How to make a drill for poles with your own hands?

The construction of houses and other structures often involves making holes in the ground into which pillars and other elements will be installed. It is not necessary to use state-of-the-art drilling technology to make these holes. An ordinary hand drill can also be quite effective. We will talk about the methods of making it in this article.

Required tools and materials

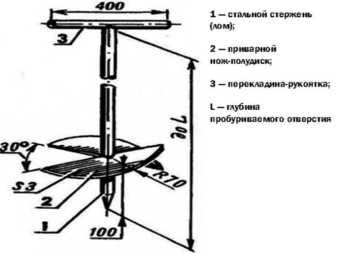

Making a handheld ground drill to install the poles does not require significant effort. To create an item, you will need the following:

- nuts and bolts in size M20;

- two steel discs with a diameter of 100-150 mm;

- drill made of high speed steel for a hole diameter of 2 cm;

- steel pipe with a diameter of 4 cm and a wall thickness of up to 3 mm (lengths of 50 and 40 cm).

The pipe must withstand a significant load when drilling even clayey soil, which is more dense than chernozem or sandy loam that lies between clay layers. Ready-made circular saw models are suitable as discs. Self-made discs are made of sheet steel with a thickness of at least 3 mm (like the pipe walls).

The toolkit is represented by the following devices:

- hammer;

- grinder with a set of cutting discs for metal;

- welding machine and electrodes with a metal pin diameter of 3.2 or 3.5 mm;

- a drill (or a hammer drill in drill mode with an adapter for drills for metal) and a set of HSS drills;

- tool for sharpening blades and knives.

Bicycle handlebar grips will work as a soft handle for the future drill.

Manufacturing of parts

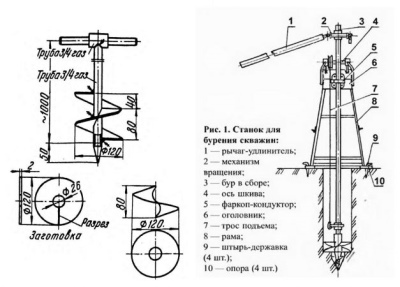

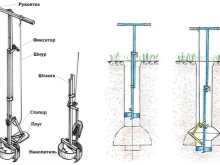

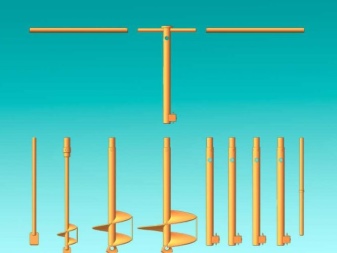

First, decide which drill you need for the job. A simple garden drill consists of separate half-plates set opposite each other. Together they form one complete turn, without which it would be problematic to drill the ground. The main task of such a tool is to dig holes for bush seedlings and even seedlings. With a garden drill it is possible to drill holes for a concrete support (round and professional pipe, thick reinforcement, etc.). The screw apparatus consists of several continuous turns wound from a strip of sheet steel. It is more difficult to manufacture, because it is impossible to achieve a perfectly flat auger (screw) without a lathe or milling machine.

When performing work, use a ready-made drawing or create your own. The future instrument is made on it. Next, you need to follow the instructions below.

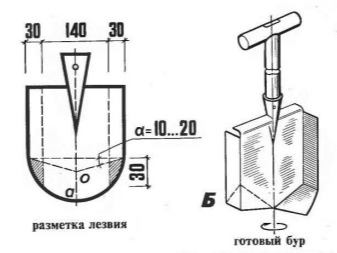

- Draw a circle on a sheet of steel using a compass and mark the center. The round part cut off from the sheet is the future blade. Cut it out using a grinder.

- Draw, using the center of the circle you just cut, an internal cut through which the sawn disc slides over the knob. The outer diameter of the wrench tube must match the inner diameter of the cut hole. Cut this hole in the disc.

- Cut the resulting disc into two pieces.

- Cut four longitudinal lines (an average of 3.5 cm each) at the end of the wrench. Using a hammer, bend the resulting pieces so that their ends meet at one point. You will end up with a tip that will set the direction for drilling every time the drill goes into action.

Boil the formed seams. Ensure that the drive is resistant to soil filling.

To connect the wrench to the disc, do the following:

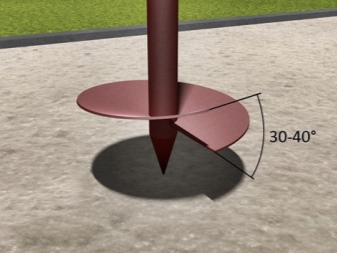

- attach the knob to the disk and ensure that the angle relative to the drilling plane does not exceed 20 degrees;

- maintain a distance of 5 cm between the parts of the disc, apply marks on the knob that set the view of the future structure;

- by welding, weld the parts of the discs to the wrench.

To lengthen the wrench, the steps below are required.

- Weld the second pipe to the axle tube, behind which the drill is manually rotated. The structure will be T-shaped. For structural strength (so that the handle does not bend), weld reinforcing triangular spacers, which are used as reinforcement pieces.

- Slide the T-piece into the knob and secure it with a piece of hairpin. There can be several attachment points.

After completing the assembly of the wrench, sharpen the blades using a grinder or a sharpener. The cutting edge must point downward.

Looseners

The openers help the worker to position and maintain the upright position of the drill. For them, you need a piece of sheet steel with an average size of 250x35x4 mm. The pre-loosener will have an average length of 12.5 cm.

Step-by-step manufacturing instructions:

- position the workpiece on one side at an angle of 10 degrees;

- attach the second side to the main axis of the drill;

- make sure the direction of the tape matches the direction of rotation of the drill;

- cut the end of the tape at an angle of 30 degrees and sharpen it, giving it an oval shape;

- With the pre-ripper installed, weld the cutting blades cut from the halves of the circular saw to the drill shaft.

The spiral formed in this way should run at a certain angle - like a helical groove on a large bolt. The sides of the parts of the resulting spiral are bent in opposite directions. One of the cutting edges plays the role of a soil pick-up device, the second - a pusher.

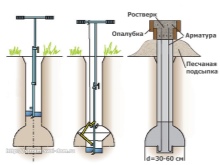

Threading

When the drill is to be used as a tool for digging wells in personal plots, it is better to make the pipe multi-section. Groundwater often flows at a depth of 30 m, so the sections are made for a specific depth, and each of them should not be longer than a meter. Longer sections will be difficult to install alone. A threaded sleeve is used as a joint. Each section has a thread and is equipped with a cotter pin, so that the sudden unscrewing of the pipe during movement is excluded.

A pen

Without the handle, rotation of the drill would be impossible. The handle is made of pipes or solid reinforcement that can withstand a significant load when drilling rocky soil. Most often, handles are made of rolled ferrous metal. Such a handle is devoid of a springy effect, it transfers the twisting force of the working part of the drill. The end opposite to the working part of the drill is connected to the handle of the device by welding.

The longer the handle, the more comfortable it is to work with the drill, but this does not mean that the handle should be longer than 50 cm. The fact is that a too wide and long handle will force the worker to stay as far from the drill as possible, which will not make the work efficient enough. The pipe diameter for it is at least half an inch, the wall thickness is 3 mm.

Additional links

At the end of the main assembly, the cutting edges are sharpened at an angle of 60 degrees, and additional notches take up no more than 3 mm. A small drill is welded to the tip, which sets the direction of drilling. If the drill is made without a handle and is intended for a walk-behind tractor or an electric drive (mechanized drilling), the nozzle is subject to accelerated wear.

You can do without a drill, replacing it with an elongated tip cut and welded according to the instructions above. But such a tip enters the clay soil or compacted, weighted chernozem worse, and also contributes to the drift of the drill axis away from the vertical position.

The simplest replacement for a classic drill will be a peak one: it is a symmetrically bent plate with a sharp point, pushing apart the ground no worse than a perfectly round groove bayonet in cross section.

Between the drilling point, which sets the correct direction for drilling, and the main plates, additional plates are installed - two or more times smaller. It is easier to cut the soil with such a drill. First, at a short distance, a channel narrower in diameter is made. Drilling it to the final diameter is much easier and faster than punching the latter from scratch. This feature is good when there is no mechanized installation, and you have to drill dense layers of clay and loam, getting to the aquifers of the future well.

Final assembly

A deep drill before drilling wells is collected gradually, plunging deeper into the underlying layers of the soil. Before further drilling, the foreman will check whether the next section is securely fixed: if it is accidentally unscrewed, it will be extremely difficult to get it (and other sections, including the drilling section) without special devices from an already drilled shaft. Disassemble the drill in the reverse order, taking care not to drop the unassembled part to the bottom of the channel.

Each of the extension sections (pipes) is welded to its sleeve on one side of the latter: this will facilitate and simplify assembly, and reduce the likelihood of unscrewing during deep drilling. Before the first use, the drill is sanded: the formed irregularities, for example, after welding, are removed in order to reduce injuries.

Protective coating

After stripping and grinding, the finished product is coated with paint. If the pipes and plates from which the product is made are not new, the best result will be given by a rust enamel primer. The appearance of rust on the handle-crossbar is excluded when work is performed daily, since the handle is often and for a long time in the hands of the worker. Coating will significantly extend the life of the product, but is not always necessary. With frequent friction against the ground, the protective coating from the cutting inserts is erased, and it does not make sense to apply it. It is needed only in those situations when the drill is rarely used, stored in conditions of high humidity and sudden changes in temperature.

Helpful hints

Consider some useful tips for those planning to drill in their area.

- Drilling the ground alone and without a walk-behind tractor (electric drive) is not an easy job. Use a drill with additional sections, because a constantly bent back will not add to the worker's health.

- If, while drilling, a master stumbles upon, for example, a rock, you should abandon home-made and hand-held drills and use the services of a custom-made (mobile) drilling rig equipped with a high-power walk-behind tractor and using methods of vibrational drilling of rocks and rocks.

- As a finished drill, it is recommended to use a concrete drill with a diameter of 12-20 mm. It is welded to the tip. Do not use a drill that is too long: this will noticeably weigh the structure.

- Maintain verticality while drilling. A significant bevel and sideways movement, for example, of a fence post hole or any other post construction, may not allow the same post to be concreted. Either that, due to the shifted center of mass, over time, it tilts to the side.

- The cutting ground loop, assembled from two halves, is easier for excavation than a solid one made from a solid strip of sheet steel or a circle.

- Do not drill too far into the depths: even with a hoist, pulling out an overly large and heavy layer of earth is problematic. Sheet steel can bend under significant soil weight. In this case, the drill must be aligned: it must always be symmetrical.

How to make a drill for poles with your own hands, see the video below.

The comment was sent successfully.