Features of Reno mattresses

Reno mattresses are a type of gabion, which is widely used in modern construction of coastal fortifications, bridges, highways, to protect pipelines, as well as in landscape design. This article provides an overview of the technical characteristics of such structures, gives advice on choosing Reno mattresses for strengthening slopes and other surfaces prone to landslide and erosion destruction.

Peculiarities

Reno mattresses (mattress-mattress type of gabions) constitute a solid mesh construction made of double twisted steel wire, filled with broken stone, crushed stone, pebbles or other similar materials.

The history of the use of gabion mattresses goes back centuries: there is evidence that the first wicker containers filled with stones were invented by the great Italian artist and architect Leonardo da Vinci, who first used these structures to strengthen the foundations of the church. Later, gabions were actively used by the military as defensive means, saving soldiers from shells, and even later, these structures re-entered peaceful life, helping to prevent erosion of the banks and saving people from flooding.

In the 19th century, the Italian company Maccaferri used gabion mattresses to strengthen the banks of the flooded Reno River, which is located near Bologna, after which it patented this type of design.

Since then, such structures have received the name Reno. Since then, it is this type of gabion that has been widely used for facing river and sea banks, as well as for protecting the sea and river bottom from erosion. Industrial gabions produced in modern factories are box-shaped structures in the shape of a parallelepiped. They have a rigid metal frame made of high-strength wire or steel bars welded in a lattice form. Large stones, cobblestones, river pebbles or crushed stone are laid inside the frame right at the construction site.

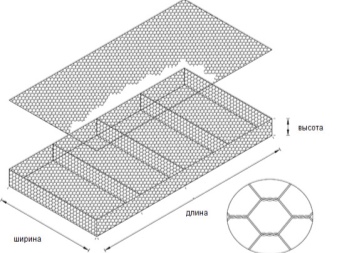

A feature of Reno mattresses is their large base area compared to rectangular gabions and a small height - about 17-30 cm.

The advantages of gabion structures are ease of installation, long service life, relatively low construction costs, resistance to corrosion and aggressive chemical attack. Reno mattresses are excellent drainage material, while not collapsing and retaining their original characteristics for an unlimited period.

Specifications

Let us dwell in more detail on the design of mattress-type gabions. These flat containers with a large support area and shallow depth consist of a galvanized mesh with a cellular structure.

Metal grid made of double-twisted wire, which has a special GALMAR coating, or galvanized, due to which the mattresses Renault has excellent corrosion resistance. If mattress gabions are supposed to be used in an aggressive environment, after galvanizing or applying a special coating, an additional layer of polyvinyl chloride is applied to the steel wire of the frame.

This sheath protects the wire from chemical and mechanical damage.

Hexagonal mesh steel mesh resemble a honeycomb in shape. The edges of such gabion structures are connected with a wire with a larger cross-section than the wire of the mesh itself. Inside the gabion container is divided special diaphragms, that is, with partitions located at a distance of 1 m from each other. With the help of such partitions, the best strength and rigidity of the structure of Renault mattress gabions is achieved. In the regulatory documents used by builders to strengthen the roadbed, as well as the banks and slopes, such structures are called gabion-mesh products of the mattress-mattress type and have standard sizes that correspond to GOST.

Such nglossy gabions have a standard width, which for all Reno mattresses is 2 meters - the width of a double mattress. The minimum thickness of such products is 0.17 m, there are also mattress gabions with a thickness of 0.23 and 0.3 m.

Such a strict uniformity of these parameters is dictated by the size of the hexagonal mesh cells.

There is a variety mattress gabions of increased thickness entitled gabions jumbo, their height is 0.5 m. Length gabions Renault may vary within 3-6 m.

The weight of mattress gabions depends only on two indicators: length and thickness, since the width of the products is always the same. In addition, the number of layers of anti-corrosion coating affects the weight of such structures. Thus, Renault's galvanized steel mesh is 2 m long and 0.17 m thick and has a weight of 19.300 kg. The same galvanized steel wire, but with additional coating, weighs 24,700 kg. The Renault mattress is 6 m long and 0.3 m high and weighs 49 and 53 kg, respectively.

Where are they used?

As already stated, mattress and mattress designs use for strengthening the slopes and cones of bridges, in the construction of roads and pipelines, and also as bases for back-ups from larger box gabions. Although Renault gabions have a large surface plane, however, such structures are not suitable for the construction of high walls as an independent element, since, due to their small thickness, such devices do not have sufficient rigidity.

Such flat products easy to lay on the river bottom, also on any uneven surfaces, since they are very plastic and easily take the shape of a relief. Reno mattresses are widely used to strengthen the bottom of reservoirs and shore protection, landslide slopes are lined with them.

Over time, the strength of the structure only increases, since soil is applied inside such containers, plants germinate there and strengthen the entire structure with their roots.

Gradually these gabions become part of the landscape, at the same time protecting it from water and wind erosion.

Instructions

All work on the installation of mattress gabions is carried out strictly in accordance with with the technology of carrying out strengthening works. Before starting to strengthen the cones and slopes, it is necessary to remove loose soil and level and compact the site using special devices: vibratory rammers or vibrating platforms. Also, if necessary, it is worth removing stagnant water on the surface. Facing slopes with mesh mattress gabions is carried out in stages.

- The mesh structure is laid out on the ground, carefully leveling out all the folds.

- The vertical planes are lifted and connected with a wire, keeping the edges perpendicular.

- The resulting Reno mattress is installed in the designated place and connected with a wire to the adjacent blocks.

- A filler is placed inside the mesh box, which is usually large fragments of hard rocks, such as granite, by a third of the volume. Make sure that the size of the stones is 40-200 mm.

- The opposite sides of the gabion are connected with special staples using the twisting method.

- Continue filling the container with an excess of 3-5 cm.

- Close the mesh metal container with the same lid, firmly tying it with wire to the side faces.

During operation, regular checkups such constructions, destroyed blocks are repaired (fill up the filling material, change entire modules, water the green slopes in the absence of rain, especially in the first years after installation). Reno mattresses are chosen when it is required to strengthen large areas. Depending on the task at hand, mattress gabions of one length or another are chosen. The filler material is also very important and depends on the specific purpose.

Care must be taken that the size of its elements exceeds the size of the mesh of the wire mesh.

For more information on Reno mattresses, see the video below.

The comment was sent successfully.