All about geogrid

Today, when arranging the local area, laying the roadbed and building objects on uneven sections, they use geogrid. This material allows you to increase the service life of the road surface, which further significantly reduces the cost of repairing it. The geogrid is presented on the market in a huge assortment, each of its types differs not only in the material of manufacture, technical characteristics, but also in the method of installation, and the price.

What it is?

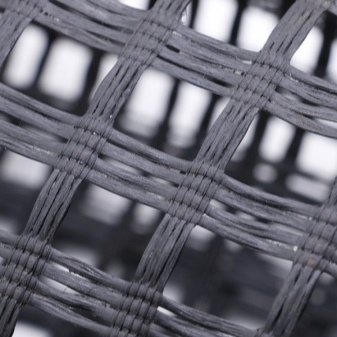

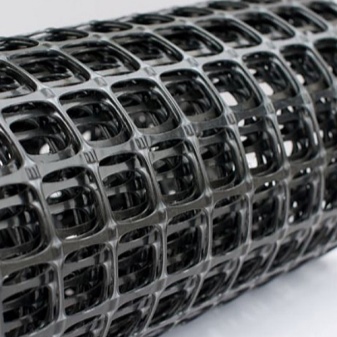

Geogrid is a synthetic building material that has a flat mesh structure. It is produced in the form of a roll with a size of 5 * 10 m and has high performance characteristics, in many respects surpassing other types of nets in quality. The material contains polyester. During the production process, it is additionally impregnated with a polymer composition, so the mesh is resistant to freezing and withstands tensile loads along and across 100 kN / m2.

The geogrid has a wide range of uses, for example, a mount made of this material prevents weathering and leaching of fertile soil on slopes. This material is also used to reinforce the roadway. Now on sale you can find a geogrid from different manufacturers, it can differ in the height of the edge, which varies from 50 mm to 20 cm. Installation of the mesh is not very difficult.

It is only required to correctly perform the calculations and follow all the rules of the relevant technology.

Advantages and disadvantages

Geogrid has become widespread among consumers, since it has many advantages, the main of which is considered long service life. In addition, the material has the following advantages:

- high resistance to temperature extremes (from -70 to +70 C) and to chemicals;

- simple and quick installation, which can be done by hand at any time of the year;

- wear resistance;

- ability to withstand uneven shrinkage;

- environmental safety;

- flexibility;

- resistance to microorganisms and ultraviolet rays;

- convenient to transport.

The material has no drawbacks, except for the fact that it is picky about storage conditions.

An improperly stored geogrid can lose its performance and become prone to external influences and deformation.

Views

Polymer geogrid, supplied to the market for reinforcing slopes and reinforcing asphalt concrete, is represented by several types, each of which has its own characteristics of operation and installation. According to the material of manufacture, such a mesh is subdivided into the following types.

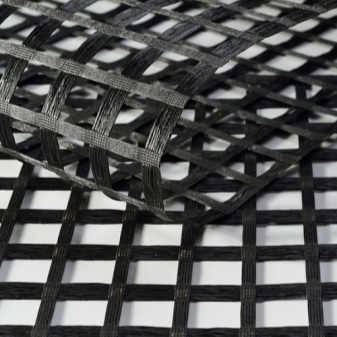

Glass

It is produced on the basis of fiberglass. Most often, such a mesh is used to reinforce the roadway, since it is able to reduce the appearance of cracks and prevents the weakening of the base under climatic influences. The main advantage of this type of mesh is considered to be high strength and low elasticity (its relative elongation is only 4%), due to this it is possible to prevent the coating from sagging under the influence of high pressure.

The disadvantage is the price is above average.

Basalt

It is a mesh made of basalt rovings impregnated with a bituminous solution. This material has good adhesion and high strength characteristics, which ensures the durability of the road surface. The main advantage of the basalt mesh is also considered environmental safety, since raw materials from rocks are used for the manufacture of the material. When using this mesh in road construction, you can save up to 40%, as it costs much less than other materials.

There are no downsides.

Polyester

It is considered one of the most popular geosynthetics and is widely used in road construction. It is durable and resistant to negative external factors. In addition, the polyester mesh is absolutely safe for soil water and soil. This material is produced from polymer fiber, it is a frame of fixed cells.

There are no downsides.

Polypropylene

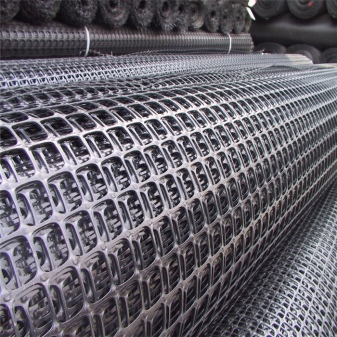

Meshes of this type are used to strengthen and stabilize soil, which has a low bearing capacity. They have cells 39 * 39 mm in size, up to 5.2 m wide and are capable of withstanding loads from 20 to 40 kN / m. The main feature of the material is considered water permeability, due to this, it can be actively used to create protective layers and drainage systems.

There are no downsides.

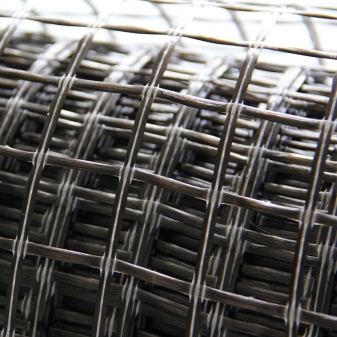

SD mesh

Has a cellular structure and is produced from polymer materials by extrusion... Due to its high performance properties, it is ideal for the manufacture of a reinforcing layer. It is often used in road construction as a layer separator between sand, gravel and soil. Geogrid SD is produced in the form of rolls with a mesh size from 5 to 50 mm. The advantages of the material include high resistance to negative environmental factors, high and low temperatures, mechanical damage and high humidity, minus - exposure to ultraviolet rays.

Also found on sale plastic geogrid, which is a kind of polymer. Its thickness does not exceed 1.5 mm. As for performance, it is a durable material that can be purchased at an affordable price.

Geogrid also classified by orientation of spatial nodes and it happens uniaxial (the size of its cells ranges from 16 * 235 to 22 * 235 mm, width from 1.1 to 1.2 m) or biaxially oriented (width up to 5.2 m, mesh size 39 * 39 mm).

May differ material and manufacturing method. In some cases, the geogrid is released by casting, in others - weaving, much less often - by the nodal method.

Application

Today the geogrid has a wide scope of use, despite the fact that it only performs two main functions - separating (serves as a membrane between two different layers) and reinforcing (minimizes deformation of the canvas).

Basically, this building material is used when performing the following works:

- during the construction of roads (to strengthen asphalt and soil), the construction of embankments (for weak foundations of the subgrade and fortification of slopes), when reinforcing the foundations (a crack-breaking layer is laid out from it);

- when creating soil protection from leaching and weathering (for a lawn), especially for areas located on slopes;

- during the construction of runways and runways (reinforcing mesh);

- during the construction of various earth structures (a biaxial transverse stretch is made from it and attached to the anchor) to improve the mechanical properties of the soil.

Manufacturers

When buying a geogrid, it is important not only to take into account its price, performance characteristics, but also manufacturer reviews. So, The following factories have proven themselves well in Russia.

- "PlastTechno". This Russian company is known for its products in many countries of the world and has been on the market for over 15 years.The main part of the products manufactured under this trademark are geo-synthetic goods, including the geogrid used in various fields of construction. The popularity of the geogrid from this manufacturer is explained by its high quality and affordable price, since the plant focuses on Russian buyers and domestic prices.

- "Armostab". This manufacturer specializes in the production of a geogrid for strengthening slopes, which has proven to be the best operational characteristics, in particular, it concerns high wear resistance, resistance to temperature extremes and high humidity. Affordable price is considered one of the main advantages of the products, which allows purchasing material not only for wholesale buyers, but also for owners of suburban areas.

Among foreign manufacturers, special attention deserves company "Tensar" (USA), which, in addition to producing various biomaterials, is engaged in the manufacture of a geogrid and supplies it to all countries of the world, including Russia. The uniaxial UX and RE grid, it is made of high quality ethylene and is a premium class and therefore expensive. The main advantage of the mesh from this manufacturer is considered to be a long service life, strength, lightness and resistance to negative environmental influences. It can be used to reinforce slopes, slopes and embankments.

The triaxial mesh, consisting of polypropylene and polyethylene layers, is also in great demand; it provides the roadway with strength, endurance and ideal isometry.

Styling features

Geogrid is considered the most common building material, which is characterized not only by excellent performance, but also by simple installation. Installation of this material is usually carried out by the method of longitudinal or transverse rolling of rolls along a slope.... In the case when the base is flat, it is best to lay the mesh in the longitudinal direction; to strengthen the summer cottages located on the slopes, lateral rolling of the material is well suited. Reinforcement of the roadway can be carried out in both the first and second ways.

Installation work with transverse by laying method start from the edge, for this you need to cut the canvases of a certain length in advance. When rolling the net in the longitudinal direction, make sure that the overlap is 20 to 30 cm. The web is fixed every 10 m using staples or anchors, which must be made of strong wire with a diameter of more than 3 mm. We must not forget about fastening the roll in width, it must be fixed in several places. After laying the geogrid, soil 10 cm thick is laid out on top, the layer must be uniform in order to provide the soil cover with the desired moisture regime.

In summer cottages, during heavy rains, water often accumulates, which stands on the surface. This is due to the underground water table, which prevents water from being absorbed into the soil. To prevent this, it is recommended to drain the surface by laying a drainage ditch lined with geogrid. The material can be rolled out only on a previously prepared and cleaned surface of the base, and if the width of the ditch exceeds the width of the roll of material, then the edges must be overlapped by 40 cm.After the work is completed, it is necessary to wait at least a day and then start filling with soil.

During the construction of the roadbed, the geogrid is laid on a base previously treated with bitumen. This ensures a better adhesion between the cover and the material. If the volume of work is small, then laying can be done manually; for a large volume, where a geogrid with a width of more than 1.5 m is used, you need to use special equipment.After completing the installation work It is also important to provide a transfer corridor for the passage of heavy equipment, since at first the movement of trucks is not allowed on the surface laid out by a geogrid. Additionally, a layer of crushed stone is laid on the geogrid, it must be distributed evenly using a bulldozer, then the base is rammed with special rollers.

You can learn more about the road geogrid in the next video.

The comment was sent successfully.