What is the power of an LED strip and how to determine it?

The power of the LED strip is the second parameter after the nominal voltage that consumers pay attention to. After it, the suitability of the tape for a certain weather or microclimate is checked, and other parameters.

What does it depend on?

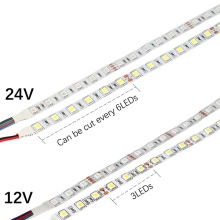

The power of an LED strip depends on two characteristics - the operating supply voltage and the current consumed by each LED. The power is equal to the product of the LED voltage by the amperage (amperage). The current strength with a series connection of LEDs (in assemblies for 12, 24, 220 volts) is the same - it depends on the characteristics of a particular light element, of which (completely identical) the light tape is assembled.

It is not recommended to assemble LEDs of different power into one assembly - low-power LEDs glow brighter, larger ones - much dimmer. If there is a driver in the luminaire, in which it is stabilized by the current strength for LEDs of lower power, then the luminaire will not shine, or the glow will be pixelated, fragmentary, depending on the power of each LED. In the case of connecting a long tape with different (not the same) LEDs to a source of a voltage higher than several volts, the low-power LEDs will burn out, and after them, if a thermal breakdown occurs, and the LED has become an ordinary conductor, the rest will burn.

Despite the fact that even LEDs of the same batch differ slightly in voltage (within hundredths of a volt), a slight "discrepancy" may result.

This feature is not critical - some LEDs shine slightly weaker, in a lamp or light bulb with a matte diffuser, this small difference is invisible.

How to calculate the power?

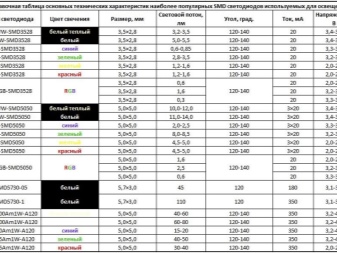

For power calculation there is a table of nominal voltage and current consumption values. According to it, LEDs of different ratings have different current consumption from each other. For example, light elements similar to ordinary LEDs produced in the USSR, which, in turn, were installed in the display panel of long-distance telephone equipment (radio relay equipment), differ in a current consumption of 15-30 milliamperes with a voltage spread of 2.7-3.2 volts ... In no case should you exceed these parameters - ideally, the LED should almost not heat up at all. Heating is allowed to a temperature not higher than that of a healthy person's body (not warmer than a finger). Always remember that an LED is not a gas-discharge or an incandescent lamp; it should generate almost no heat. If you apply a voltage of 3.4-3.8 V to such an LED, then the heating will become more significant - up to a temperature of 50-55 degrees, and a voltage of more than 4 volts will completely lead to its accelerated degradation (the LED will heat up to 70 degrees, after which it simply sags - "breaks through" by heat and becomes unusable).

1 meter

Let's give an example. A 220-volt tape, working in long sections on SMD LEDs, has 60 pieces per section. Of course, if you count on the characteristics, without overloading, in the case of self-collection, 80 of the individual LEDs ordered by the party in China would come out. Here the calculation is that the tape will work at least the declared 25 thousand hours, and not "interrupt" somewhere between 2000 and 3000 hours of real work, as is often the case as a result of deliberate going beyond the operating parameters.

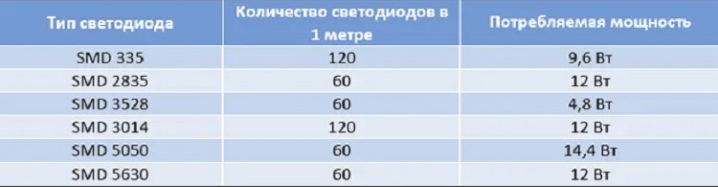

So, SMD-5050 has a power of 0.1 watt. 60 pieces - already 6 watts. The luminous flux of a 1 meter long tape is 480 lumens (8 lm per LED).You can find out the current consumption "from the outlet" by dividing 6 W by 220 V. As a result, we get 27 mA consumed from the network. In reality, some losses (up to 5%) are due to the diode bridge - it heats up slightly, so in fact the tape consumes 30 mA of alternating current at 220 V. And if we take (as is often the case) the heat dissipation of overloaded LEDs, then another 40-50 percent will go to heat. As an example - LED bulbs, the base of which even burns the hand (70 degrees, +50 to room temperature, in the form of heat), then the heat loss of the LEDs and the rectifier (or driver) results in 60% or more. As a result, instead of 30 mA at 220 volts, the entire assembly will take 50 milliamperes.

In terms of power, with a light of 6 W, the actual (total) consumption of a light strip with a rectifier can result in 10-15 W.

Full length of tape

Let's take as an example all the same LEDs - SMD-5050. Per meter (60 pcs.), Their light flux is estimated at 6 W, with a consumption of 10-15 (the remaining watts, as previously mentioned, go to heat due to an incorrect calculation). If such a tape shines at 6 W per meter, then for the entire length, suppose, of the corridor (100 meters, the first floor of a factory or plant, the transition between workshops), the tape will give out 600 W of light. In this case, the consumption will be the same as that of a single-burner electric stove or an oil-filled electric radiator - kilowatts or more. Tapes powered from 220 V are often switched on through an automatic fuse on the "phase" wire of the line - its operating current is equal to several amperes. If the luminosity of the tape changes from a voltage surge in a large direction, this automatic fuse will "shoot", open the line, and the tape will be de-energized.

For example, 5 hundred-meter strips of such LEDs can be turned on through a standard 25 A difavtomat used in apartments and country houses.

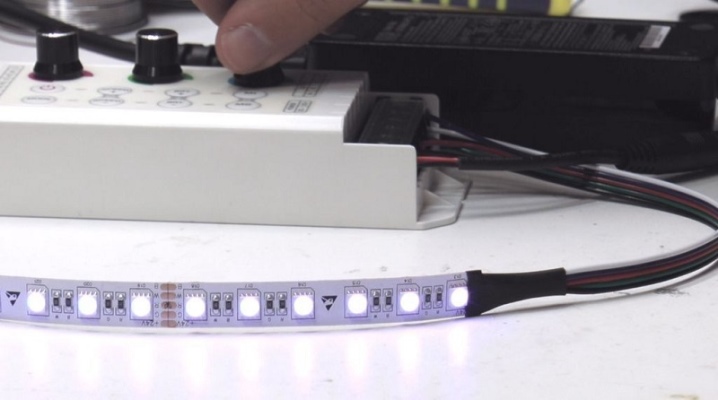

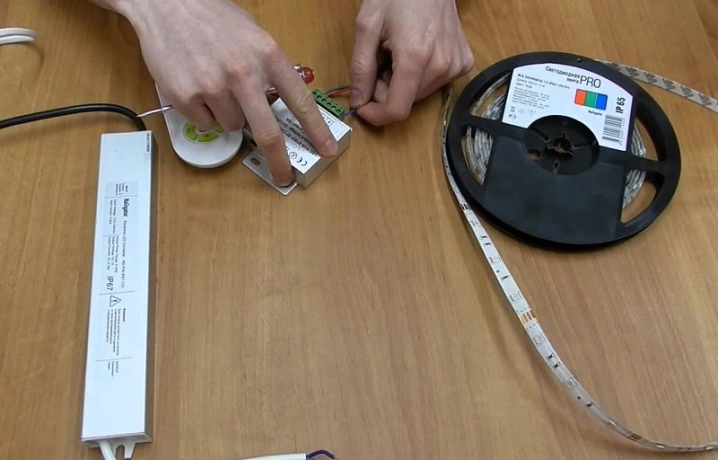

Calculation of the converter

If 220 V light-tape lighting requires nothing but a rectifier with a filter (capacitor) for the same voltage, then 5-, 12- and 24-volt mini-assemblies need an additional converter. As the latter, a current driver or a stabilized power supply for the same low voltage is used, calculated with a small margin in order to avoid power sagging.

The simplest example is a driver in standard E-27 basement light bulbs. A 3W light bulb contains 5-6 LEDs soldered into a circular board with an aluminum backing. The latter is used as dissipating heat. Practical advice from home-builders who repaired such bulbs boils down to increasing the resistance of one of the resistors in the circuit so that the driver hardly heats up.

For example, instead of the minimum 18 ohms, you need to put a resistor at 40. Soldering additional LEDs of the same type into the gap of the light assembly does not give the result: the driver has a "power reserve". His microcircuit will still go into "overkill", since the current is set, which is taken with a margin. Such a light bulb really shines at 3-5 W, but it consumes at least the same amount of energy for excess heat. The 3-watt bulbs use 5-6 dual LEDs (connected in pairs with an internal series connection, double crystals), each of which consumes at a rate of 6 V. In practice, the manufacturer, in order for the lamp to glow as brightly as possible, assigns all 8 volts to one double crystal. Five such crystals are 40 volts, 6 - 48.

If a light bulb is designed for 10 crystals, and it indicates that its power is 5 W, then the driver generates a direct current with a voltage of 80 volts - normally it should give only 60. Another 5-10 W are dissipated for unnecessary overheating. The technology for calculating the converter is violated, and soon after the purchase it will burn out along with one or more LEDs. To prevent this from happening, home craftsmen, by changing the limiting resistor that control the current of the microcircuit, achieve normal operation. At the same time, the light bulb shines not by 3 (or 5) watts, but by 2-2.5 (3-4), its brightness decreases by half.The fact is that even in the non-overloaded mode, losses of 5-32% for the small heat generated by the driver (depending on the complexity of the circuit and the quality of electronic components) are preserved.

Conclusion: when calculating the converter, it must not be allowed to overheat. If the power of a 1 m tape is 6 watts, use a power supply or driver with a power reserve of 2-3 times. In this example, its power (maximum, not peak) is 12-18 watts. Rounding off this figure, invest in a 20-watt power adapter.

Both he and your light tape will work without problems for 10 years or more.

How to calculate consumption?

A practical example is to try to measure the need for light using already purchased basement type LED bulbs. If, say, 3 ten-watt bulbs (into a large chandelier) are required for the kitchen-living room of a country house, then start from this value. Your task is to calculate how long the wall (or ceiling) tape running along the perimeter of the room will be needed.

As an example - all the same light strips on light elements SMD-5050. One meter is six watts. To create a flux of such power, take 5 m of such a tape. It is released by meter - in a reel along the total length indicated on the package. It will pass along one of the walls, for example, above the sofa and the door, from the side of one of the longer, opposite walls. Both three bulbs and five meters of light tape ideally consume 30 watts per hour of continuous operation. You can check whether the real parameters correspond to the declared ones by comparing the output of LEDs of different brands.

If you don't want to bother with detailed calculations, then get an idea of the similar output power of LED bulbs - and calculate how many meters of tape you need.

The comment was sent successfully.