Tedder rake: features and best models

The tedder rake is an important and essential agricultural equipment used for hay production on large livestock farms and private farms. The popularity of the equipment is due to its high performance and ease of use.

Device and purpose

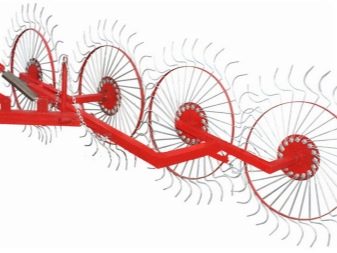

The tedder rake replaced the conventional rake, which was used to rake the grass after mowing. With their appearance, it was possible to mechanize the hay harvesting process and completely eliminate the use of heavy manual labor. Structurally, the tedder rake is a two-section wheel-finger design, in which the sections are able to work both together and separately. Each unit consists of a frame, support wheels and rotating rotors, which are the main working parts of the unit. The rotors are fastened to the frame by means of tapered bearings, and the torque required to rotate them is transmitted using the propeller shaft of the tractor. The support wheels are set in motion due to adhesion to the ground while the tractor is moving.

Each of the rotors is equipped with raking fingers made from high strength steel. Depending on the model, the number of rotor fingers can be different - from 32 to 48 pieces. The rotor wheels are fastened by means of a spring suspension, which prevents mechanical damage to the working elements and prolongs the service life of the unit. The rotors are located at a certain angle in relation to the line of movement of the tractor, and thanks to the rotating adjustment lever, they can be raised or lowered to the height required for more efficient work. The same lever is used to transfer the unit to transport mode, when the rotors are lifted high above the ground so as not to damage during movement.

The tedder rake performs 3 important functions at once. The first is to rake the cut grass, the second is to turn over the already dried grass, which prevents it from overheating, and the third is to form neat swaths that are convenient for transportation and storage.

Principle of operation

The process of swathing with a tedder rake is quite simple and consists in the following: the movement of the unit across the field is carried out thanks to a tractor, which can be either a conventional tractor or a mini-tractor. The rotor wheels begin to rotate, and their fingers rake the cut grass in such a way that the grass captured by the first rotor is pulled slightly to the side and transferred to the second and subsequent wheels. As a result, after the grass passes through all the rotors, uniform and voluminous swaths are formed, each of which is already well loosened and breathable. This technology of collecting grass allows the hay to dry quickly and not overheat. In this case, the width of the rolls can be adjusted using the front and rear guy lines.

The next function of the machine - tedding hay - is as follows: the angle of the position of the rotors relative to the ground is slightly changed, due to which the grass collected with the help of the fingers does not flow to the next wheel, as it was in the previous case, but swells and remains in the same place.Turning over the dried grass is achieved by advancing the section of the machine along the formed swath, which is slightly pushed back and turned over. The operation of the rake-tedder is carried out by one tractor driver, and due to the simplicity of the design and the absence of complex components and assemblies, the repair and replacement of failed parts can be performed in the field.

Advantages and disadvantages

Like any agricultural equipment, the tedder rake has its pros and cons. The advantages include the simplicity of the equipment in operation, as well as its undemandingness to routine maintenance. A long service life of the units is also noted, reaching ten years. In addition, one can note the high reliability and strength of the structure, which is based on a powerful drawbar and a sturdy frame, as well as the ability to conveniently adjust the position of the rotors and quickly switch to the inoperative position, which is achieved thanks to the hydraulic mechanism. The performance of the tedder rake depends on the model and averages 7 ha / h.

The disadvantages include the slow operation of the equipment in the corner sections, as well as the not very reliable undercarriage. However, the latter problem is a disadvantage of most trailed agricultural implements for various purposes.

Varieties

The rake-tedder is classified according to several criteria.

- Tractor type. On this basis, two categories of units are distinguished, the first of which is presented in the form of attachments or trailed equipment for tractors, and the second has much smaller dimensions and is intended for walk-behind tractors.

- Roughing method. According to this criterion, two groups of devices are also distinguished: the first provide lateral, and the second - transverse formation of rolls. Moreover, the "transverse" models have a very large grip, reaching 15 meters.

- Design. There are three types of rake-tedders on the modern market: wheel-finger, drum and gear. The first ones are equipped with a rotor wheel damping system, which makes them an indispensable type of equipment when working on fields with difficult terrain. Drum models are robust and durable devices, the principle of which is based on the rotation of rings independent of each other. Gear units are driven by a gear train and are capable of changing the angle of rotation and inclination of the teeth.

- Number of rotor wheels. The most common types of equipment are four- and five-wheeled models.

The four-wheel tedders are designed to work with tractors from 12 to 25 hp. with. and walk-behind tractors. The tedding width of such models is 2.6 m, and the grass coverage is 2.7 m. Such devices weigh about 120 kg and are capable of operating at a speed of 8 to 12 km / h.

Five-wheeled samples of tedders are aggregated with any type of tractor, excluding low-power walk-behind tractors. They have slightly higher performance characteristics when compared with the previous type. So, the length of the structure reaches 3.7 m, and the rotors are located obliquely. This design allows you to increase the efficiency of tedding and eliminate losses during raking of grass. The models weigh 140 kg and have a working speed of 12 km / h.

In addition to the ones presented, there are two-wheeled models, one of which will be discussed below.

Popular models

The domestic market of agricultural equipment is represented by a large number of rake-tedders. Among them there are both foreign units and Russian-made devices.

The most popular of them is the GVK-6 model. The product is manufactured at the enterprise of the correctional institution No. 2 in the city of Ryazan and is actively exported to neighboring countries. The equipment can be aggregated by means of wheeled tractors of classes 0.6-1.4 and fixed to them like a conventional hitch.A feature of the GVK-6 tedder is its ability to work with damp grass, the moisture content of which reaches 85%. For comparison, Polish and Turkish counterparts can only cope with 70% humidity.

The length of the unit is 7.75 m, width - 1.75 m, height - 2.4 m, and the working width reaches 6 m.The width of the rolls is 1.16 m, height 32 cm, density - 6.5 kg / m3, and the distance between two adjacent rolls is 4.46 m. In the working position, the device is capable of moving at a speed of up to 12 km / h, and during transportation - up to 20 km / h. The GVK-6 model is distinguished by its high productivity and processes an area of up to 6 hectares per hour. The weight of the rake is 775 kg, the cost of one section is 30 thousand rubles.

The next popular model GVR-630 comes off the assembly line of the Bobruiskagromash manufacturing plant. The unit is also used in the form of a tractor trailer, and is connected to the tractor through a hydraulic system and a power take-off shaft. The working unit of the device is of Italian origin and is presented in the form of an asymmetric collapsible frame with two rotors mounted on it. Each rotor has 8 tine arms fixed to it with a hub. Each tine arm has six right-angle tines. The height of the rotors above ground level is adjusted by means of a hydraulic drive located on the left rotor wheel, which makes it possible to rake fields with a slope and difficult terrain.

The principle of operation of this model is somewhat different from the principle of operation of models of other brands and consists in the following: with multidirectional rotation of the rotor wheels, the teeth collect the cut grass and put it in the rolls. When the direction of rotation is changed, the machine, on the contrary, begins to stir the mowing, thereby increasing air exchange and accelerating the drying of the grass. The model features a large working width of up to 7.3 m and a high raking capacity of 7.5 ha / h. This is 35% higher than the average of most other models. In addition, the device is very maneuverable and, in comparison with other models, can reduce fuel consumption by 1.2 times. Such a rake weighs 900 kg, and their cost is within 250 thousand rubles.

You should also pay attention to the rake GVV-6A manufactured by the plant "Bezhetskselmash"located in the Tver region. The model is highly appreciated by Russian and foreign farmers, and competes with Western models in the modern market. The unit is capable of processing 7.2 hectares per hour and has a fairly high operating speed of 14.5 km / h. The gripping width of the device is 6 m, and the roller width during raking is 140 cm. The weight of the device reaches 500 kg, the cost is about 100 thousand rubles.

User manual

When working with a tedder rake, a number of recommendations should be followed.

- The attachment should be carried out with the tractor engine off.

- Before starting work, it is necessary to check the connection between the rake and the tractor, as well as the presence of a safety cable attached to the tractor crossbar. You also need to make sure that the hydraulic system is tight and the propeller shaft is in good working order.

- During stops, the gear lever must be in neutral and the power take-off shaft (PTO) must be disconnected.

- It is forbidden to leave the tractor with the engine and PTO on, as well as with the parking brake turned off, unattended.

- Adjustment, cleaning and maintenance of the tedder rake should be carried out only with the tractor engine turned off.

- On bends and difficult terrain, the speed of the rake should be reduced to a minimum, and for particularly sharp bends, it is imperative to turn off the PTO.

How the tedder rake works, see the next video.

The comment was sent successfully.