Connectors for LED strips

Today, LED strips have long become an integral decorative and decorative attribute of many premises. But it often happens that the standard length of the tape is not enough, or you want to connect several tapes without soldering. Then a special adapter is used for connection, which is called a connector. This connector will be an excellent solution for a diode strip that you want to lengthen, or there is a need to connect several such devices into one.

Let's try to figure out what kind of device it is, what it is, how to choose it correctly and how to correctly connect several tapes with it.

What it is?

Connecting a pair of pieces of LED strip or connecting to a controller or power supply can be done in 2 methods: by soldering or using a special block equipped with terminals. The block is called the connector. And, in principle, from the name it is already possible to draw a conclusion about the functions of this device. The LED strip connector is a great alternative to a soldering iron that you need to know how to use. And besides, you need to know the features of this lighting technique, be able to work with solder and flux, and also know how to tin the wire correctly.

But the use of such a connecting device will be an excellent solution for those who want to save their time.

By the way, the connectors are used by professionals quite often, because these devices:

- are quickly installed;

- are versatile;

- allow you to provide reliable and high-quality contact;

- provide protection of the connection from dust and moisture;

- can be used even by a person without experience.

It should be added that problems with the wire when soldering arise often, and so you can use several connectors of the required types and assemble an excellent system. In addition, their cost is low, which will also be their advantage.

The only thing to remember is that when using any connection method for a single-color tape, it is better that its total length does not exceed 500 centimeters. And the reason here is in the characteristics of the tape itself, or more precisely, the permissible current strength for the operation of light diodes. Connectors are usually used when repairing tapes, as well as laying routes with complex configurations with bends of a small radius, that is, they are perfect, say, for an angle, if such a device should be passed through it.

Species overview

It is required to say that a device such as a connector can be divided into categories according to a number of criteria. Consider what they are in such aspects:

- bend level;

- connection method;

- number of contacts;

- dimensions of the working part;

- use in different conditions;

- Rated voltage.

By bending level

If we consider such a criterion as the level of bending, then in accordance with it there are the following types of connectors for LED-type strips:

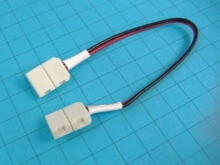

- no bend or straight - this is usually used to install straight sections of LED lighting mechanisms;

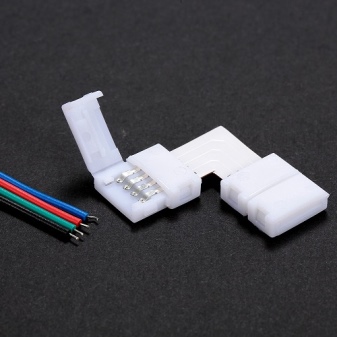

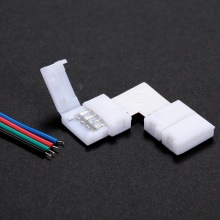

- angular - it is used wherever it is required to connect the device at a 90-degree angle;

- flexible - it is used for assembling tapes in areas that are rounded.

By connection method

If we take into account such a criterion as the connection method, then the connectors are divided into 3 categories:

- clamping;

- piercing;

- with a latch, which allows you to fix the top cover.

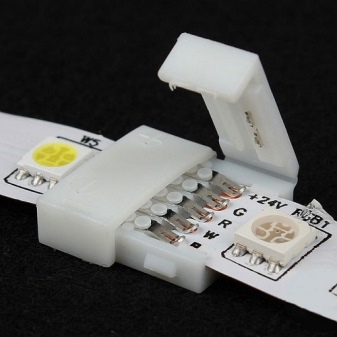

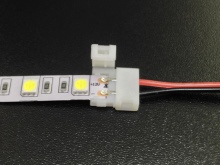

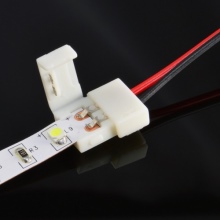

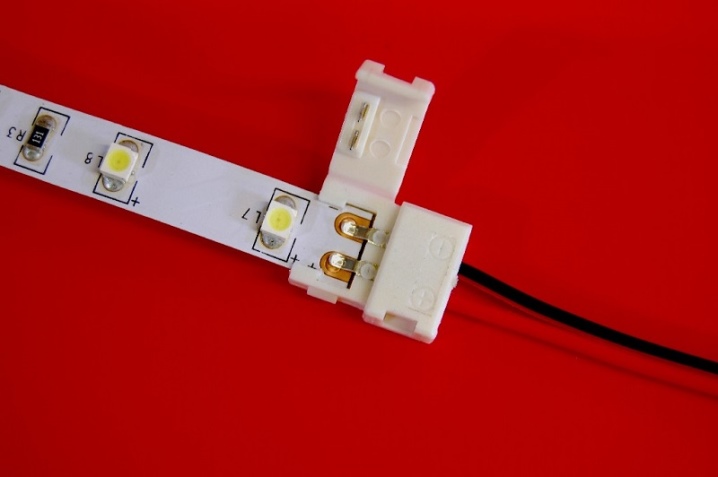

The latter type is usually used most often, because it makes it possible to splicate parts in a straight line. Externally, such devices have a housing with a pair of hold-down devices. Under them are the contacts of the spring-loaded type, where the LED strip is inserted.

Clamping or clamping models differ in the presence of closed mounting type plates with a cavity. An LED strip is tightly installed in such a device, after which it is well fixed. The advantage of this type of connector is its small size, but the disadvantage is that all the connection features are hidden under the body, and it is impossible to look at them through the connector.

Piercing models from the three mentioned categories are considered the most technologically advanced and are used as often as possible, because there is no risk of separation during operation and interruptions in the operation of the tape.

By the number of contacts

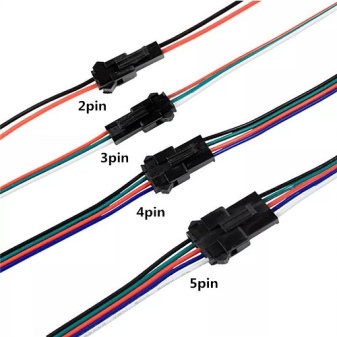

If we talk about such a criterion as the number of contacts, then there are connectors:

- with 2 pin;

- with 4 pin;

- with 5 pin.

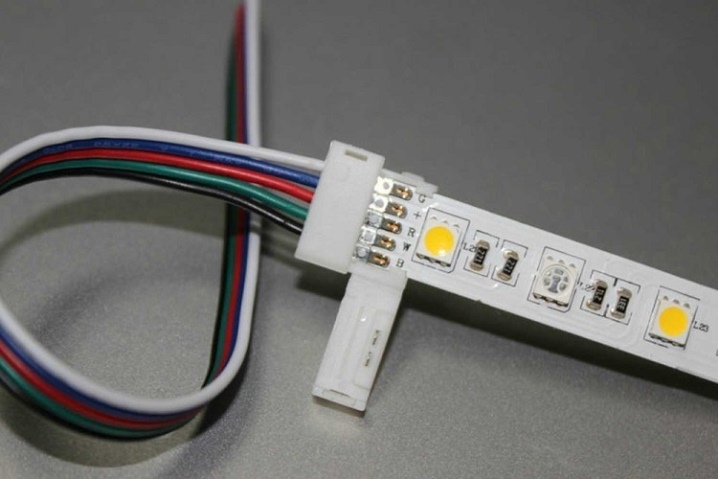

The first type of connectors is usually used for monochrome devices, but for RGB LED strips, 4 or 5-pin connectors are usually taken.

Fit to the width of the work area

According to this criterion, the connection clamps are in cross-section with the size:

- 8 mm;

- 10 mm.

Before choosing a connector according to this criterion, it should be taken into account that the width between the contacts is different for different models of LED strips, that is, the model that can be used for the SDM 3528 type strip will not fit the SDM 5050 at all and vice versa.

By rated voltage

If we take into account such a criterion as the nominal voltage, then there are models that work with voltage;

- 12V and 24V;

- 220 volt.

It is required to add that models designed to work with a voltage of 220 volts have a completely different structure and are not interchangeable with connectors for 12-24 V.

According to the principle of application in different conditions

According to this criterion, the connector can be:

- for connection to a power supply for conventional tapes;

- for connecting LED strips to a power source;

- for connecting parts of colored fixtures;

- for connecting any parts of monochrome tapes;

- angular;

- T-shaped.

Selection Tips

As you can see, there are very, very many different categories of connectors. How to choose a model that will be convenient to use and which will match the available LED strips?

This can be done if you are guided by the recommendations of specialists.

- Let's start with the fact that connectors make it possible to make a high-quality and simple connection of any type of tapes. There are connectors for both monochrome and multi-colored ribbons, equipped with any LED option. Most often, the considered category of devices is used with 12-24 volt tapes due to the fact that they are the most popular in everyday life and in various fields. It is necessary to use the connector when assembling complex luminous contours. And it is not always possible to assemble a complex glowing contour, therefore it would be better to connect several parts together.

- As it has already become clear, there are different connectors. So that the connection does not heat up too much, does not show resistance and does not stop the supply of current, the connector should be selected according to the operating parameters.

- You should pay attention to what type of connection a particular device is intended for. If it is direct, then the connection can only be made in a straight section without any bends. If the connection is not smooth and bends are required, then it would be better to use flexible connectors. They are used for both RGB and monochrome tapes.

- The next important criterion will be the marking indicating the type of LEDs for which the connector is intended. The most popular types of tapes are 5050 and 3528. They differ in a number of characteristics, from the wattage and size of the diodes to the amperage that flows through the wires and terminals. Naturally, they will have their own connectors. They will have a similar structure, because if you open the connectors 5050 and 3528, you can see a pair of contact groups and a pair of latches at the top. But the width of the connector for the 5050 is 1 centimeter, and for the 3528 it is 0.8 centimeters. And the difference seems to be small, but because of this, the device cannot be called interchangeable.

- The color ribbon connector models are equipped with 4 pins, which are used with RGB 5050 ribbons. But there are other types of tapes with different numbers of contacts. 2-pin are used for 1-color LED strips, 3-pin - for 2-color Multiwhite type, 4-pin - for RGB LED strips, 5-pin - for RGBW strips.

- Another important criterion is operating voltage. There are models for working with voltages of 12, 24 and 220 volts.

- Connectors are not only connecting, but also connecting and supplying. They are used to create a wired connection to amplifiers, controllers, and power supplies. For this, there are various connector configurations with corresponding sockets on the other side.

- You should also pay attention to such a thing as the protection class. Indeed, it often happens that tapes are mounted in places with high humidity. Therefore, the connectors must be properly protected. For residential and office environments, models with an IP20 protection class are available. And where the level of humidity is high, it is better to use products with a protection level of IP 54–65. If this point is neglected, the product may oxidize, which will affect the quality of the contact.

Features of operation

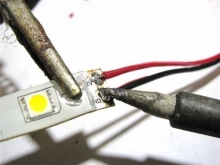

If we talk about the features of the operation of such devices, then an example should be given of how to use them to connect the LED strip. It should be said that you do not need to have anything at hand except the LED strip itself, scissors and the connector itself. Before cutting the strip, you should accurately measure its characteristics and determine the length. It should be taken into account that the number of light diodes in the cut-off parts must be a multiple of 4, which is why the parts may turn out to be slightly longer or shorter than the sizes that are needed.

After that, along the marked line, a cut is made between the adjacent LEDs so that there are mounting "spots" from two parts of the segments.

For tapes that have moisture protection made of silicone, you should clean the contact points from this material with a knife.

Then, having opened the lid of the device, insert the tip of the LED strip there so that the nickels fit snugly against the conductive type contacts. After the connector cover is snapped in, the same steps should be done on the other end of the piece.

In the process, you should check the polarity, because the colors of the cables may not coincide with the real picture. This procedure will make it possible to avoid problems and the need to redo the entire process again.

After all sections of the tape are connected to each other using connectors and the light structure is mounted, you should connect everything to the power supply and make sure that the resulting device is fully functional, all the light diodes are bright, bright and do not flash, and do not emit dim light.

The comment was sent successfully.