Cultivators for continuous tillage: features and selection

For continuous cultivation, a cultivator can be used, but of a special type. It is used before sowing, if it is necessary to bury the remnants of the grass or simply level the soil surface in one pass of the technique.

Feasibility of use

This type of cultivator can be used for different types of soil processing:

- special;

- solid;

- inter-row.

If we compare the technique with a plow, then there is one significant difference. - during the operation of the cultivator for continuous cultivation, the soil layer does not turn over, the soil is only loosened up. The bottom layer is simply moved upward, the layer is affected 4 cm deep. It is painted, and the earth is mixed. Thus, all plant residues are immersed in the soil, it is fertilized naturally, the surface is leveled simultaneously with these processes.

Thanks to this processing:

- moisture does not evaporate from the lower layers of the soil;

- the earth warms up faster;

- the remains of the plant rot faster;

- access to useful microelements in the soil opens.

Design

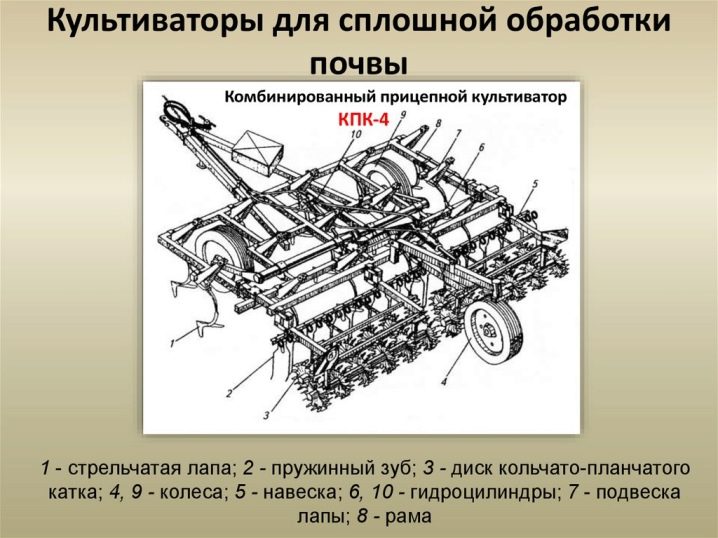

Several assembly units are provided in the cultivator device, which can be considered the main ones:

- frame or frame on which all other elements are attached;

- steering column;

- working bodies;

- a system responsible for fastening discs, knives;

- wheels, which can be both rubber and lugs made of metal;

- engine;

- reducer;

- mechanisms responsible for starting the cultivator and changing operating modes;

- organs responsible for adjusting the immersion depth.

The most used working bodies are:

- loosening paws;

- cutters;

- disks;

- racks that can be spring-loaded or rigid.

Classification

If we classify such a technique by the type of clutch, continuous cultivators can be:

- trailed;

- hinged.

Cultivators of this type are used on any land plot, in terms of size and type of soil. At the same time, the upper surface is discarded, crushed and buried, then the soil is leveled and compacted.

The immersion depth can be adjusted, the main task of such units is to destroy weeds before sowing, so the cutters do not sink deeply. Trailed cultivators are easy to use and maintain. The levers are switched by the operator quickly, during operation the equipment is easily aligned longitudinally and transversely. Thanks to the presence of a rigid hitch, the attachment is lifted together with the control system. The working bodies are practically not clogged with plant residues. Mounted cultivators are used when incomplete crushing of solid soil fragments is required. After processing with them, moisture remains in the ground for a long time.

Models

In this category of goods, Belarusian units from "Kubanselmash" have proven themselves well.

In the lineup:

- KSO-4.8;

- KSO-6.4;

- KSO-8;

- KSO-9.6;

- KSO-12;

- KSO-14.

The equipment of the KSO series is used for soil cultivation before sowing, as well as plowing. On average, the cutters of these cultivators are capable of sinking into the ground to a depth of 10 cm. The technique is used in different regions of the country, regardless of the climatic zone. Their effectiveness can be traced even on soil that is prone to erosion. Supplied complete with double tandem roller and leveling bar.A single roller or a three-row spring harrow can be supplied as required.

The KSO-4.8 cultivator is capable of cultivating up to 4 hectares of land in an hour of operation, its working width is four meters. The working depth is adjustable by the operator and can range from 5 to 12 centimeters. The speed at which the equipment is moving is 12 kilometers per hour. The total weight of the structure is about 849 kilograms.

KSO-8 is used for steam treatment or pre-sowing. The manufacturer can complete his unit with an additional device for mounting the harrow tines. The cultivator frame is made from a shaped tube with thick walls, thanks to which it was possible to create a technique with the necessary margin of safety. The cultivator has replaceable bushings made of polyurethane. The preset loosening depth can be adjusted from 5 to 12 centimeters.

Cultivators KSO-6.4 have a working width of 6.4 meters. The role of the eye is performed by longitudinal and transverse rectangular pipes. The speed of movement of equipment is up to 12 kilometers per hour, while the width of capture of the paws is 13.15 centimeters. The depth to which the cutter can sink is up to 8 centimeters.

KSO-9.6 has similar characteristics, its speed and depth of immersion coincide with the previous model. Spring struts with reinforcing plates are used as working bodies in the design of the equipment. The cultivator's share has a working width of 10.5 cm, if a duckfoot share is installed, it must be completed with an equalizer.

Cultivators KSO-12 have a working width of 12 meters. The power of the power unit inside is 210-250 horsepower, thanks to which the equipment can reach speeds of up to 15 kilometers per hour. The working depth is similar to other representatives of this series - 8 centimeters.

The KSO-14 has the largest working width, it is 14 meters. The immersion depth of the knives is maintained, the engine power is up to 270 horsepower, although the speed remains at around 15 kilometers per hour.

For an overview of cultivators for continuous tillage, see the next video.

The comment was sent successfully.