Lawn mower knives: requirements, varieties, mounting features and selection

A knife is no less popular than a fishing line or cord, a working tool for a mower. If in the trimmer you can do with fishing line or cord, then the knife is basically a cutter for brushcutters, the power of which is noticeably greater than that of trimmers.

Purpose and requirements

The purpose of the mower cutter is to cut the grass evenly and neatly in large quantities. In one session, when mowing one hundred square meters of a plot, you can collect tens of kilograms of grass. If the lawn mower has the function of shredding (mulching), such a knife should also chop the grass. The mower's cutter is designed so that its blades create upward thrust for the grass that has just been cut. She carries this grass into the collection box.

The best alloy for a mowing knife is stainless steel. Moreover, it must have a hardness of at least 55 units on the Rockwell scale. A lower hardness value will quickly dull the cutter - especially when cutting weeds and trimming bushes. Since the cut grass contains not only moisture, but also other active components, ordinary steel would quickly become covered with a brown coating after the very first mowing session. Stainless steel, creating on its surface a chromium oxide that resists corrosion (chromium is also included in the list of alloying additives), does not allow the knife to rust.

Important! In addition to being tough, the cutter must also be sturdy. If, during work, he stumbles upon a stone, then it should not fly apart.

Varieties and sizes

Lawn mower consumables - knife (line, cord) and drive belt. The types of knives used in modern mowers are rotary and cylindrical. The latter are also called drum or spindle. Lawn mower cutters are generally limited by the 33–51 cm OD range. You can pick up specific sizes, for example, 40 and 46 cm, in any store. The owner's manual for each lawnmower model indicates the recommended size. Taking a knife with a smaller diameter, you will reduce labor productivity due to a narrower "track" mowed in the grass, that is, the number of rows traversed by the mower will increase - and you are unlikely to move faster.

Too large a knife will "plant" the engine speed, which will lead to more wear on the engine.

Finally, the material of the cutter is critical for safety... Most knives are made from stainless steel, but there are also plastic knives. The fact is that when the cutter hits a large stone, the debris of steel can hurt you with a ricochet. A blow from a plastic debris is much more harmless - unless it hits the eye. The plastic knife is the choice of owners of mowers with a curved flexible shaft. The utility knife for lawn mowers not only cuts grass and bushes, but also crumbles them - due to the larger number of blades (up to 8). Finely chopped grass will do as a top dressing (mulch) for the lawn.

Blade and adapter shapes

If this is a simple blade cutter, then there can be several blades - but no more than 8. The shape of the blades of such knives can be as follows:

- simple (in the form of rectangular ends);

- rounded (the extreme edges have a smooth curvature);

- pointed (in the form of a wide dihedral bayonet).

Bladeless knives - a cutter that resembles a circular saw for wood. These knives are also called disc knives. The number of teeth is up to tens. They vaguely resemble a bicycle sprocket, the teeth of which have been sharply sharpened and changed the direction of the cut. There is a special type of cutter, in which the cutting part is not star-shaped, but stepped. It resembles rounded and curved steps, also evenly spaced. Their sheer parts are sharply sharpened. The height of the teeth or "steps" reaches several tens of millimeters.

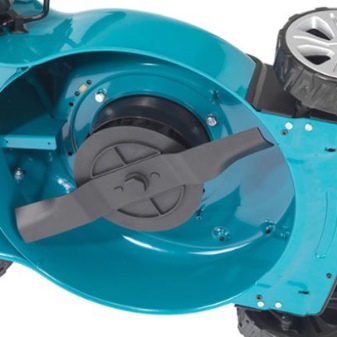

The adapter is a two-blade knife adapter that fits onto the motor shaft. From the side of the knife, it has retaining rods threaded through the holes of the cutter itself. The whole structure is tightened with a central bolt. Simply put, an adapter is a knife holder. On the reverse side, it has toothed grooves that match the teeth of the shaft. It is selected according to the inner diameter of the central hole of the knife (for example, 22 mm).

What should be the sharpening angle?

Lawn mower cutters are always sharpened at a 30-degree angle. A smaller angle will make the blade too thin, like a razor rapier - it will quickly serrate, bend, it can only cut short grass. Weeds and bushes are guaranteed to "ruffle" the edge. Too large an angle will lead to the fact that the knife will hit and break bushes more, tear the stalks of grass - than cut off both. In addition, the point should be sharpened on one side - and only slightly, barely noticeably sharpened on the opposite side.

How to fix and replace?

The knife should be changed every quarter or during the growing season, although sometimes it should be changed sooner. Installing the knife is as follows:

- if the mower is in operation, suspend it; for electric braids, it is enough to turn off the power (cord from the outlet, disconnect the battery); petrol mowers are disconnected from the key, unused fuel is drained back into the canister;

- turn the mower to one side and remove the grass catcher;

- clean off the ground and grass adhering to the working parts from the knife and the protective visor;

- remove the visor (protective cover) of the knife; it holds back the grass scattered in all directions (when mowing);

- unscrew the mounting bolt using a wrench or a head, the knife should not turn, it itself is attached to the adapter; it is recommended to wear work gloves before removing the knife so as not to cut yourself;

- insert a new (preferably exactly the same) knife and tighten the bolt tighter, when it is loosened, the machine vibrates, or the blade itself may fly off.

If vibrations appear, but there is no replacement knife, it is necessary to balance the old one. Remove the knife and check its balance by hanging it on a screwdriver or nail with a large head. For this, the working part of the screwdriver is threaded through the central hole of the cutter itself. If there is an imbalance - one particular point will tilt, in this case, grind off a little metal. With repeated sharpening, the mass of the point that outweighs the others will decrease, and the center of mass will shift to its place. After balancing is complete, reattach the adapter and tighten the modified torch. If the adapter has a key holding it on the motor (gearbox) shaft, do not forget to press it into place.

If you find a previously purchased replacement cutter, install it immediately. In some cases, the holder also wears out - it needs to be replaced.

Popular manufacturers

Like lawn mowers and accessories for them, for example, knives, are produced by popular manufacturers, the best of which are the following:

- Bosch;

- Gardena;

- Craftsman;

- Champion;

- Makita;

- Hyundai;

- Daewoo;

- Honda;

- "Bison";

- Interskol;

- "Anchor".

Selection Tips

First of all, the knife must be strong and durable. The best material for knives is stainless steel of the correct thickness, and not, for example, black steel with a spray of stainless steel or galvanized iron. Sometimes manufacturers indicate the grade of stainless steel, for example, AISI 304. The knife is not a detail worth saving on.

For portable lawn mowers, the minimum solution is a two-knife blade. In other words, you should choose a knife with two cutting edges. He will cut the grass - but he will not chop it up. To mulch the grass, buy an eight-point cutter. The optimum sharpening angle is approximately 30 degrees. You will quickly learn to recognize these knives.

The thread of the rotor pins, on which the cutter is put on with its mounting holes, does not matter. Usually it is left, if the knife turns to the right - and vice versa. This helps to avoid loosening the nuts and the knife coming off at full speed.

If your choice nevertheless fell on plastic knives, look for unbreakable and rather hard plastic that retains the factory sharpness of the cutting edge longer. Such one does not fly apart in crumbs from the slightest impact when transporting or rolling the lawn mower to the place where the lawn mowing begins.

Common breakdowns

Most often, the malfunctions are as follows: the mower does not cut the grass or does not turn on at all.

The mower does not cut the grass

There are two possibilities here.

- The knife is blunt or broken. Sharpen it with a file, grinder, on a grinder (you need a flat-cylindrical grindstone) or on a machine (or drill) using emery wheels. Check torch balance.

- The cutter itself is not set correctly. Set a gap in the roll mower between the rotating cylinder and the blade of the knife equal to the thickness of the sheet of paper.

The rotor with the knife does not spin in the mower

There are several options here.

- The knife itself is stuck. Pull the grass and dirt out from under it and rotate the cutter itself. It must rotate freely, without scratching or rubbing against the protective casing.

- The drive belt is broken. Check the integrity of the belt. A worn out, "sprinkled" belt must be replaced.

- Power cut. Repair the broken wire in the cord. Replace the cord if the insulation is broken.

- The switch does not work. Check that the switch is working, try switching the mower off and on. If the switch is unusable (melted, burned contacts), replace it.

- The supply voltage in the network has disappeared. Check for possible tripping of the circuit breaker on the electrical panel.

- The plug is not included in the socket. Connect the plug to the socket (if pulled out).

- The fuse in the device has blown. Check it with a tester (multimeter). Replace the defective fuse if necessary.

- The mower's thermal protector has switched off the motor. Wait for the motor to cool down after mowing the grass.

After checking all parts and assemblies, finding a fault, start the mower. Most likely your problem will be resolved. Fuel lawn mowers either have the carburetor (or drive) or run out of fuel. Often, unstable operation of the motor requires finding and eliminating the breakdown of a number of parts before it is possible to find and replace the faulty one.

How to replace the knife on the lawn mower, see the video.

The comment was sent successfully.