Everything you need to know about bog oak

In the proposed article, it is sorted out what it is - bog oakand how to do it. It is important to understand how it is mined, what is the density of such a rock and other basic properties. Furniture and other products, windows and entire houses made of oak are very valuable constructions, and this topic deserves careful consideration.

What it is?

Bog oak is the most expensive type of wood that exists. For many centuries, real masterpieces have been created from it. But only especially wealthy people could spend the required amount.

Bog oak products have been passed down as a very rich heritage and have been preserved for many generations.

Today, a number of such things are exhibited in museums or have ended up in private collections.

Bog oak first appeared quite by accident. People have discovered oak wood that has spent hundreds of years under water. All such specimens hit the sea before the industrial era, and therefore are environmentally friendly. You can even determine the age of wood in a simple visual way. For 300 years under water, bog oak becomes silvery, and the presence of fawn shades is also noted.

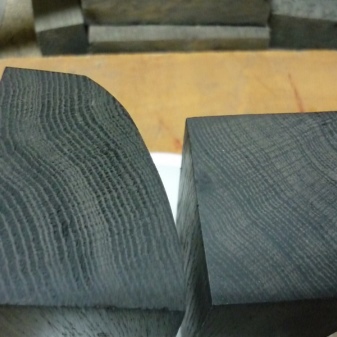

If a tree spends 1000 years under water, it looks very different. Most often, such fragments turn black, however, some of them are purple, and it looks very original... Changes in color are due to the fact that the access of atmospheric oxygen or oxygen dissolved in water stops. The wood is separated from it by a sandy-silt layer.

The increased pressure exerted by the layers of water also means a lot.

As a result, unique chemical reactions occur, a special substance appears - tanninwhich preserves wood in a natural way. Bog oak can be identified not only by color. Real copies of it are very hard, almost as good as stone. This material almost does not rot or dry out. It is not necessary to cover it with any paints and varnishes at all and is even harmful - the original texture of bog oak is too good to hide it.

Basic properties

Even in the pre-war period, it was possible to find out that stained wood contains only 25% of water-soluble substances from the amount that is in the fresh felling products. This change is associated with an increase in the porosity of wood cells and a decrease in their density. As a consequence, the maximum saturation humidity increases. The drying process is balanced.

Therefore, in the process of drying timber, stained boards or blanks dry out absolutely.

Testing with moisture meters has shown that the absolute humidity of natural bog oak exceeds 80%. The density upon reaching a moisture content of 67.7% is 0.88 grams per 1 cm3. According to other sources, it can vary from 800 to 850 kg per 1 m3. For comparison: the density of fresh oak wood in most cases does not exceed 650 kg per 1 m3.

The hardness is as follows:

-

for compression along the fibers - 37 MPa;

-

for splitting along the fibers - 12.8 ± 1.1 MPa;

-

ultimate strength in static bending - from 37 to 47 MPa.

How are they mined and made?

The extraction of bog oak on any large scale is impossible today. Almost the entire volume of this material has already been extracted from the seas and used for its intended purpose. Each find literally becomes an event in the world of woodworking. It turns out to be more difficult, more expensive and longer to search for new copies.Even advanced equipment doesn't help much.

In addition, finding a bog oak in the sea is only half the problem, it is equally important to process it correctly.

This process also requires a huge amount of knowledge, experience and solid investment. Therefore, only a few specialized firms can perform the assigned task correctly. All alternative options for manipulating bog oak, except those based on perfect technology, invariably failed economically after 7-10 years.

Moreover, even a seemingly insignificant mistake can devalue all previous efforts, and the entire batch will be hopelessly lost as lumber. In the CIS, there is not a single enterprise capable of producing more than 1000 m3 of real natural bog oak according to all the rules per season. Apparently, such enterprises are also absent in the far abroad. The extraction and processing of bog oak is carried out using mobile sawmills, which, moreover, have to be transported over long distances using a truck chassis.

Specialized floating craft are necessarily used, which also have to be transported from place to place.

The direct search for bog oak is carried out by special electronic systems. It is also impossible to do without equipment for underwater work. We have, of course, to attract experienced divers. Since the quality and exact characteristics of the incoming material cannot be predicted, this moment must be monitored by continuously trained specialists.

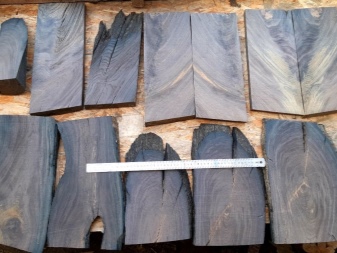

Many disadvantages of the finished raw material can only be detected during sawing.... The final assessment of the quality of bog oak can be given only when the humidity is reduced to 4%. Any conclusions that one tries to draw earlier are inevitably premature and cannot be used to truly assess the performance of a product. Each specific place needs specific equipment. So, on dry shoals, excavators are indispensable; you can lift a tree from a river or lake using floating cranes or specialized excavators.

On small rivers, it is recommended to use skidders. In any case, there are a lot of non-standard situations when working on water. And only trained workers will be able to complete the task quickly enough, without unnecessary risk. After removing the bog oak, you have to work with each specimen individually.

In nature, there are not even two samples with completely identical characteristics.

One more problem - together with bog oak, they inevitably raise a lot of accompanying firewood... When sorting an alloy, everything unnecessary is simply given to other organizations. With a special search for stained raw materials, the solution has to be looked for separately every time. The processing of such raw materials itself is complicated by many factors. Even the best cutting equipment, for example, will wear a lot, and this is not the whole set of problems that will have to be faced.

Therefore, in many cases, it is most correct not to dive into the circle of problems associated with searching, drying, and so on, but to make an imitation of bog oak artificially. A tree trunk is ideal as a raw material - preferably oak, from which all branches and other interfering parts have been removed. In any arbitrary place on the bar or board, a nail is driven in. A short fishing line is tied to it. The main processing is carried out in a glass jar using ammonia - or rather, its solution.

The solution should be overflowed as soon as possible. The bar should be inside the can, but not touch the liquid itself - that is why a nail and a fishing line are needed. The edges of the fishing line are pulled out and the polyethylene cover is put on as quickly as possible. Outside, the fishing line is fixed with ordinary tape. It is wound so that even a small leak of ammonia does not occur. Processing takes 1-3 days, depending on the desired color saturation.

Frozen oak color is obtained after aging for more than 72 hours. The color saturation increases with further aging. The longer it lasts, the deeper the impregnation penetrates. You can get larger stained blanks in large containers. In this case, the ammonia tank should be opened as carefully as possible, inhalation of its vapors is life-threatening.

Another alternative solution is that reproduces, however, only the appearance of natural bog oak. It consists in using wood stain. First, it is smeared with a brush at a slight angle across the fibers. Then longitudinal processing is carried out.

An ordinary paint brush is not very suitable for such processing, it is much better to use a wide "flute". This solution allows you to maintain the elusive tone transition as close to natural as possible.

Water-based stains are absorbed into the wood quickly enough. But in the course of work, drying will be needed, which complicates and slows down the process. But it is possible to achieve a uniform shade. Ethyl alcohol formulations evaporate very quickly. You have to work with them as carefully and strictly as possible in protective gloves.

Application

In construction

Matte bog oak boards are in demand much more than it might seem at first glance. There are at least 5 known areas where this valuable material is used. Using it to build a house in general is about the same as sending a luxurious sports car to ride on steep terrain. It will be easier and more convenient to take the required amount, cash out and burn - if there are any, of course. A more reasonable measure is to equip only individual surfaces and parts of buildings, such as:

-

window;

-

stairs (steps, railings);

-

lower rims of the log house;

-

visual decorations.

In the interior

Furniture and various souvenirs are mainly made from stained wood. All such items inevitably acquire the status of antiques over time. Excellent parquet or other flooring can be obtained from this material. Such a design will have a long service life. Among furniture products, dining tables and kitchen worktops are naturally in greatest demand. But you can, of course, make a wardrobe, a bedside table, a shelf. Even in the interiors of any house, stained will look luxurious and noble:

-

figurines;

-

boxes;

-

decorative figurines.

The comment was sent successfully.