All about power supplies for LED strip

Interior LED lighting is a beautiful and original design solution. LED strips are especially popular in the design of stretch and suspended ceilings, wall niches, furniture shelves or paintings. LED strips are also often used to illuminate work surfaces, for example, in the kitchen or bathroom. Devices can be single-color or multi-color. For the LEDs to work, it is necessary to supply them with power using the unit.

What it is?

Power supplies are current transformers. The light strips themselves are sold separately and are not directly connected to the network. An alternating current of 220 volts comes from the outlet, and the power supply converts it to direct current. The power depends on the needs and the type of the tape itself. Indicators range from 12 to 220 V.

The adapter protects the structure from voltage surges, supplies power, and also allows you to control brightness and color using additional accessories.

Species overview

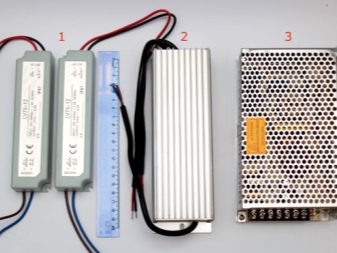

Depending on the purpose and mounting location of the backlight, you may need different power supplies for the LED strip. The principle of operation of the device can be pulsed, linear and transformerless. Linear blocks appeared earlier than anyone else and therefore are the most reliable, but also cumbersome. The transformer reduces the power to the required one, the rectifier converts the voltage into a constant voltage, the stabilizer ensures that there are no drops.

Pulse systems have replaced linear ones, their efficiency is much higher, and their dimensions are more compact. The pulse generator generates a voltage with a frequency much higher than the usual 50 hertz, so there is practically no noise or hum from the pulse adapters. The pulse transformer is newer and more perfect than conventional ones, which explains the small size. Such blocks are the most popular and budgetary ones. They can be thin and tiny, especially if you need to feed a not too long strip of tape.

The transformerless type of device is very rarely used to power LEDs. Their scheme of action consists in sequentially lowering the voltage to the required one with stabilization at the output. Therefore, this view is the most unreliable. The power supply should not be confused with the driver. LEDs are powered by current and are semiconductors with a certain resistance. In short, each individual LED in the circuit “eats” a certain amount of volts. So the next one gets the nourishment below.

To stabilize the situation, the drivers are installed. They work in tandem with power supplies, controlling the power and preventing the LED elements from burning out. You should not connect the tape directly through the driver, their tasks are different from the purpose of the power supplies, and the design will not be durable.

The ultra-thin driver will not take up too much space, but will improve the performance and reliability of the backlight.

By cooling system

There are two options for cooling the system: active and passive. In the first case, a fan is installed in the transformer, in the second, the structure as a whole looks like a regular computer unit and releases heat through the case. Active cooling is preferable for a backlight that will work for a long time or even permanently. An example is the decoration of shop windows, windows, interior lighting in rooms.

But the motor will hum - if there are no other sound sources in the room, the noise will be annoying. Units with passive cooling are suitable for domestic use with intermittent switching, for example, for illuminating work surfaces.

By execution

There are blocks of varying degrees of openness. Non-hermetic transformers have a perforated casing, which allows the elements to cool naturally. The design of the printed circuit board has quite impressive dimensions, so you should think in advance about the place for installation. In addition, it is not recommended to mount such blocks inside the walls or cover with decorative panels due to the likelihood of overheating. Dust settles on such mechanisms faster. But the parts used are simple and unpretentious - there are many models on the market with an output power in the range from 6 to 400 watts. Leaky structures are cheaper than analogs and rarely break.

Semi-hermetic power supplies are protected from outside by a plastic case from foreign objects and dirt. They are smaller than the previous ones and have an output power of 60 watts, because it is impractical to produce blocks of lower performance. AC adapters are also a type of semi-sealed power supply equipped with a plug for direct connection to an outlet. They look the same as ordinary chargers, are very tiny and, due to their size, are capable of supporting a voltage no higher than 24 W. Sealed blocks are much better protected from any environmental influences. They do not differ in size from semi-hermetic ones; depending on the voltage, they can have two versions of the case. Low-power models are packed in plastic, and high-power ones in an aluminum casing.

Any industrial product is marked with a degree of protection. You can find it by the abbreviation IP with two digits after. The set of numbers ranges from IP 00 (no protection) to IP 68 (completely protected from dust and moisture). The first number denotes resistance to pollution - from zero to six, the second - moisture permeability, from zero to eight. That is, the marking should be read from left to right: for example, IP 12 means low protection against dirt (1), and level of protection against moisture 2. For power supplies for LED strips, most often you will find three variations:

- IP 20 - the system has an open casing with large perforations, is protected from the ingress of large objects, has no protection from moisture;

- IP 54 - the transformer is partially sealed, it is not afraid of splashes of water and the ingress of any particles, the degree of dust is extremely low;

- IP 67 or 68 - the sealed housing fully protects the elements from any impact, up to full immersion in water, it can be used in swimming pools, outdoors, in wet rooms, showers.

If you need to power a very short tape, you can choose a battery-powered power supply. Of course, it will be low-power and short-lived, but if we are talking about decorative festive lighting, then this option can save the day. Especially if it is intended to illuminate a mobile structure.

Battery powered is used for portable lights, souvenirs, figurines, wall panels or paintings.

By functionality

The simplest models of power devices are only concerned with converting AC to DC. Advanced models have a built-in dimmer. That is, you can change the brightness of the lighting to higher or lower. For colored ribbons, you must select a model with a controller, or install it additionally. It is the controller that is responsible for changing the color, mode, blinking or the effect of the treadmill. And also an additional option for more expensive IPs will be the presence of a remote control from the remote control.

Very handy if you want to change color, brightness, dynamic backlight mode. Especially when you consider that the power supply is usually hidden from prying eyes for aesthetic purposes. The remote control is simply necessary to have access to all settings.The modes are controlled by radio channel or using infrared radiation, as, for example, in the remote controls of TVs and other household appliances. If you do not plan to work around the clock structure, take a closer look at the power supply unit with a switch. It is usually installed at the entrance to the system so that the adapter transformer does not work continuously even when the lights are off.

How to choose?

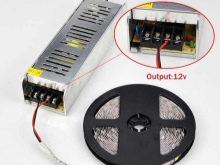

To choose a power supply, you need to decide on the purpose of the backlight. When the goal is clear, we choose a convenient mounting location. The most important point will be the length of the tape, so we carefully consider the footage. For selection, we take into account the maximum length of one segment. To find out which power supply you need for the diode strip, you need to calculate the power. We carefully study the packaging and look for the supply voltage required for the tape. It can be 12 V or 24 V. It is extremely rare to find the latest developments with an indicator of 36 V. This is the voltage that the power source should provide at the output, converting 220 volts from the outlet.

12 volts are safer than 24 volts and are the most widely available. The multiplicity of cutting in the former is about 3 LEDs, or from 2 to 5 centimeters. Sometimes you can find options with a multiplicity less.

A special marker on the tape will tell you where the cutting line is. Consider the frequency of these markers in order to calculate the length of the tape when purchasing. Twelve-volt tapes are sold in pieces of 5 meters.

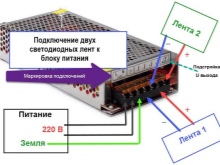

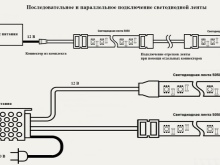

For every 5 meters of LED strip, a parallel connection to the power supply is used. This is the distance that the conductive paths of the LEDs withstand. If you simply connect the segments one to the other, you risk getting a much weaker glow at the end of the tape than at the beginning. In addition, such a design will quickly burn out due to a violation of technology. Therefore, the cuts are connected in parallel to one or more power devices. You can connect from one or both sides of the tape. The second option will evenly distribute the load on the current-carrying elements and increase the service life of the product.

To calculate the required length of wires, we start from the maximum possible length of one piece. The final selection is influenced by voltage losses depending on the length. 24-volt tapes lose voltage much less, which means that the section can be longer than 5 meters. In addition, since the current consumption is lower due to low losses, then the wires for connection will be thinner, as well as the weight of the entire structure.

Of the shortcomings, a narrow choice can be noted, because a voltage of 24 V is rare, and such tapes are more expensive in production. The next parameter is the power consumption per meter. The figure directly depends on the density of the diodes and their number. For example, if the board consumes 15 V, then with a length of 5 meters we get 75 W required for a uniform glow; 4 meters will require 60 watts, and so on. Let's assume that the total length of the illumination area is 20 meters.

To calculate the power of the adapter, we multiply the power consumption of a meter of tape by the length - and we insure ourselves using the power safety factor. We will take this coefficient as 1.3, that is, we will lay a 30% margin. In total, we have 15x20x1.3 = 390 watts minimum. Of course, the figure may turn out to be non-integer. Then we round it up to the nearest one. For example, up to 100 W, 150 W or 250 W. In our case, 390 is rounded to 400 watts, and so on. For colored tape, the principle of calculation will be the same. Consider the size of the adapter in order to choose a secluded spot for its location.

Connection tips

When the length and power are calculated, it is up to the installation. Pay attention to the markings on the tape itself. In addition to indicating the cut line, the icons will indicate the polarity "+" or "-" on each side of the cut. On multi-color tapes, polarity is indicated for each color, and the common plus is indicated by "V +".Fastening of LED strips is carried out on thin aluminum profiles. The material helps to dissipate excess heat generated during the operation of the backlight. This is to prevent burnout and degradation of diodes.

Especially important for high IP waterproof tapes. Such products are sealed with silicone to prevent exposure to the environment. Before connecting, the silicone is carefully and carefully cleaned from the contacts. Profiles are straight or angled, with opaque or transparent plastic diffusers. And also the diffuser protects the tapes from damage. If the distance between the LEDs is great, the matte diffuser helps to make the line smooth, to minimize the effect of individual light points.

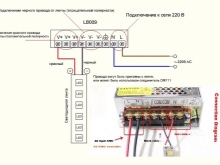

To connect the backlight, in addition to the tape itself, the profile and the control unit, we need wires to connect the segments. For a 12-volt tape, three-core mounting wires with a cross section of 1.5 millimeters are used, and for 24 V, 0.75 mm will be enough. First you need to supply 220 V power to the installation site. If you do not plan to equip the tape with a plug, then the light switch is mounted directly at 220 V, and not in front of the tape. This way the transformer will not work all the time even when the backlight is off.

Next, a power supply unit of the required power or several power sources is installed, depending on the chosen assembly scheme. Think in advance about the location of the block. Some models have considerable weight and size. You may need an additional shelf or niche for your device. For adapters with open housings, do not install in locations that block the ingress of cooling air.

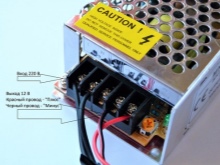

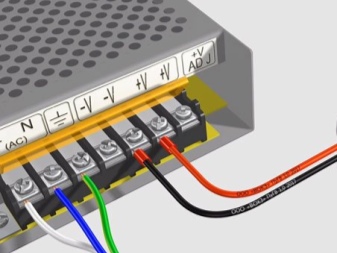

According to the designations on the power supply, connect zero, phase and ground to the unit. Most often, connectors are designated L, N and Re, respectively.

Next, the food is supplied to the tape itself. You can solder the wires or use special clip-connectors. The contacts are very fragile, do not overheat when soldering, the duration of the action of the soldering iron should not be more than 10 seconds. This will be enough for a delicate and delicate connection. Depending on the power of the tape, one-way or two-way connection is used. At long distances, the maximum possible lengths of tape segments are connected in parallel to the power supply with mounting wires. If you are using an RGB strip, keep in mind that the structure of the LEDs makes such strips dimmer than single-color strips. In one large diode, crystals of red, green and blue colors coexist.

Therefore, in different modes, not all light up at the same time, but only the necessary crystals. To control colors and light modes, you need a separate controller or a power supply unit with a built-in controller. An RGB amplifier can also come in handy. These are small devices that are mounted evenly spaced between tape lengths and are directly connected to a power supply. The amplifiers reduce the load on the controller and distribute the voltage evenly along the entire length of the colored tape. When installing a colored tape, first connect the power supply, then the controller, and then the tape to it. The principle of installing several segments is preserved, they use a parallel connection to one or more power supply units.

The comment was sent successfully.