All about yamoburs

During construction work, it is often necessary to drill holes in the ground. In order to get a hole of a certain depth and diameter, a tool such as a yamobur is used.

What it is?

Yamobur is a special device that helps and greatly facilitates the work when drilling the soil. For different types of work, different types of hole drills are used. Variations of this kind of tool start from the simplest primitive models and end with heavy special installations that are placed on the chassis.

Construction is not complete without such a drilling tool, where, first of all, it is necessary to carry out earthworks. With the help of a drill hole, cylindrical wells are formed, which are used for supports or other vertical structures. He is also able to drill for a pile foundation or form holes in the form of a cone. With their help, they green the territory, it is very convenient and quick to make holes for seedlings. And also this tool is used by surveyors if you need to collect geological data.

Hole drills are made of forged steel, powder coated on top. For convenience, some manufacturers equip the steel handle with special rubber pads. Handheld models often feature anti-slip plastic handles that rotate on a metal base for added convenience.

Views

The choice of the required type of auger directly depends on the type of soil on which the work will be carried out. It is important to consider the structure, density of the earth or rocks. For example, some tools can handle rocky ground or sticky clay with ease, but they are not at all designed to drill through frozen ground.

In principle, with the current abundance of varieties of this product, it will not be at all difficult to find the right drilling tool for any type of soil. So, there are several main types of yamobur.

Hinged

This is a special equipment for drilling, the weight of which does not exceed 200 kg, and the length is 2 meters. This device is attached to all kinds of construction vehicles (excavator, tractor). Depending on the type of construction, drilling is carried out by means of a hydraulic or mechanical connection.

This type of equipment has a large torque and boom, with which you can drill the surface even in the most difficult-to-reach places. The telescopic hole auger is also attributed to the mounted ones, it is attached to the boom of the equipment. It can also act as an independent self-propelled drilling rig on a tracked or wheeled chassis.

This technique is used when drilling for supports or piles with a lower expansion.

Mounted pit drills based on MTZ (a tractor produced in Belarus with many modifications) are especially popular. Such equipment stands out for its small dimensions (width up to 8 m, length up to 1.9 m, weight up to 190-200 kg) and compact attachments. A drilling rig of this type is based on a KamAZ vehicle and is used to install piles into the foundation. They are produced only in small batches, as they are not the most common models. Such holes are also called all-terrain vehicles. It looks like a large and powerful tracked installation, which is used to drill holes for supports for bridges or other large-scale works. This technique, in addition to the auger, is additionally equipped with a device for screwing piles.

Another popular yamobur model is the manipulator. In terms of its functionality, it is much higher than conventional drilling equipment, since it is able not only to make a hole of the required diameter and depth, but also to install a pole or piles into the finished well. Very practical, folds up, allowing other equipment on the machine to continue working smoothly.

At the moment, there are already models in which such a manipulator is transformed into an aerial platform. Attachments are divided into hydraulic (usually connected to the hydraulic line) and gasoline (runs on unleaded gasoline).

Manual

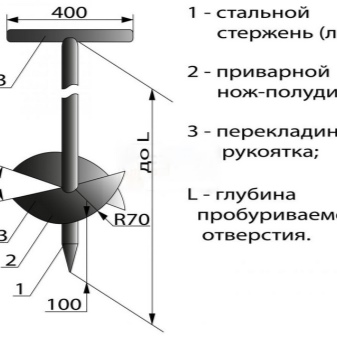

The simplest of them is the so-called manual yamobur. Basically, it is a screw-threaded rod (auger) that works like a drill. For to control and work it, you need to use physical strength. On its lower part there are edges that literally cut into the surface, and on top it is equipped with a specially shaped handle that allows not only to hold the instrument itself in an upright position, but also to make circular rotations. After the drill has gone to the desired depth, it is pulled out together with the ground, in this way clearing the hole from the soil.

Such mechanisms are used equally well both by professionals at facilities and simply for household purposes. They are convenient to use, they take up little space (which makes them easy to transport). Extremely easy to use.

Garden

It is the simplest model for drilling holes. Usually, looks like a steel pipe, at the end of which there is a screw tip, the top of the pipe has a T-shaped handle. It works through the applied physical force, it is most often used on garden plots. Manual models can work not only with the use of human power, there are also mechanical ones (powered by a petrol, hydro or electric drive).

Electric

This type of technique is not very popular. Such hole drills have an electric motor, which is located on the frame, and handles, so that it is convenient to hold and operate this device. For their operation, an additional three-phase power supply is required. With all the outward resemblance to the gasoline version, this model has a limitation in the radius of operation (you need to focus on the length of the cable).

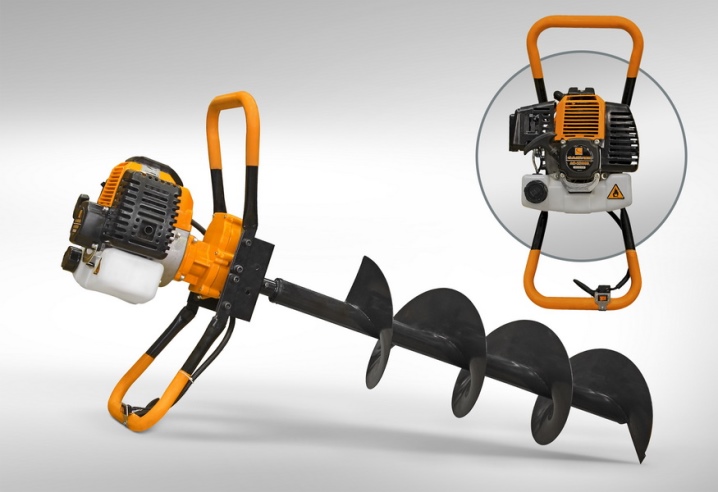

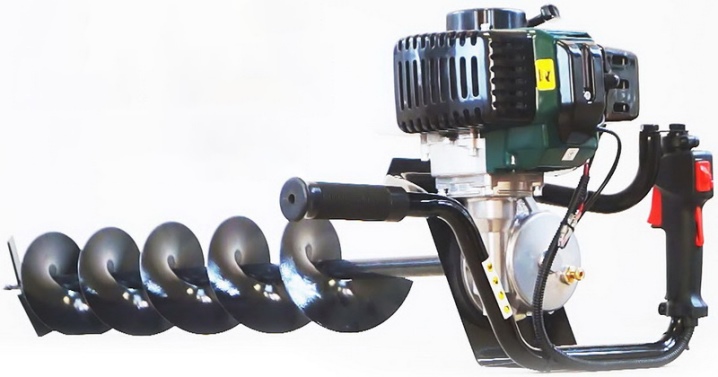

Gas drill

This device is able to solve a lot of tasks due to its high efficiency and relatively small size. But at the same time it will be difficult for one person to cope with such a technique, since the weight exceeds 20 kg, therefore, as a rule, two operators work at a time. The units are equipped with a gasoline engine, the power of which is up to 2.4 kW, and can make a hole up to 3 meters in diameter.

Hydrodrill

This type consists of a hydraulic station and a hydraulic motor on the control unit, they can be fastened together by means of a rod or separate. Thanks to the reverse, the drill can be easily removed from the ground and drilled in all directions. Drills earth, rubble, sand. It is capable of burrowing into the ground up to 4-5 meters, and when using an extension cord (this is an ordinary tube, suitable for the configuration, with which you can "add" the length), in general, up to 30 meters. It is possible to change the augers of the required diameter without additional tools. One person can easily cope with it, although the weight can reach from 30 to 60 kg. Easy to transform.

All drilling equipment is also classified according to the frequency of use. If you do not plan to use the installation on a daily basis, then many choose the so-called household models. The most common ones are made in China and are not of good quality. But with all this, they perform their functions well.

Semi-professional are considered to be of higher quality. They are significantly higher in price and are intended for occasional use.They can withstand heavy loads, stand out for better build quality. Large enterprises use professional drilling equipment that is designed for intensive work on a permanent basis.

As a rule, these expensive models are made of high quality materials. This type of equipment can be found in tool rental stores.

If the manual version can be used as much as necessary (in other words, until the person working on it fizzles out), then the rest of the models require cyclical work. On average, this is up to one minute of working condition, up to 10 seconds of idle speed. This indicator may vary depending on the drill itself and the soil on which the work is performed. So, on soils of the first category (loose earth, sand), continuous work is allowed up to 5 minutes, for the second (light clay, fine gravel) and third (dense loam, heavy clay) categories - up to 3 minutes maximum. If you do not adhere to the hourly interval, then this will certainly lead to damage to the gearbox.

And also experts recommend paying attention to the auger, which, in fact, is the main part of drilling equipment. It can be single-threaded and is a single-spiral tape, as well as double-threaded - these are two spiral ribbons that smoothly merge into special edges, which are located on opposite sides from each other. The two-way soil drill is the more popular model as it is more efficient in the process.

Another auger is selected for a certain type of soil. For example, the standard can only work on soils of normal density. Rocky ones are designed for working rocks, they are equipped with carbide teeth that literally crush the stone. And also augers are produced that work on frozen ground - they have removable carbide knives.

Based on these or those characteristics, everyone can decide on a technique for drilling soil. A wide selection will allow you to determine the desired model (from mini format versions to large units).

Popular manufacturers

Among the general abundance of this technique, experts single out several manufacturers whose products have been working trouble-free for years and deserve only praise. These are the best firms today.

The leaders include the manufacturer from the Netherlands Iron Angel. The company's specialists produce a huge number of options for drilling tools, which have an ideal price-quality ratio. For example, they have such models that have a powerful two-stroke engine, but at the same time they are very economical - the fuel is used in extremely small doses. They can be supplemented with a chrome-plated cylinder, and are also forcibly cooled with air, which will allow these units to work practically without pauses. Thanks to a special high-quality auger, they can be drilled into any kind of soil. The hole diameter reaches 30 cm, sometimes there is a replaceable 20 cm auger.

They are easy to assemble, the augers can be changed without the use of a key. The drill of this company is very easy to start even in severe frosts, since the fuel is pumped up by a primer (a special built-in pump). All necessary adjustments are located on the handles of the tool, which is very convenient to use.

Of course, the modification of the technique may differ from the above list, but the main popular options have this particular list of special features.

The honorable second place in the leaderboard, oddly enough, is Chinese firm Vulkan... It also manufactures many quality drilling tools. Manufacturers supplement their models with wide strong handles for ease of grip, the handles themselves are placed so that it is possible to work with a drill together. As a rule, augers are not included in the package, but they can be easily selected separately for any diameter.When changing augers, a wrench is also not required. Due to the air filter, the drill motor works great in dusty conditions. The equipment of this manufacturer does not experience any problems with starting in the cold by pumping fuel with a pump. Almost all models are capable of working on any kind of soil and penetrate to a depth of 80 cm.

Another noteworthy manufacturing company is Vitals. Latvian craftsmen produce compact, but very productive and safe models of pit augers. They are often chosen for landscaping and planting seedlings, because it is easy to make small narrow holes and large ones (up to 25 cm in diameter) with their auger. Almost all drills of this company do not exceed 10 kg in weight, they are very convenient for transportation. The auger can be changed without keys. Some types are equipped with an additional safety system that immediately turns off the engine in the event of a worm jam. Equipped with fuel pump. The handles are supplemented with rubber elements, which allows you to hold the instrument firmly in your hands.

The manufacturer has supplemented some drills with a system that dampens vibration, which makes it possible to work with the tool for a long time without feeling tired in the hands.

Anyone who has any idea of technology has heard about Maruyama at least once. This is a Japanese manufacturer. The technique of this giant is considered practically indestructible, which immediately entails a high cost of the tool. These models are assembled only on Japanese factory equipment, which automatically guarantees the long-term operation of the unit. Only high quality materials are used. The units stand out for their quietness. Withstand long hours of work. Economical. Robust reducer. The attachments are suitable for any size, due to the quick-release connection they change in a matter of seconds. Very compact, easy to fit in the trunk of a car.

The next country that produces the best drilling equipment is Slovenia. Sadko offers consumers a wide range of tools in this industry. The models from this manufacturer are not cheap, but they have a powerful engine. Easily work with frozen ground. Almost always equipped with a spiral auger with the most popular diameter size of 20 cm. They have small dimensions and weight.

How to choose?

When choosing a yamobur, experts recommend paying attention to several important points.

- If the drill is bought for the first time, and a beginner in earthworks will use it, then it is better not to dwell on a high-power unit. Unaccustomed and without appropriate experience, it will be very difficult to hold it in your hands.

- If you need a hand-held model, the ergonomics of the drill are important here. It is also worth studying the technical characteristics of the drill - in particular, the weight and design of the handle. It is advisable that the tool has soft rubberized pads that will not slide off during work.

- For many, a comfortable, wide neck of the gas tank is important.

- You can choose a model that is already equipped with augers of the required diameter. However, with the current abundance, it is not difficult to buy the necessary one. Over time, the augers become dull, and you need to choose those that are easy to sharpen. Some are guided not only by the diameter, but also by the length of the nozzle.

- When buying, for example, a motor-drill, you do not need to skimp on fuels and lubricants. This technique will only function well on quality motor materials.

- If you need to drill holes for pillars one-time, then experts still recommend not to spend money, but to resort to renting a tool. So you can quickly do all the necessary work with quality equipment.

As earthworks are gaining momentum every year, manufacturers regularly update and improve their models. At the moment, it will not be difficult to purchase a drill for a walk-behind tractor or for a hammer drill, it can be seen on the manipulator, on the tractor. It doesn't matter what size and power the unit is needed, now small models are being produced that are used on a mini-tractor, and overall ones, for example, for KamAZ.

How to use?

Such work requires careful preparation.

- First you need to understand that no communications will be damaged during drilling. Otherwise, it will lead to injury and financial loss.

- Study instructions.

- The next step is to inspect the tool itself: all parts must be intact, the wires (if any) are not exposed, there is no leakage anywhere. Check the durability, correctness and reliability of the auger installation.

- If possible, the face and body should be covered with a protective suit, mask or goggles.

- There should be no strangers on the territory where they work with drilling equipment.

- If during operation the drill gets stuck in a hole and does not give in, you should not pull it out by force - this can damage the tool itself and injure yourself. Better to help yourself with a shovel or crowbar.

- Many people carry out drilling under the foundation with the help of a hole drill. With it, the installation of screw piles takes very little time. And all this thanks to a special technique.

With the right drill model and careful handling, any job is done much faster and with minimal waste of time.

For tips on choosing a motorized drill, see the next video.

The comment was sent successfully.