Types and device of motor cultivators

Working at a summer cottage is not only work, but also pleasure. But this applies only to those cases when the site does not go beyond the standard 6 acres. And if the plot is large, or its owner is an elderly person, then the cultivation of the sown area turns into a heavy duty.

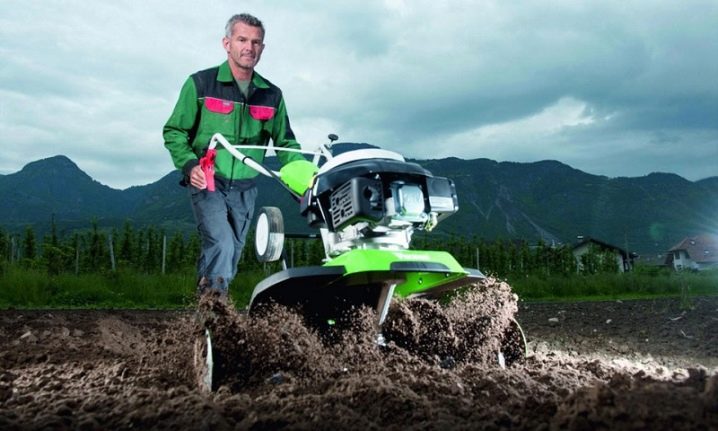

In this situation, a motor-cultivator will truly become indispensable.

Description

A motor-cultivator is an agricultural technique designed for plowing and weeding a land plot. The unit runs on a low power gasoline engine, which varies from 1.5 to 7 liters. with. The loosening depth is 8-25 cm.

Motor-cultivators are available in several versions.

Depending on the mass of the device, there are:

- super light - weighing less than 15 kg;

- lungs - from 16 to 40 kg;

- medium-heavy - 41-60 kg;

- heavy - units weighing more than 60 kg.

Many people believe that a motor cultivator is the same as a walk-behind tractor. However, despite the fact that these are undoubtedly close to each other in terms of design and purpose units, they still have rather significant differences.

The fundamental difference lies in the design of the plant. The walk-behind tractor has a developed system of fasteners, a wide variety of devices, such as a plow, a seeder, a potato digger with a potato planter, a harrow, a mower, a snow blower and many others. At its core, A walk-behind tractor in terms of its functionality is a mini-tractor without a separate driver's seat. A motor-cultivator has a limited set of options; it can be used exclusively for cultivating the land.

As a rule, motor cultivators are equipped with an additional electric drive, the main advantage of the electric model is the absence of harmful exhaust, which makes the device a faithful assistant when working in greenhouses and greenhouses, as well as near the house.

Keep in mind that such a cultivator is connected to an electric current and a power outlet, so all work should be done very carefully so as not to damage the cable with the sharp blades of the cutter.

The cultivator design includes the following elements:

- frame;

- diesel or gasoline engine;

- fuel tank;

- U-shaped handle with unit control buttons;

- rotor for fixing cutters;

- special bracket from the coulter attachment;

- wheels.

How to choose?

When choosing a motor-cultivator, first of all, proceed from the characteristics of the cultivated land plot, pay special attention to the type of soil and the size of the area, as well as the parameters of the engine and fuel consumption.

- As for the size of the plot, everything is simple here - the smaller the sown area, the more maneuverable your machine should be. Moreover, the more complex the land he needs to cultivate, the more powerful the engine should be. Traditionally, this figure varies from 1.5 to 10 liters. with., but most often they produce motoblocks with a capacity of 4 horsepower, a little less often - 5 and 6 liters. with.

- Most often, vertical gasoline engines are hung on motor-cultivators, which can be two-stroke and four-stroke with a power take-off shaft, as a rule, the former are put on lightweight models, and the latter - on products of a heavy class, when the issue of reasonable fuel economy is fundamentally.

- Depth parameters - motor cultivators loosen the soil at a depression of 15-35 cm, while the working width can be from 15 to 95 cm, depending on the modification.

- Devices for maneuvering - there can be handles with buttons placed on them, as well as gearshift levers, clutch levers and other elements.

- As for the clutch, the most practical is considered to be clutch and gear reducers, they are attached to heavy equipment. In the middle class, the belt mechanism showed itself best, but the light ones are quite enough with a worm gear and a conventional centrifugal clutch with a chain gear.

- Safety is considered an important factor when choosing a suitable model; preference should be given to products with a protective casing - it protects people from falling clods of earth while operating a motor cultivator.

In addition, it is advisable to purchase models equipped with protective discs - this way you will protect green plantings from breaking during work between the beds.

- Special attention should be paid to cutters, they must be made of steel. There are saber-shaped devices and the so-called crow's feet. The first ones are made of carbon steel, are characterized by increased strength and, as a rule, are included in the basic set. The latter are optimal for the cultivation of virgin lands, however, their strength characteristics are slightly lower, so they often break.

Manufacturers

Most of the cultivators are produced in European countries, as well as in Japan, China and Russia.

Among European brands French motor cultivators Pubert, Italian Benassi, German MTD and Danish Texas have received consumer recognition... Among the most popular American units are Craftsman, as well as Partner, and from Japanese brands the palm belongs undividedly to Honda.

In our country, motor-cultivators of the brands "Krot", "Leader", "Favorit", "Neva" and "Master" are produced.

Separately, we should dwell on the Chinese units. China is a country where there are a lot of small farms, so motor-cultivators are widely used in the country.

Today, Chinese motor-cultivators are the cheapest in the world, but they have a number of disadvantages.

First of all, the units are made from metal of our own production, which, unfortunately, leaves much to be desired, therefore the machines are significantly inferior to analogues from other countries in terms of strength and wear resistance parameters. The same can be said for the plastic elements, with this disadvantage applied to products manufactured under the brand names of well-known American and Japanese brands, manufactured under the supervision of parent companies.

The only exceptions to this rule are motor cultivators assembled from spare parts made at European and Japanese enterprises.

As practice shows, most often gear wheels, cylinder rings and chains break... Quite often it happens that the fasteners in the nodes and the carburetor are made in bad faith.

At the same time, a large number of small enterprises operate on the market of this country, which simply copy old samples of well-known brands, as a rule, they are made for export to Russia and other CIS countries, such cultivators usually bear Slavic names - "Zubr", "Aurora" , "Sadko" with "Bulat" as well as "Giant", "Proton" and some others, they cost 2-3 times cheaper than their counterparts from European countries.

However, all of the above does not mean that Chinese products are necessarily of low quality and short-lived. In fact, there are large brands in this country, whose products have received high ratings from consumers around the world, which is confirmed by European quality standards.

This primarily applies to products manufactured under the Weima brand - these cultivators have been successfully exported to more than 50 countries for many years.

Principle of operation

The main task of the cultivator is reduced to loosening the earth with star cutters.Unlike the same plow, the cutters do not turn the soil layer, this protects the soil from erosion and is considered a much more reliable and modern way of agricultural processing of the site.

The motor-cultivator is controlled by the operator using the buttons located on the handle. The design does not provide a seat for people.

On the handle there are buttons for a mechanical clutch, as well as a speed switch, including forward and reverse. The presence of the latter, by the way, is very important - it is necessary in situations where the cultivator is stuck in heavy soil, then, in order to avoid breakage of parts, the machine should be fed back with a low gear using the reverse gear.

Usually, active horizontal cutters with knives are attached to them, they are able to dig ditches for planting potatoes, which can then be easily backfilled with earth - for this you just need to swap the left and right disc cutters.

The opener is considered to be a very important structural part of a motor-cultivator; it is a metal rod made on a frame near the cutters. Its tasks include braking actions, thanks to which the cutters go into the ground to the maximum.

By setting one or the other length of the opener, you can also adjust the parameters of the cut of the seam of the earth. If you install two openers at once on the cultivator, you can easily maneuver the device by pressing either the right or the left panel buttons.

You can get acquainted with a detailed review of the MTD brand motor cultivator by watching the video below.

The comment was sent successfully.