Features of LED strips in silicone

A simple LED strip is the lot of dry and clean rooms. Here, nothing will interfere with their direct function - to illuminate the room. But for the street and wet, wet and / or dirty rooms, where precipitation and washing are commonplace, tapes with silicone are suitable.

Peculiarities

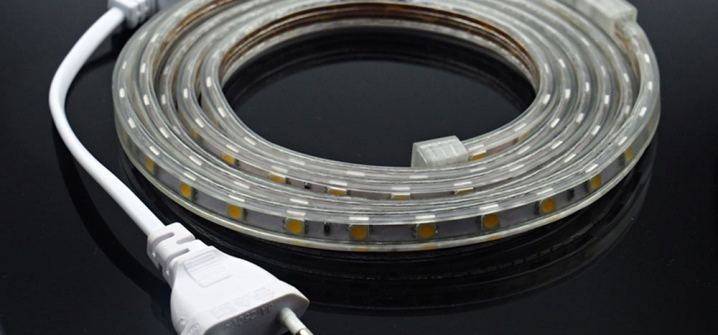

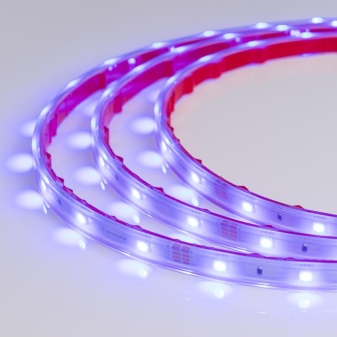

Light tape is a multilayer product. There is a place here for the main layer - a dielectric material, such as fiberglass with a microlayer (fractions of a millimeter), and current-carrying tracks (copper layer) with contacts for soldering, and the LEDs themselves with resistors (or primitive dimmer microcircuits), and a rubberized layer (depending on the model tape). All this is covered with a thick layer (up to several millimeters in thickness) of transparent, almost completely translucent silicone.

Of course, you can put an ordinary LED strip, not protected from moisture, in a flexible silicone hose - like those that gardeners and gardeners sometimes use. The disadvantage of silicone is that it cracks in severe (below -20 degrees) frost. Nevertheless, in a bath or bathroom, shower, where the requirements for moisture protection are special, it will justify itself 100 percent. You just need to seal the ends.

And so that moisture does not appear in a tightly closed space on the walls of the hose, you can put a piece of silica gel in the tube, fixing it so that it does not absorb light from the LEDs and does not catch your eye.

Silicone at positive (Celsius) temperatures, for example, at room temperature, retains not only water vapor, but also dust, as well as dirt formed from dust particles and water. In addition to insensitivity to weather conditions from spring to autumn in most regions of Russia, the silicone coating is flexible and elastic, which allows you to create inscriptions and signs from such a tape (when using mono and polychrome LEDs, for example, RGB). The class of moisture and dust protection is not less than IP-65. Mobility and flexibility makes it possible to hang these light strips on a surface with a relief of any irregularity.

The use of 220 volts imposes additional restrictions. Silicone LED strips are almost the only choice: a person, for example, in a bath is protected from the effects of accidentally leaking electricity - even when he forgot to install a residual current device. The absence of a transformer, stabilizer and other functional units that emit excess heat makes the energy consumption of the tape more economical. Only a mains rectifier and a smoothing capacitor are used here.

Species overview

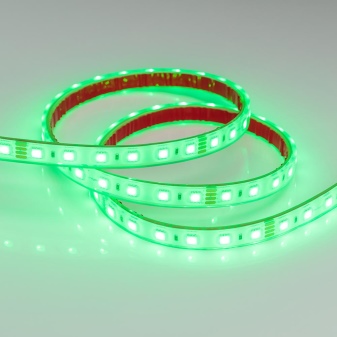

Light strips, regardless of the voltage supplying the assembly and the presence of moisture protection, are distinguished by several types. Tapes with simple SMD assemblies are monochrome - only red, yellow, green, blue or purple. Multicolor ribbons have triple assembly (RGB) - they require an external color control device. They are connected to a 220 volt network only through a power supply that steps down to 12 or 24 V.

Popular models

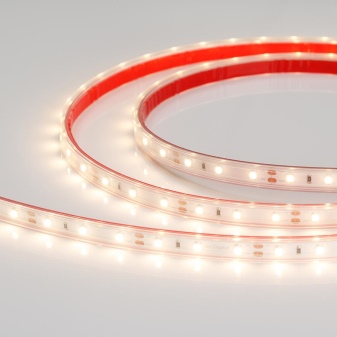

Some models - for example, based on light assembly SMD-3528 - are in the greatest demand. Of course, these are not the only LEDs that have found application as indoor and outdoor lighting in commercial buildings and venues. A typical specific component is the number of 60 LEDs per running meter of such a tape. IP-65 protection allows them to be used in humid and even dirty environments.

These light strips are produced by different companies, among the most common - Rishang firm... Class A indicates the premium status of this product: in addition to moisture protection, the luminosity (brightness) of the LEDs and a guarantee of continuous operation for a year attracts buyers who want to immediately invest in light elements that will not burn out in a month or two, but will last much longer.

This light tape is sold in 5 meter spools. The sector in the tape consists of 3 LEDs; these clusters are connected in parallel to each other.

The tape is switched on only through the transformer power supply, since connecting more than one LED in parallel will require a converter much more powerful than a simple line rectifier and capacitor resistors. If you connect the LEDs in parallel, each through its own resistor, as a result, the power loss on these resistors will increase, and such an assembly will be more expensive than the simplest unit consisting of 2 rectifiers and a transformer with a converter. The power of these tapes is about 5 W per linear meter, the operating current does not exceed 0.4 amperes per the same meter. The color palette is represented by the main four colors, as well as white glow at 7100 and 3100 Kelvin.

Light assemblies based on SMD-5050 LEDs have 30 LEDs per linear meter. They are produced by Song. Double-sided tape is often supplied with such tapes, which allows you to mount these elements on glossy and hard surfaces, the material of which does not "dust" by itself. The warranty period is no more than a month, obviously, the violation of the correct calculation affects. Belong to the B-class.

The tape is cut by 10 cm, connected through a transformer power supply, released in 5-meter coils. The light power reaches 7.2 W, the current consumption is 0.6 A. It is easy to guess that 12 volts are required. The directional pattern of the light flux for each LED is "flattened" and equal to 120 degrees.

By connecting from 18 to 24 segments of 1 m in series, you can use them as a 220-volt lamp. A powerful high voltage mains rectifier is required. A capacitor with an operating voltage margin of up to 400 V is used to smooth out 50 or 100 Hz ripples.

For serial connection, a special wiring is performed - using single and double wires. It is recommended to mount such a luminaire on a rectangular panel.

Applications

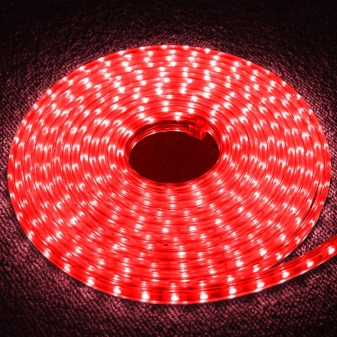

12 volt street tapes, which do not have silicone protection, are used only in a special transparent hose, if possible, plugged at both ends. The fact is that cold air in winter, cooling the tube outside, causes condensation to form inside during the day when this light strip is turned off. To eliminate this, after inserting the tape and removing the wires, the tube is sealed, for example, with hot glue or sealant.

Protected silicone-coated tapes do not need additional protection against rain and fog - cutting by half a meter or a meter is carried out only by marks where the coating is thinner: special marks are applied here and reinforced conductive paths are used for soldering wires.

Diode light tape is an attribute of outdoor advertising (signs and billboards, displays). From the inside, it is used as wall and ceiling lighting - along the perimeter and straight lines, dividing the ceiling of a large area into sectors.

Decorative illumination of pillars, trees and buildings, structures from the outside allows you to create any colors and palettes - this is how streets, grounds and roads of all kinds are decorated.

How do I cut the ribbon?

The manufacturer places cutting lines (points) on 12-volt light strips every 3 LEDs. Colored tapes for the same voltage are marked with a marker dot every 5 light elements. For 24 volts, these steps are 6 and 10 LEDs respectively. Manufacturers group double LEDs for 220 volts into sequential clusters of 30 pieces, and single ones - 60 pieces each. Unprotected (completely flat) strips are cut with simple scissors, waterproof (frost-resistant, in a round or semicircular sheath) - using reinforced (metal scissors).

The comment was sent successfully.