What are skimmers and how to use them?

To keep the water in the pools clean, various modern equipment is now used. And the list of the most effective devices includes skimmers. In this case, we are talking about a rational, practical and, most importantly, the most affordable solution that allows you to quickly get rid of garbage of different sizes.

By and large, such a device is a kind of tandem of coarse and fine filters. But it will not be superfluous to find out what modern skimmers are and how they should be used correctly.

What it is?

Unfortunately, particles of dust, leaves, algae and objects of artificial origin constantly appear in the pools, both on the surface and often in the water column. They come in completely different sizes, from microscopic to visible to the naked eye. In the fight against them, a skimmer effectively helps, which is filtering device. It looks like a fairly compact container, combined with a branch pipe, inside which there are water intake holes, as well as nets that prevent clogging of the system.

It is worth noting that in some cases the skimmer itself acts as an obstacle on the way of large debris into the pipeline.

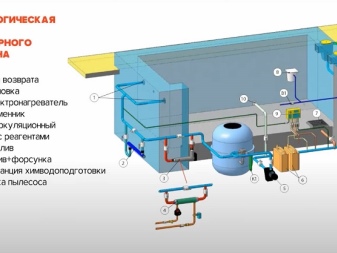

In the classical version, the principle of operation of the described device is as follows.

- Through special holes in the body, water enters the container.

- Due to the presence of a special separating element, only one upper layer, that is, a contaminated layer, appears in the system.

- The largest samples of debris are caught by a net installed almost at the very beginning.

- The filter element retains suspended particles.

- The stream purified in this way is directed to the disinfecting part of the system.

- If there is such a need, water passes through a special thermoblock and is fed back to the tank.

It is noteworthy that modern models of the equipment in question, presented on the market by leading manufacturers of the industry, are capable of performing the functions of not only a cleaning and disinfection module. This list also includes:

- integration of a water vacuum cleaner;

- control and regulation of the level of the pool mirror;

- maintaining the set water temperature;

- adding reagents.

In order to fully understand exactly how such units function and what exactly they are needed for in modern pools, it is necessary to pay attention to their design. In the standard version, such a device consists of the following elements:

- intake nozzle;

- net in the form of a basket for large debris;

- pumping unit;

- control system;

- drain.

One of the defining characteristics of a skimmer, which should be taken into account when choosing a device, is the design power. It, in turn, is determined by the volume and dimensions of the reservoir itself.

Views

Today there is a fairly wide range of systems designed for cleaning not only swimming pools. Also on the market are aquarium devices and equipment focused on the fight against pollution of ponds and other bodies of water. For example, an oleophilic skimmer and a special vacuum-type skimmer system are successfully used for surface collection of oil.

If we are talking specifically about structures for pools, then it is also worth focusing on the variety of systems. So, there are universal models with refill (auto refill) and overflow in the form of special chambers and gutters. But at the same time, the varieties of skimmers available for sale are classified mainly according to three main parameters:

- installation method;

- material of manufacture;

- the size.

In order to fully understand what it is, how the described device for cleaning the water surface works, looks and works, it is necessary to pay attention to the key features of its modifications. In this context, the following types can be distinguished:

- built-in;

- hinged;

- floating.

All of these varieties are predictably different from each other in appearance, design and principle of operation.

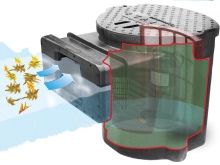

Embedded

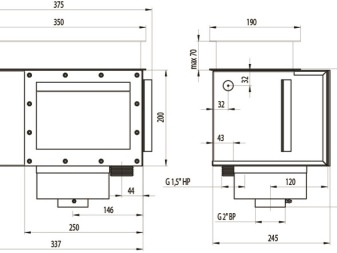

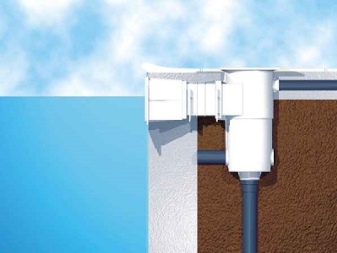

This stationary version of the systems under consideration is integrated into the body of the pool. It is important to note that such a skimmer can be installed only at the stage of tank construction and this can be done in one of the following ways:

- under the tiles;

- in a monolith;

- under the film.

Another key point is that the dimensions (length) of the filter element must correspond to the thickness of the walls of the pool. But in practice, it is far from always possible to choose a model, and then nozzles come to the rescue.

Installation of the recessed skimmer is simple and easy to do following the manufacturer's instructions. However, despite the simplicity of the installation process, it is highly recommended to keep the following key rules in mind.

- Only those fasteners, special brackets and other accessories that are supplied with the device should be used.

- Before direct installation of the skimmer, the opening in the tank wall must be leveled as much as possible, adjusted in size and thoroughly cleaned.

- The device must be placed strictly horizontally.

- The structure covering the unit can be increased in height by no more than two rings.

It is also worth noting that when installing integrated skimmers in outdoor pools, it is extremely important to consider the wind rose. This will eliminate the formation of stagnation zones.

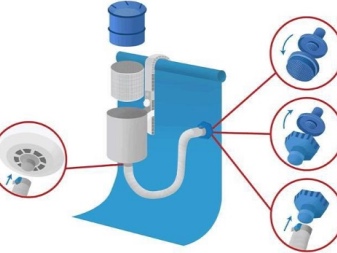

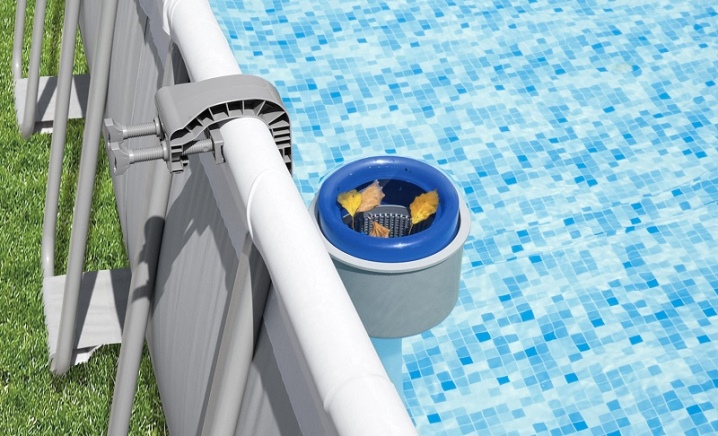

Hinged

Such filtering systems are versatile, since they can be equally successfully used for water purification in prefabricated and stationary pools. But it is important to remember that these must be reservoirs without water renewal. Another important feature is that the hinged skimmer is able to work in two directions due to the built-in reverse acting water pipe.

The bodies of such devices are made of durable plastic. For installation on the side of the pool, special brackets are provided with adjustment. It is these design features that determine the functionality and scope of the suspended models of the equipment under consideration. They will be the optimal solution when equipping a stationary bowl, if during its design and construction, for one reason or another, an opening for the built-in filter element was not provided.

Floating

This type of skimmer can be confidently described as the simplest in terms of design, installation and use. However, floating models are the least effective. They will be relevant in pools, which are characterized by a constant change in water level. These include frame and inflatable options.

The main features are the presence of a sensor and special fasteners. Thanks to them, the filter is automatically adjusted taking into account the level of the pool mirror. In most cases, such purification devices are capable of processing from 20 to 45 cubic meters of water.

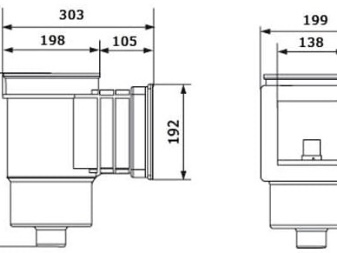

Device materials and dimensions

As already noted, devices for surface water purification are classified, including taking into account the materials from which they are made. At the moment, manufacturers are using:

- stainless steel for the manufacture of integrated skimmers, which are quite expensive;

- plastic, as a rule, we are talking about PVC, ABS-plastic and polypropylene, which are distinguished by good strength, practicality and, most importantly, availability;

- bronze is a material for the manufacture of built-in models of equipment belonging to the premium segment, the main advantage is a long service life, and the disadvantage is the high price.

If we talk about the size, then it is worth noting that this parameter determines the throughput of the equipment. It is clear that a narrow tubular assembly will have corresponding characteristics.

In practice, this very ability most often varies in the range from 2 to 7.5 cubic meters. m / h. Systems with increased performance are able to remove debris up to 25 "squares" of the water surface.

Spare parts and components

The described devices have the most simple design, the elements of which rarely fail and require replacement. But, unfortunately, even the most reliable equipment and products are not insured against breakdowns. So, in the process of intensive operation of the skimmer, you may need:

- floating curtain;

- basket-net;

- decorative overlay;

- pipe branch;

- pump hose (pump).

In addition to all of the above, of course, do not forget about the need for maintenance and periodic replacement of filter elements.

Top manufacturers

Taking into account the efficiency and popularity of skimmers, now in the corresponding market segment, a whole model series of such equipment is offered by many eminent manufacturers. Taking into account the statistics and reviews, we can single out the clear leaders.

- Kripsol – a company representing Spain and occupying for 3 decades a leading position among manufacturers of high-quality equipment for swimming pools. Built-in models of skimmers of this brand are distinguished by their reliability and longevity at an affordable price.

- Emaux - a manufacturer from the Middle Kingdom, specializing in pool water purification systems. The brand has become famous mainly for its built-in skimmers. According to users and experts, in this case we are talking about a good ratio of cost and quality.

- FitStar Is a German brand of the renowned company Hugo Lahme GmbH, whose history began back in 1945. On the market, the manufacturer presents cleaning systems for stationary pools. These products are of the premium class and are most often made of high quality stainless steel or bronze.

- Intex Is a world famous American brand. The company specializes in the production of inflatable pools and equipment for them. The list of the latter includes, in particular, suspended (overhead) skimmers, which, due to their affordable prices and high quality, are among the most popular at the moment.

- BestWay - the company, the creation of which was the result of cooperation between American and Chinese specialists. Specializes in the development and production of inflatable pools and a wide range of related equipment. Surface skimmers of this brand are in high demand and quite successfully compete with similar Intex products.

- MTN Is another German manufacturer whose pool cleaning systems have won their place in the market for efficiency, as well as ease of use and maintenance. For example, attachments are equipped with both a basket and an additional fine filter.

Selection Tips

First of all, it is necessary to emphasize that the selection of this equipment directly depends on the characteristics of the pool itself. The only exception will be universal floating devices. If we are talking about frame and inflatable versions of tanks, then only hinged skimmers are relevant for them, when choosing which it is recommended to consider the following important points.

- Unit performance, determined by the size of the pool.

- Width of the clamping part of the bracket, selected depending on the thickness of the walls of the bowl. This parameter is most relevant for inflatable pools.

- Tightness of the whole structure... This means, first of all, the presence of high-quality O-rings between the container, filter and float, preventing dirty water and debris particles from entering the bowl.

- The presence and quality of the internal fine filter. It should be noted that not all models of suspended skimmers are equipped with such an element. At the same time, its presence in the system will be desirable, especially for pools in which water changes are rarely made.

If, during the construction of a stationary pool, the described cleaning device was not installed as an embedded part, then an overhead device will have to be selected for it. In this case, one should be guided by the above criteria. When it comes to building a bowl, then the only correct solution would be to choose a built-in model, taking into account the following parameters:

- bead thickness;

- the material of the device, which directly determines its service life (models made of stainless steel and bronze are practically eternal, their plastic counterparts last about 10 years);

- features of the tank finish, on which the design features of the skimmer depend;

- system functionality (level adjustment and water heating, reagent addition);

- equipment.

In addition to all that has already been listed, of course, one should not forget about such an important characteristic as the performance of equipment. In particular, we are talking about the matching of the skimmer throughput to the performance of the circulation system.

How to do it yourself?

With the appropriate tools and skills, you can quickly make your own external skimmer from sewer pipes. This will require:

- PVC pipes with a diameter of 32, 50 and 110 mm - 400, 550 and 550 mm, respectively;

- connecting sleeve with a diameter of 110 mm;

- tee 100x110x55 mm;

- plug with a diameter of 110 mm - 2 pcs.;

- eccentric adapter 110x50 mm;

- adapter sleeve 50x32 mm;

- metal-plastic tube with standard thread.

The procedure for assembling a homemade pool cleaning unit will be as follows.

- In the center of the plug, make a hole no more than 52 mm in diameter under the rubber adapter.

- Assemble the bottom of the future skimmer system... It will be necessary to insert a connecting sleeve into the tee, and close the opposite side with a second plug. A transition sleeve should be placed in the side outlet.

- A float is made. It will be required to cut a circle from the foam, the outer diameter of which should be slightly less than the diameter of the main pipe, that is, 110 mm, which will ensure the smooth sliding of the part. The inner diameter of the float is 50 mm.

- The finished float is put on a pipe of the corresponding diameter... This structural element is fixed approximately 2 cm above the center.

The main feature of such a homemade device is its fairly low weight. With this in mind, the structure will float predictably in the pool. It is possible to eliminate such risks by placing a load at the bottom of the manufactured cleaning device, which will prevent its movement in the water. After the weighting agent takes its place, continue the assembly according to the following scheme.

- A thin tube is inserted into the bottom of the 110mm pipe with a float attached to it.

- Additional threads are cut on the upper plug. This modification is necessary in order to then be able to install the metal tube, which is necessary for the rarefaction of air in the system when sucking in water.It is important to remember that the liquid inside the unit must move upward, above the level of the mirror in the pool, so that air can escape.

- A hose is placed in the lower splitter, on the other end of which you will need to put on an adapter.

At the final stage, it remains to connect the assembled device with the filter pump. If necessary, a heating circuit can also be included in this circuit.

How to use it correctly?

Naturally, the features of the operation of the equipment in question directly depend on its type. In cases, for example, with mini-devices or a skimmer for a marine aquarium, certain nuances will take place. But in standard cases, first of all, you need to pay attention to the installation of devices. If it is necessary to use a mounted model, the procedure will be as follows.

- Assembling the system according to the manufacturer's instructions... It is required to place a mesh basket, a sealing element (ring) and a funnel float in the container. An exception would be a homemade cleaning unit.

- Fixing the skimmer on the side of the bowl using a bracket and clamps, functioning as a clamp... In the presence of fasteners in the form of ordinary hooks, the device is simply hung on the pool.

- Hose connection to fine filtration and circulation systems.

Installation of built-in equipment will be determined by the type of tank itself. Installation during the construction of a concrete pool includes the following steps.

- The box is made in accordance with the dimensions of the device.

- The product is installed in the formwork and fixed.

- Concrete mix is poured.

- After the concrete has completely solidified, the skimmer is inserted into the resulting opening.

- The unit is fixed with dowel-nails with the obligatory installation of rubber seals.

In situations where an acrylic stationary bowl is equipped, an opening is cut out in it according to the previously made markings. In this case, the fixation of the device is carried out using special self-tapping screws.

It is no secret that the efficiency and durability of any equipment directly depend on the correct operation of it, as well as timely and competent maintenance. In this context, the key procedures boil down to the following actions:

- regular cleaning of the mesh basket according to the manufacturer's recommendations and the corresponding instructions for a particular model;

- periodic removal of plaque, which inevitably forms both on the inside and on the outside of the body.

It is important to take into account that the frequency of any preventive measures will depend on the intensity of the use of the pool itself. An equally significant circumstance here is the presence of external factors. But in any case, the recommended interval should not exceed 3 weeks.

The comment was sent successfully.