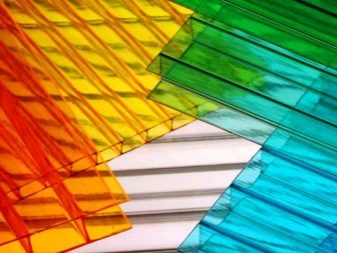

Decor

Another quality for which polycarbonate is valued is a wide selection of colors for both honeycomb and monolithic sheets. Coloring is carried out at the initial stages of panel production, so the color saturation does not decrease over time. On sale you can find transparent, opaque and translucent materials in all colors of the rainbow. The variety of colors, coupled with the physical and mechanical properties of the material, make it very popular in the design environment.

Constructions

In the construction of protective structures, honeycomb-type panels with a thickness of at least 10 mm are most often used. There are various designs: modular and solid, on a wooden, stone or metal frame, but combined fences look the most organically. In them, polycarbonate acts as a decorative element, guaranteeing sound insulation, flexibility, heat resistance and a wide variety of colors. At the same time, the reliability of the fence does not suffer: the polymer is able to withstand significant loads, but it is still not comparable with metal or stone.

Despite the variety of options, most often there is a fence on a metal frame... This popularity is due to the ease of installation and budget. The whole structure consists of support pillars, to which transverse joists are attached. The finished frame from the inside is sheathed with polycarbonate panels. The strength of such a structure is controversial: the metal crate is usually made with a large step, and the panels are easily damaged by a direct blow. This option is perfect as a decorative fence, for example, as a border between neighbors.

Mounting

The sequence of installation of a polycarbonate fence is not much different from the installation of fences made of other materials. The stages of the construction of the simplest structure should be considered in detail.

The preparatory stage includes:

- Study of the soil. The type of foundation depends on its stability: columnar, tape or combined.

- Design.The dimensions and design of the future structure are determined, a drawing is drawn on which the distance between the supports (no more than 3 m), the number of lags and the location of additional elements (gates, gates) are noted.

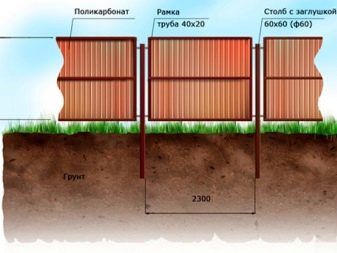

- Selection of materials and tools. For the supporting pillars, profile pipes of 60x60 mm are chosen, for the lathing - pipes 20x40 mm.

When everything is ready, you can start marking the territory. It is convenient to use rope and pegs for this. The latter are driven into the places where the supports are installed. Then comes the turn of the foundation. The columnar base is chosen for structures made of lightweight materials. The easiest way to prepare it. For this, wells are drilled 20 cm deeper than the level of soil freezing (1.1-1.5 m for the middle lane). The supporting pipes are inserted strictly vertically into the holes, and poured with concrete.

For areas with difficult terrain or unstable soil, you will have to resort to a strip foundation. According to the markings, they dig a trench with a depth of half a meter, at the bottom of which a drainage layer of sand and gravel is installed. If you plan to raise the foundation above ground level, then additionally install a wooden formwork. Further, supports and fittings are mounted on the drainage cushion, and the entire structure is poured with concrete. Setting time is about a week.

Installation of the frame consists in installing horizontal lags in several rows (depending on the height). Two options are possible here: tightening the elements with ordinary bolts or welding. After that, a plug is installed on the pillars from above to prevent the ingress of water and debris, and the entire frame is primed and painted. Before painting, it is advisable to drill holes in the polymer attachment points. The most important thing is the polycarbonate mount.

Successful completion of work ensures that several rules are followed:

- sheathing should be started after all manipulations with the frame;

- the optimum temperature for installing the polymer is from 10 to 25 degrees. Earlier, it was mentioned about the properties of the material to contract and expand depending on the temperature. In the range of 10-25 degrees, the leaf is in its normal state;

- the protective film is kept until the end of the work;

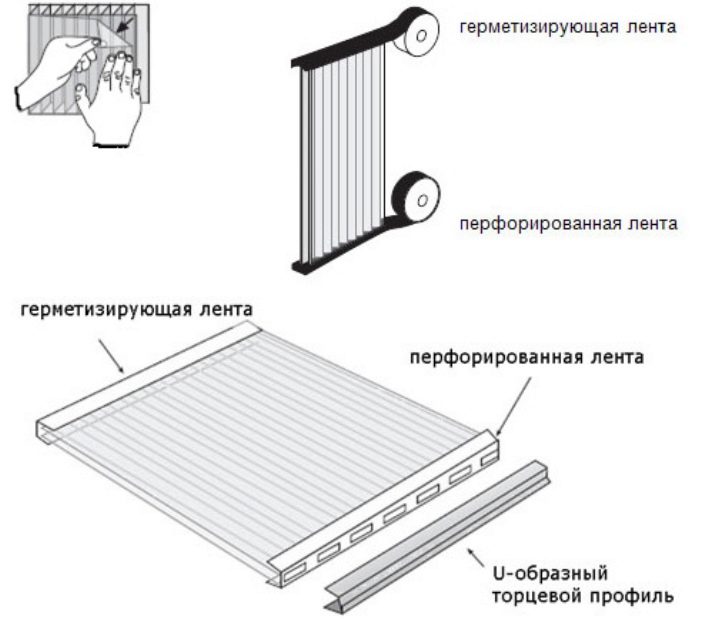

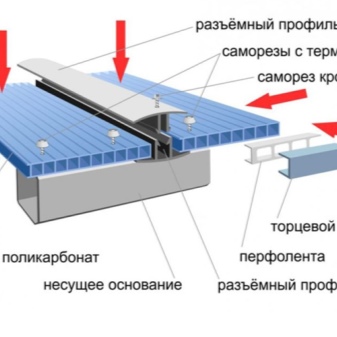

- sheets of cellular polycarbonate are positioned so that the stiffeners are strictly vertical. This will ensure the smooth drainage of condensation and moisture;

- cutting sheets up to 10 mm is carried out with a sharp knife or fine-toothed saw. Thicker panels are cut using a jigsaw, circular saws. It is important to cut in such a way that when installed between the polymer web and other elements, there are gaps of a few millimeters for expansion;

- in order to protect against debris and moisture, the ends of the cut sheets are pasted over with a sealing tape on the upper side, and at the bottom - perforated (for condensate release). Polycarbonate end profiles are installed on top of the tape. Drainage holes are drilled along the lower profile at a distance of 30 cm;

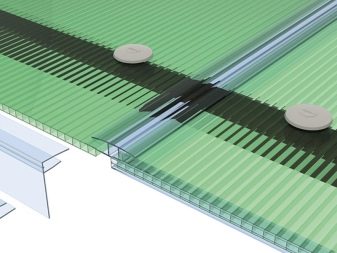

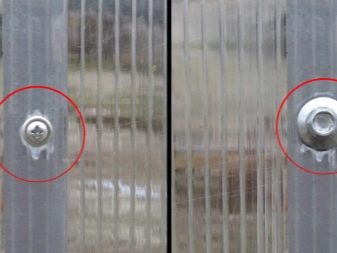

- polycarbonate sheets are fixed on the crate with self-tapping screws, therefore, holes are drilled in them in places of future fastening with a step of 30-40 cm. They should be located at the same level and correspond to the holes made earlier on the logs. The minimum distance from the edges of the panel is 4 cm. For the honeycomb material it is important that the drilling is carried out between the stiffeners. To compensate for the expansion, the size of the holes should be 2-3 mm larger than the diameter of the self-tapping screw;

- fastening is carried out with self-tapping screws with rubber washers. It is important to avoid excessive contraction as this will deform the sheet. Angled bolts will also damage the material;

- if a fence of a solid structure is planned, then individual sheets of polymer are connected using a special profile;

- when all work is completed, you can remove the protective film.

Reviews

The opinion of the people regarding the polycarbonate fence is ambiguous. The main plus, according to members of the forum, is the weightlessness and aesthetics of the fence.At the same time, users question the reliability and durability of such structures. For a more durable structure, they advise choosing sheets with a large thickness and with double-sided UV protection. True, the cost of such panels exceeds the price of flip-lists.

The slightest mistake in installation reduces the service life of the material to a couple of years. Such an unusual material attracts the attention of vandals: everyone strives to test it for strength. Honeycomb panels with plugs at the ends fog up from the inside, and without plugs, although they are ventilated, they collect dirt and debris. Many do not consider the transparency of the material a plus. Most agree that this expensive material is only suitable for decorative fences or as a decoration on the main fence.

Successful examples and options

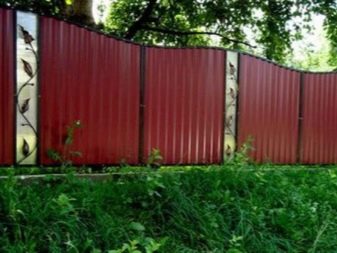

Among the successful projects made of polycarbonate, you can include a fence made of forged gratings, sheathed with polycarbonate sheets. This stylish solution for a private house combines the strength of metal and the illusion of fragile glass. The combination of forging, brick or natural stone and honeycomb or textured polymer looks good. Even the industrial look of the corrugated board is enlivened by polycarbonate inserts.

For information on how to choose cellular polycarbonate, see the next video.

The comment was sent successfully.